19.09.2025

TCM Showcased Key Advances in Carbon Capture at IEAGHG Conference

At the IEAGHG Conference in Marseille, the Technology Centre Mongstad (TCM) presented new results from industrial-scale carbon capture testing and highlighted how machine learning can improve environmental monitoring.

The contributions reinforced TCM’s position as a leading test facility for accelerating global carbon capture solutions.

Large-Scale Testing with CESAR 1

In one presentation, Industrial Scale Carbon Capture Technology Testing at Technology Centre Mongstad: Results using CESAR 1, TCM’s Koteswara Rao Putta presented results from large-scale testing of the CESAR 1 solvent. With global CO2 emissions continuing to rise—surpassing 40 billion tons in 2024—the need for proven and scalable capture solutions was underlined.

“Amine-based capture technologies remain at the forefront of carbon mitigation strategies,” said Putta. “At TCM, our mission is to systematically test, validate, and improve these systems so they can be deployed with confidence at commercial scale. By doing so, we help reduce technical, environmental, and financial risks for industry.”

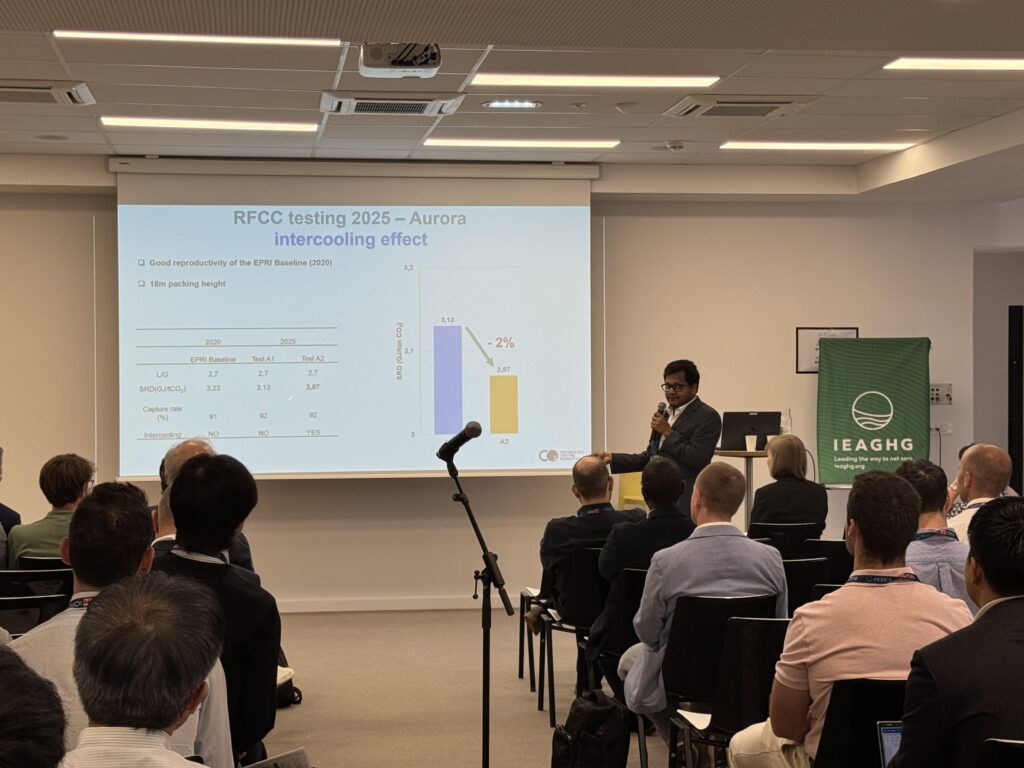

The CESAR 1 campaigns at TCM provided crucial data for industry partners and research institutions alike, supporting the scale-up of capture systems from pilot to industrial demonstration. These efforts formed part of wider European collaborations, such as the AURORA project, aimed at bridging the gap between laboratory innovation and full-scale deployment.

A complementary presentation by Ahmad Wakaa focused on detailed learnings from more than 6,000 hours of CESAR 1 testing in 2020, including thermal reclaiming and emission monitoring during RFCC flue gas operations. The results demonstrated high efficiency in removing degradation products, metals, and heat-stable salts, with minimal solvent loss and strong capture performance.

“By combining operational experience with in-depth solvent analysis, we are able to document both the robustness and the limitations of advanced solvents like CESAR 1,” explained Wakaa. “This knowledge is vital for operators who plan to run capture plants reliably and sustainably over long periods.”

Machine Learning for Smarter Emissions Monitoring

The presentation, Exploring Predictive Emissions Monitoring of Ammonia at TCM Carbon Capture Plant Using Open-Source Machine Learning Libraries, was delivered by Fred Rugenyi. This work explored how advanced data analytics can improve environmental performance by predicting solvent-related emissions, such as ammonia.

Using TCM’s extensive historical datasets and machine learning tools like Sci-kit Learn, the study compared different regression models to forecast emissions. The Random Forest model delivered the most accurate predictions, opening the door for smarter monitoring and mitigation strategies in real-world operations.

“Machine learning provides us with a powerful tool to understand complex plant behaviour,” noted Rugenyi. “By predicting emissions, operators can take preventive action to reduce environmental impacts while improving plant reliability.”

Together, these presentations underscored TCM’s role as a global testbed for carbon capture innovation, advancing both process technology and digital solutions that will be vital for achieving net-zero ambitions.