He is responsible for modifications to the facility

Kjetil Hantveit was involved in building the plant and made a come-back in 2014 in the position of Modification Manager.

Technology Centre Mongstad (TCM) has a 10-year anniversary in 2022. We celebrate ourselves with interviews with people who in various ways have had impact on the business in these years.

– Why did you apply for a position at TCM?

– I got a phone call from former project leader Sjur Brandtun to take the position as leader for modifications at TCM while I worked on a project for Equinor in the North Sea. It was tempting, and not long after I recieved a proposal for a contract. The motivation for saying yes was that I knew the skills at TCM from the construction period, and knew I got to work in teams with good people. In addition, there was also jubilation at home since this meant that I would get a job within normal working hours. Travel from the farm on Hantveit in Gulen on the north side of Fensfjorden has never been a problem. February 1, 2014, I was ready for duty.

– How was your first meeting with TCM?

– I remember it was nice to greet old acquaintances in the modification department and those who had started there after the facility was put in operation. They took me on a tour of the plant and explained what had happened in the first two years. Then we sat down and discussed the tasks we had ahead of us. It was a good day for a «half-newcomer».

Kjetil Hantveit leads the work with modifications at TCM’s plant and is member of the leadership for the company.

– What will you highlight as the most rewarding and interesting work you took part in at TCM?

– At TCM, every activity and test campaigns live their own lives. What has made the job interesting is that we have managed to make the adjustments to the plant that are necessary for every new technology that has been tested. Thus, there will be groundbreaking work every time, and I can honestly say that no one has left here without having been allowed to do what they had planned before they arrived. Sometimes problems arise that are solved ad hoc. We manage to solve them with strong will and good effort, and excellent collaboration with the technology suppliers. That they get to test what they have to within their schedules, and are satisfied with the results, is incredibly satisfying both for me and the entire TCM team.

– Are there projects or events you remember back with special joy?

– In the first operational period, there were challenges to test with both flue gas sources from the refinery in the amine plant, ie both flue gas with about 3.5 percent and about 20 percent CO2 content. We thought that installing a new large filter allowing filtration of particles before the gases entered the process would be a good solution, but the professional bodies we sought advice from were sceptical. They thought the filter would clogged up quickly. But despite that, we chose to go for the solution we had in mind. We first did a pilot to see how it went, and it worked well. Then we were happy – and a little proud. The filter we obtained six years ago is still in use today.

– What do you think is most challenging about your work at TCM?

– For me personally, the job at TCM has been a long professional upswing. But for TCM as a company, it is a problem that the funding allocated for each operating period are limited to short periods. This makes it difficult to plan activities far in advance. It also makes it demanding to recruit new people and keep the ones we have. For TCM, it is also a challenge that the plant is no longer new but has been in operation for ten years. When operations are only guaranteed for three years in a row, it will be difficult to get approval for technical upgrades. They are needed for TCM to maintain its position as a world leader in testing CO2 capture technologies.

– When you tell your friends and acquaintances about the business at TCM, what do you emphasize as the most important utility value?

– Then I say that as long as one believes that the changes in nature and the environment are created by man, then we must use everything we have in the toolbox to stop development. Carbon capture and storage is one of these tools. The fact that we in Norway have the world’s largest test centre for technologies and cutting-edge expertise in the field is not only of great value nationally – but for the global climate challenge.

So we in our country throughout all ten years have struggled with the fact that the plan for TCM was to get full-scale purification of CO2 from the thermal power plant at Mongstad, of which there was none. Exactly that has not taken hold in the same way internationally. The ones I surround myself with know about and understand what we are doing. But I hope the marking of ten years of operation can make it better known among most Norwegians that testing at TCM is a prerequisite for safe capture of CO2.

– What is your wish for TCM the next ten years?

– Until now, TCM has been a “catch and release” facility. My wish is that in the years to come we can also take CO2 which are caught and make use of it as an input factor in various industrial productions. Here, with our expertise, we can be a driving force and catalyst to help those who have good ideas. At the same time, testing of new technologies must continue. As in the automobile industry, we work to reduce emissions and present increasingly energy-efficient solutions, and that takes time. TCM has such an absolute future ahead of it!

Name: Kjetil Hantveit

Age: 45

Education: Certificate in electrical engineering, as well as ambulance driver

Marital status: Partner, three children

Affiliation with TCM: Responsible for mechanical completion of the facility 2009 – 2011, Manager of the modification department 2014 – , member of the leader group 2020 –

Present position: Modification Manager at TCM, hired from Omega Power

– When you generally look back on 10 years of business at TCM, what do people that worked at TCM or still are working there have particular reason to be most proud of?

– I mean one should be careful about feeling successful. Success is best measured in praise from others. But that we have managed to get companies and research institutions from large parts of the world to come to Mongstad is an achievement. This is not only due to the fact that the test facilities are good, but that they are received by people who really know what they are doing and help them further along the way. One should keep in mind that even though the test campaigns are subsidized by the owners of TCM, it is not free to come here. Norway is a high-cost country, and the expenses they have to get equipment and personnel to Mongstad are not small. The fact that they are still investing resources in testing and cooperation with TCM in the US, Asia and Europe is proof that we are useful and have good offers.

Kjetil Hantveit has busy days at TCM.

TCM; educates buyers and users of CO₂ capture technology

TCM, is not only the world’s largest and most advanced test center for post-combustion CO2 capture technologies but also has been proven to be a technology neutral partner that exists to facilitate the mass deployment of the technology worldwide.

Advisory Services established in 2020

For ten years now, TCM stands as a valuable asset for the technology vendors around the world that aimed to verify and demonstrate their technology, including energy consumption and other cost saving claims.

Equally, if not more important is that TCM is also the only amine-based CO2 capture plant, at such large scale, that operates non-proprietary campaigns and produces unique public knowledge that has been distilled into fundamental understanding of the technology. Centered around this knowledge, TCM launched Advisory Services, in 2020 and since then flagship CO2 capture projects around the world such as Longship but also individual technology buyers and project owners are coming to TCM to acquire access to key learnings that will enable them to become educated buyers and users of CO2 capture technology.

Introduction to TCM

TCM is owned by the Norwegian State (managed by Gassnova, 73.9%) together with the industrial partners Equinor (8.7%), Shell (8.7%) and TotalEnergies (8.7%). TCM’s owners are dedicated to make a difference in combating climate change and they do so, among other, by investing throughout the full CCS supply chain as they are also the largest stakeholders in the Northern Lights projects, the storage part of Longship.

TCM has been recognized as an international leading competence center for CO2 capture that offers:

- Test facilities in industrial conditions, unparalleled in scale and flexibility, matched with a highly qualified workforce, open and neutral for all technology developers and vendors around the world.

- Public access knowledge center that brings together academic and industrial players with the shared purpose of improving the feasibility and deployment of the CO2 capture technologies.

- Advisory Services that turn the vast amount of knowledge and experience accumulated from non-proprietary campaigns into comprehensive learnings for industrial applications, priceless to all technology buyers and users.

More than NOK 6 billion have been invested in construction and development of TCMs test facilities at Mongstad. The site consists of an amine plant, an ammonia plant, and a site for emerging capture technologies. All three have access to two industrial flue gas sources from Equinor’s refinery and gas fired Combined Heat and Power (CHP) plant at Mongstad. The CO2 content of the two industrial streams allows TCM to test CO2 capture both at its thermodynamic limits with the low CO2 concentration of CHP stream, and at the complex chemistry conditions that the refinery stream is creating in the process. The existing capability to recycle and dilute enable us to also imitate emission gases of other industries such as waste incineration.

TCM operates under an emission permit from Norwegian regulators, ensuring safe and verifiable results in every aspect of operation. TCM together with the Norwegian authorities underwent a long journey, started before its operations in 2012, to develop the emission permit process for an amine-based CO2 capture plant. This process is strictly followed for every new campaign at TCM. Moreover, the learnings and approach taken on emission permitting may be employed for most full-scale industrial capture projects.

The key players

Since TCM started operations in 2012, most of the key players in the CO2 capture market have tested, derisked and demonstrated industrial scale technologies at its facilities. As it is shown in Figure 1, Alstom, Shell Cansolv, Aker Solutions, CCS Limited, ION Engineering, Fluor Corporation and Mitsubishi Heavy Industries have all conducted thorough testing of their proprietary solvents at TCM’s Amine and Chilled Ammonia plants. TCM has given full priority in supporting the technology developers and vendor companies during the 28,000 hours of total proprietary testing in almost ten years.

Figure 1. Vendors conducted proprietary testing with their own technology.

In 2021, TCM started operations of its Site for Emerging Technologies which is designed for smaller scale testing of lower Technology Readiness Level (TRL) technologies when compared to the TCM amine facilities. MTR and TDA were the first to complete the demonstration of their technologies at this site. Three more projects are planned to test their technology until the end of 2023, when the current operational agreement of the TCM JV is to be renewed. More information on TCM’s Site for Emerging Technologies.

Open scientific campaigns

Since 2013, TCM owners funded, together with EU and US DoE, numerous open scientific campaigns, with non-proprietary solvents (Figure 2). These campaigns were conducted in partnership with recognized universities and research organizations around the world addressing typical technical pitfalls observed in CCS projects such as:

- Chosen technology does not match flue gas characterization resulting in degradation and emission permit issues.

- Actual operating environment often not tested.

- Lack of validated simulation and analytical models and prediction tools.

Figure 2. Open scientific campaigns with non-proprietary solvents.

Based on more than 20,000 hours of non-proprietary testing TCM has accumulated world-leading know-how on mitigating the above risks as well as other risks related to operations such as:

- Forced use of Oil & Gas industry standards which results in high costs.

- Risks and failure modes of key equipment have not been systematically identified.

- Long term effects of corrosion and fouling of the plant on capture performance and energy consumption.

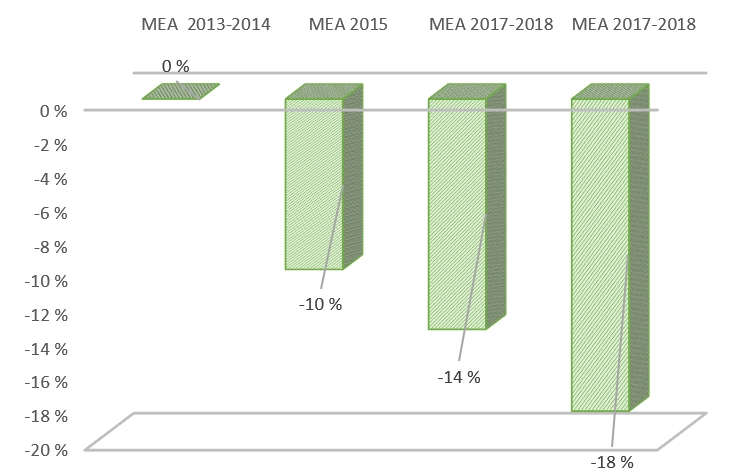

TCM has demonstrated reduction in cost

A series of testing campaigns that was carried out by TCM and its owners in the amine capture plant aimed to study various cost saving operating options relevant for combined cycle gas turbine plants. This was one of the first times that such a structured campaign was executed at a scale that can provide relevant basis for scale up and industrial design. The results, as illustrated in Figure 3, showed encouraging cost reduction potential for energy consumption and capital cost of the amine plant. Detailed descriptions of the test campaign and analysis of the results are available here.

Figure 3. TCM demonstrated reduction in cost of CO2 avoided compared to earlier campaigns.

TCM’s Advisory Services are facilitating the “translation”

TCM “translate” all the aforementioned knowledge from the TCM scale to the industrial projects. Reports summarizing key learnings, tailor-made advisory projects and workshops are some of the ways that are serving as the vehicle that transfers knowledge. Some examples of how TCM’s experts are providing valuable contribution to the different phases and milestones of the CO2 capture projects are listed below:

Examples of Advisory Services Standard Offerings

Generic CO2 Capture prosess

- Key lessons from TCM on solvent and waste handling.

- Key lessons from TCM maintenance.

- Key lessons from TCM start-up and shutdown.

- Key lessons from TCM operation on thermal reclaimer.

- Summary of TCM learnings on foaming.

- Key lessons from TCM process control.

CO2 Capture plant design

- General philosophy for CO2 capture plant design.

- Guidelines and recommendations for absorber design.

- Guidelines and recommendations for regenerator design.

- Guidelines and recommendations for thermal reclaimer design.

- Guidelines and recommendations for water wash systems design.

- Guidelines and recommendations for heat exchangers design.

Operational Academy

- Key lessons from TCM on solvent and waste handling.

- Key lessons from TCM maintenance.

- Key lessons from TCM start-up and shutdown.

- Key lessons from TCM operation on thermal reclaimer.

- Summary of TCM learnings on foaming.

- Key lessons from TCM process control.

Examples of tailor-made Advisory Services Projects

- Smart review of pre-feasibility and feasibility study.

- Review of design basis.

- Develop preliminary process simulation and sensitivity analysis, based on non-proprietary solvents, for bench-marking purposes.

- Develop preliminary design of key equipment, based on the above model, for bench-marking purposes.

- Support in piloting phase (advice on test plan, on lab procedures and test results review).

- Support in technical & HSE related risk identification.

- Participate & support in HAZOP studies.

- Support in specific questions on maintenance, spares etc.

- Operator training.

- Support in commissioning and start-up.

- Support in troubleshooting (emissions, thermal performance, solvent degradation & reclaiming etc.).

- Other

TCM’s Advisory Services were launched in 2020 and despite the challenges of the pandemic, managed to develop an impressive portfolio of projects as it is illustrated on Figure 4 below.

Figure 4. Advisory Services Projects provided in various CCS facilities in Norway and other European Countries.

Supporting Longship

Support of “Longship” which is the biggest climate project ever, undertaken by Norwegian industry has been one of the main focus areas of our team. TCM delivered Advisory Services to both main capture projects of “Longship”. Contributed with its expertise in early studies of Hafslund Oslo Celsio`s planned Waste to Energy plant, a full-scale project at Klemetsrud in Oslo, and by participating to HAZOP assessment of the capture project of Heidelberg Materials Brevik cement factory of Heidelberg Cement. We also offered our services to Statkraft, Kvitebjørn Varme and Hoegh LNG, in important Norwegian CCS projects. More information on CCS Norway and “Longship”

TCM also provided advisory services to OGCI (Oil and Gas Climate Initiative), the USD $1 billion climate fund founded by the world’s largest energy companies. Some examples of other projects that have requested TCM’s support in interesting studies are Net Zero Teesside, Phillips 66 and SSE Thermal, all leading projects in UK CCS arena.

At the moment, TCM and the Advisory Services team are supporting more projects in Europe and Norway and are excited with the positive shift that is happening around the world in political, social and industrial level. CCS is now recognized as one of the ways to fight against climate change and TCM will be in the forefront of that fight!

She got to work with something she is passionate about

Anne-Berit Hjorth Viken was Operation Manager at TCM for eight years. She is grateful that she got to work with something she is really passionate about.

Technology Centre Mongstad (TCM) has a 10-year anniversary in 2022. We celebrate ourselves with interviews with people who in various ways have had impact on the business in these years.

– Why did you apply for a position at TCM?

– I started my work with CO2 capture in Equinor in 2008, as an assistant project manager for the planned full-scale plant at Mongstad. After four years of commuting to Stavanger, I had six months’ leave. Then the position as operation manager at TCM appeared, which for me was a perfect opportunity to continue working with CO2 capture which I was very interested in. The interview took place in Equinor, and I also had a good conversation with Tore Amundsen, who then was Managing Director of TCM. I was very happy to get the job as Operation Manager.

At work for TCM during the GHGT conference in Melbourne, Australia in 2018.

– How was your first meeting with TCM?

– With my background from working on the full-scale project, I knew quite a bit what I was going into. I still felt a certain excitement when I entered the administration building in December 2012. I was well received, in my office there were flowers as a nice welcome. The amine plant had been operational for some time. The CAP plant was in operation, but was stopped at the end of the month and prepared for modifications prior to a new start-up a few months later. It was more than enough to work with and dig into; innovation with new and untested technology was demanding. But I had very good support from many skilled and committed colleagues.

– What will you highlight as the most rewarding and interesting work you took part in at TCM?

– The most important for me was to be involved in the implementation of projects with a global perspective. Succeeding in carbon capture is important for the whole world. For both me and my colleagues at TCM, it has been incredibly rewarding to work with so many good and dedicated people from the technology providers and in the research environments, and to experience that our efforts for the CCS community are appreciated and make a difference. Being able to document that CO2 capture is both safe and feasible is very important. I think it has been interesting to register through the many visits to TCM, that so many people from different countries, universities and research organizations are interested in what is happening at TCM. It gives hope for the future.

Anne-Berit Hjorth Viken remembers the signing ceremony at TCM in 2017. The picture shows the then Minister of Petroleum and Energy, Terje Søviknes, together with Svein Olaf Nesse from Shell, Trude Sundset from Gassnova, Irene Rummelhoff from Equinor and Pierre Bang from TotalEnergies.

– Are there projects or events you remember back with special joy?

– I especially remember when the owner companies in 2017 decided to extend the operating period for TCM. One owner decided to leave and a new one came in, and the agreement was signed at Mongstad with all employees present. It was a moment of celebration and recognition for the work we had done in the previous five years.

Another memorable event was when representatives of NETL, which coordinates the US authorities’ activities for carbon capture, at «Milestone Mongstad» gave Norway and TCM their unreserved recognition. Normally, technologically strong USA would have built such a test facility themselves, but the cooperation with us has made it unnecessary.

I would also like to emphasize the commitment that has characterized the business. TCM has a small and vulnerable organization, which has nevertheless mastered solving the many challenges along the way. The good feedback from the customers has rightly made us proud.

Finally, I think it is gratifying that TCM’s strong focus and expertise on HSE and emissions issues, has created safety and support for the activities in the local community. The fact that we have avoided creating local problems in the work to solve a global challenge, has been and is very important. TCM has put HSE and emissions issues on the agenda in the global CCS community. TCM is among the foremost in the world in emissions measurements and instrumentation for documenting emissions from CO2 capture. In this area, TCM has built a strong and professional environment.

– What do you think was most challenging about your work at TCM?

– What I am thinking of in this connection is that TCM has not received the same recognition in Norway as in the world. We had deserved better!

Personally, I also think back on a special event in advance of a test campaign as a bit challenging. An operational problem was discovered and was not responded to quickly enough. I learned that we must ensure adequate dialogue and information from the technology provider at an early stage so that we are well prepared and can take our precautions. But we sorted out the problem and got control of the situation.

– When you tell your friends and acquaintances about the business at TCM, what do you emphasize as the most important utility value?

– For me, it is important that in a conversation I can look my neighbor in the eye and say that what I am doing is safe. My experience is that a humble approach is best, namely, to admit that technology development takes time, and that safe capture of CO2 is a demanding job. Therefore, TCM is necessary to test and verify that technologies actually work, which in turn will contribute to solving the climate problems. In addition, I also think it is important to emphasize that working with carbon capture is both meaningful and enjoyable.

– What is your wish for TCM the next ten years?

– For me, who for several years has followed the development of capture and storage of CO2 closely, it is enormously satisfying that full-scale facilities are now being built both in Norway and around the world. It would not have happened without TCM. My hope is that TCM will continue to be an important part of this value chain, both through testing of new technologies and advice project developer and operators who will build and operate large facilities. A stronger collaboration between the Longship project and TCM will strengthen the expertise Norway has built for the entire CO2 value chain, which can be shared with the world.

Name: Anne-Berit Hjorth Viken

Age: 60

Education: Master of Science in chemical engineering from NTNU, Trondheim

Marital status: Married, two children

Affiliation with TCM: Operation Manager, seconded from Equinor, 2012 -2021

Present position: Project Manager PPC at Equinor’s refinery at Mongstad

– When you generally look back on 10 years of business at TCM, what do people that worked at TCM or still are working there have particular reason to be most proud of?

– It is a lot! But if I have to mention one thing, it must be that TCM through all these years has managed to acquire new customers for the facility. That was not obvious after the opening in 2012. That TCM, in addition to continuous operation of the amine plant, has also been given an area for testing new modular capture technologies, is very exciting. It has given the company a new and important business opportunity.

He attends «the school of life» at TCM

Technology Centre Mongstad (TCM) has a 10-year anniversary in 2022. We celebrate ourselves with interviews with people who in various ways have had impact on the business in these years.

Øyvind Ullestad became part of the team in 2011 and is a key person when it comes to measuring and analysis of tests performed at the plant.

– Why did you apply for a position at TCM?

– I had a good job at the Mongstad refinery with analysis of oil, petrol, and diesel. But when a position at TCM was advertised, I thought it was time to try something new. The challenge of building something completely new was simply too exciting not to. Contributing to the establishment of an apparatus for the analysis of flue gas professionally was very interesting, and with the possibility of retreating to Equinor, I had nothing to lose by seizing this opportunity.

– How was your first meeting with TCM?

– I came to a room that was completely empty. Here I and a colleague, who started at the same time, were to create a workshop with everything needed for equipment to do good analyzes when the plant came in operation. This was by no means surprising. But we knew that if we missed and things did not work, then there was no one to yell at but us. Therefore, it was important to be involved in and understand the entire project, and to check that everything that was purchased matched TCM’s needs. For someone who has mostly gone to the «school of life», this process provided a lot of interesting lessons.

– What will you highlight as the most rewarding and interesting work you took part in at TCM?

– To me, it has been learning ways to make measurements of CO2 emissions as accurately and precise as possible. The authorities’ discharge permit places strict demands on TCM and has been and still is an important driving force for how the plant is operated and results are analyzed and reported. The first years were especially interesting, because we had to run two plants with different technologies. Then there were five of us in automation who shared the tasks, while now only I work full time with analysis with support from one another in about half a position.

Øyvind Ullestad in the richly equipped analysis house at TCM for measuring various emission parameters.

– Are there projects or events you remember back with special joy?

– In the beginning it was fun because we constantly had to find solutions and trust ourselves. There was no one to ask because the capture of CO2 on our scale was completely new. It gave me many, good a-ha experiences. But even though much has gradually become routine, each test campaign still has its own life. With ever new and more refined technologies, we must constantly adapt and think new to deliver high-quality analyzes. The fact that we have acquired many more and better meters along the way, has also contributed to a fine learning curve. It has also been nice to be in dialogue with the customers when they sometimes have specific questions about the analyzes I have provided.

– When you tell your friends and acquaintances about the business at TCM, what do you emphasize as the most important utility value?

– My sigh of relief is that we at TCM have far too little managed to tell people in Norway the importance of what we are doing to preserve the globe. In Eastern Norway, many believe that TCM was closed after the “moon landing” had failed. In the United States, on the other hand, we are admired.

My simple story is that it is not difficult to capture CO2. But doing so with low energy consumption and minimal emissions is difficult. Therefore, both Norway and the world need TCM to test that the technologies work.

– What is your wish for TCM the next ten years?

– I will retire in two years to run the family farm near Mongstad full time. But I hope our owners will decide to run TCM for both ten and twenty years to come. Development of new technologies for carbon capture is necessary to save the world. If not, future generations risk having to wear swimming trunks all year round.

Øyvind Ullestad was among the participants during the opening of TCM in 2012. The picture shows when the facility appeared behind the big stage, with Sarah Montague as presenter.

Name: Øyvind Ullestad

Age: 59

Education: Certificate in electrical engineering

Marital status: Married, two children and six grandchildren

Affiliation with TCM: Senior Engineer in Automation, seconded from Equinor, 2011 –

Present position: Senior Engineer in the department Lab. / Operation at TCM

– When you generally look back on 10 years of business at TCM, what do people that worked at TCM or still are working there have reason to be most proud of?

– That we have become able to plan and carry out test campaigns to the great satisfaction of our customers. For my part, the contribution has been to deliver correct figures and values of what is desired and expected. I’m proud of that!

– The role of the Norwegian state in TCM is exemplary

– The role the Norwegian state has taken in the building and operation of TCM is remarkable and exemplary for other European countries, says Anne Brisset. She is the Manager of Stavanger Research Center of TotalEnergies and member of the company meeting (board) of Technology Centre Mongstad DA (TCM).

TotalEnergies has been a co-owner of TCM since 2017, together with Equinor and Shell. The Norwegian state is the main owner with a share of 73.9 percent.

Anne Brisset emphasizes that the Norwegian state invested a lot in the building of TCM and so in the development and derisking of carbon capture worldwide. Its strong participation in the structure costs of TCM made feasible the participation of owners. – The government, through Gassnova, is playing its role as a “strategic state” to build the world of tomorrow through its strong involvement in the construction of such a structure and participation in the operating costs. Such a role is remarkable and exemplary for other European countries, she says.

An amazing platform for gaining knowledge

According to TotalEnergies, TCM since its startup has acted as a catalyst for the deployment of Anthropogenic CO2 capture. Such structure combining process at large scale with R&D problematics was a prerequisite for implementing commercial units which will help the industry in reaching its decarbonation objectives.

– Because of the high scale of the amine plant, TCM is a demonstrator of the performances of solvents developed by proprietary vendors and a compulsory stage in their development process for validating further commercial deployment.

– TCM is an amazing R&D platform for gaining knowledge, understanding, for developing tools, competences and trust in the solvent-based post combustion CO2 capture processes. Being owner of TCM is regarded as being at the outpost of all the actual efforts to accelerate the reduction of GHG (Greenhouse gas) emissions, Anne Brisset puts forward.

Anne Brisset represents TotalEnergies in the Company Meeting (Board) of TCM.

Has enriched the understanding of and development of CCS

The collaboration between the owners of TCM has in several ways enriched TotalEnergies’s understanding of and development of CCS technology.

– TCM is both a learning and training center for our seconded personals but also for the technical people working on our on-going projects.

– TCM is also addressing many challenges necessary to overcome for a wide deployment of carbon capture in the industry. As a non-exhaustive list, here below is our consideration of the benefits and usefulness of TCM outputs:

- Learning and training through the expertise of TCM personal, the results of the campaigns, and the detachment of our personal. «TCM can be viewed as a trainer center before conducting a plant on our asset.»

- To benchmark technologies and challenge technology vendors

- To accelerate the deployments of technologies in our companies, on our partner assets

- To promote and help the deployment of technologies of some vendors we are supporting

- To gain operational experience on a high scale unit: start up, shut down, instrumentation, analytics, corrosion, solvent degradation and vendor specific technologies.

- To derisk our industrial deployment on carbon capture, in particular the environmental concerns related to emissions. Public acceptance will require to understand, mitigate and control emissions. TCM has developed over the year a very high level of expertise on this subject.

- To develop and validate simulation tools, real time plant control

Still a need for reducing the cost of carbon capture

The Partnership’s Agreement describes five objectives for TCM, among them to reduce cost and risk related to deployment of CCS, and to facilitate wide international deployment of CCS technologies. Anne Brisset says that TCM has made a big push to the development of the carbon capture market.

– After 10 years, the market is there, and technology deployment is accelerating. But there is still a need for reducing the cost of carbon capture. Through the multiple campaigns performed on TCM amine and chilled ammonia plant, most of the most mature advanced amine solvent were tested and derisked. The results of these campaigns have clearly facilitated carbon capture deployment all around the world.

– Our opinion is that TCM has contributed to development of technology vendors and subsequent competition, and also to wide knowledge sharing where relevant for CCS. TCM is a neutral testing site which help vendors in maturating their technology. It clearly encourages emulation and competitions between the main vendors. Since the beginning, the company has brought a lot to the international community of CCS by developing and maintaining a strong publication activity. Tens of papers have been published and presented in conferences, workshops. TCM has been engaged in numerous collaborations with academics, vendors, service companies, end users. Owner’s campaigns are the basis of this knowledge sharing. TCM appear today has having the expertise but also the ability to share it through publishing activities but also the recent development of the advisory services.

Great value for the participants

Anne Brisset points that several outputs of TCM are keys for participants to become informed buyers and end user of CO2 capture technology, which also is an objective for the company:

– TCM is in continuous contact with most of the vendors. Testing campaigns are a mine of information for gaining knowledge on the solvent performances, benefits and drawbacks.

Each owner has two persons involved in TCM’s technical committee. – The continuous exchanges between the comittee and TCM is a way to address all the technical and scientific challenges related to the vendors activities. I would also say that TCM is attentive to the owner problematic and expectations. Internal workshops are organized to synthesize results of campaigns and share knowledge on specific topics.

A new business model is needed for TCM

When asking if there will be need for the business TCM runs also in the future, the answer from TotalEnergies is a conditional yes.

– Following the deployment of several large-scale PCC plant, new problematics should appear. There will be a need for both technical assistances, for which TCM experienced people could play a role, qualifying equipment and developing new equipment.

The question is in accordance with TotalEnergies opened about the pertinency of the scale of TCM for tackling these issues.

– The cost for running the amine plant is quite high. A new business model is needed so as to continue to use it and to gain knowledge on the remaining gaps in solvent-based post combustion CO2 capture: solvent management, emissions, operational issues, dispatchable operations, heat integration, high level CO2 capture processes.

– For the 3rd site, it seems possible to continue as it is. Such site is mandatory to test and evaluate all the emerging technologies in areas on which the future of PCC (Procurement, Construction, Commissioning), is still uncertain, says Anne Brisset.

TCM has been the catalyst for collaboration on CCS

– The powerful, close, and fruitful collaboration between the owners of TCM has developed companies within carbon capture and storage more than we could have managed each for ourselves.

The collaboration on TCM has also been a catalyst for even more CCS collaboration among the owners, not least the important storage project Northern Lights.

This is what Stig Harald Soligard, Asset Manager at Equinor and member of the company meeting (board) of Technology Center Mongstad DA (TCM), says. Equinor has been a co-owner of TCM since the company was founded and has also had operational responsibility for the test center.

– We have worked with CCS since the early 1990s. But since the start-up of TCM in 2012, most of our knowledge in this field has come as a result of TCM’s activities. A lot of knowledge and lots of discussions has been brought back – to the understanding and development of the knowledge we now have in Equinor, he says.

Has had confidence in CCS

This has not come for free. – I would say that despite a lot of resistance and skepticism to CCS in the world, we who are behind TCM have maintained a confidence that it will sooner or later be realised. That is why we have all invested so much in the project. We are now seeing results in that a functional supplier market for technologies has been developed and is ready for commercial use. The efforts made by TCM’s organization and owners can thus benefit both Norway and the rest of the world.

In this context, Soligard says that it is obviously of great value that TCM has taken a leading role in terms of routines and control of emissions of amines and nitrosamines in the capture of CO2, based on Norway’s strict environmental legislation. – TCM has developed excellent knowledge in this important area and made it available to players and authorities in other countries. In addition, TCM has been very good at disseminating results and knowledge from the open test campaigns to both industry, research environments and the public.

With TCM, theory has become a reality

The partnership agreement between the owners describes five goals for TCM’s business, with the reduction of costs and risk of distributing CCS as the first. – TCM has undoubtedly contributed to significant risk reductions in both engineering, construction, and operation of capture facilities. Today we know the business – before TCM, we only knew the theory. Awareness and reduction of these risks can now be transferred to real projects and have a real significance for the establishment of full-scale capture facilities, Soligard emphasizes.

– Then we must be honest that in terms of costs we cannot be as happy. We can see a total cost reduction in the range of 20 – 30 percent for a traditional amine capture plant. This technology has an inherent weakness in terms of footprint and construction costs. However, TCM has shown that variations in solvents can affect operating costs, both in terms of solvent efficiency, degradation, electricity and steam consumption, and emissions to air. I would also like to point out that new technologies that are now being tested on the Site for Emerging Technologies have the potential to realize the construction of more compact facilities, and thus also a reduction in actual construction costs.

Stig Harald Soligard represents Equinor on the board of TCM. – Despite too much resistance and skepticism to CCS around the world, we who are behind TCM have maintained a confidence that it will sooner or later be realized, he says in this interview.

Objectives for distribution and knowledge sharing fulfilled

The goal of facilitating a broad international distribution of CCS technologies, Soligard believes has been met. – Development of this type of technology requires a broad collaboration between national actors, research environments, small companies, and large industrial actors with significant financial and human resources. All this has merged with TCM in an exemplary way. We have believed in the project, “climbed all the mountains”, and shared knowledge and results as much as possible. Technology developers from all over the world have come to Mongstad and, where it has been needed, TCM has contributed to the development of the commercialized technology.

For TCM, it is also a goal to contribute to the development of technology suppliers and subsequent competition. In this connection, Soligard emphasizes that many companies that have tested at Mongstad have not, on their own, had the financial ability to take the last step towards commercial qualification of their technologies and have been able to benefit from subsidies from TCM’s owners. In this way, TCM has been the world’s most important contributor to the independent development of CO2 capture suppliers and to competition in this market.

As a contributor to broad and relevant knowledge sharing about CCS, TCM has also passed the test. Stig Harald Soligard says that TCM has documented a large number of scientific productions and had an active presence in the right external arenas. He also points out that TCM has participated in several EU-funded projects with many partners, all of which have contributed to valuable learning.

Has contributed to important learning in the owner companies

The latest goal for TCM has been to support the owners to become informed buyers and users of CO2 capture technologies. – Both Equinor, Shell and TotalEnergies have extensive R&D expertise within CCS. But the direct knowledge of actual operational learning cannot be underestimated. I think all the owners fully recognize the importance of TCM in bringing our respective companies into a low carbon future. All the owners are now at the forefront of the full-scale ambitions we see becoming a reality, Soligard emphasizes.

Gassnova a competent and valuable partner

He emphasizes that the cooperation between the state and the industry over the years has been crucial for the development and the position the industrial owners has today. – No industrial player could take on the commercial challenges and risks of developing CCS alone. CCS is still not a broad commercial business, and close cooperation will therefore still be necessary. The long collaboration with the state has clearly educated both sides to see the challenges and benefits of working together. In this context, we recognize how Gassnova has developed into a very competent and valuable partner.

Can become an arena for the development of new technologies

In Equinor, it is believed that it in the future there will also be a need for the business TCM runs, under some conditions:

– TCM must be able to continuously restructure the business to serve changing requirements and needs in the market. For our part, we believe that traditional amine technology has matured, and that it is only possible to achieve marginal improvements. We are open to new technologies, but TCM may be too large and too expensive for the development of these. On the other hand, we will be able to assess whether TCM can be an arena for technology qualification for hydrogen, ammonia, biofuels and new low-carbon technologies. The possibilities are many, concludes Stig Harald Soligard in Equinor.

Great celebration of TCM’s 10-year anniversary

TCM’s 10-year anniversary became a great celebration on Friday 6 May, first with lunch for invited guests in the canteen at Mongstad and then with an anniversary dinner for all employees and guests at Kilstraumen Brygge.

– TCM has laid the foundation for the largest investment in Norway in recent times, said CEO Muhammad Ismail Shah.

During the lunch, the jubilee received greetings and kind words from Secretary General Andreas Eriksen in the Ministry of Petroleum and Energy, who through Gassnova is the majority owner of TCM, and from the mayor of Alver, Sara Sekkingstad. The Chairman of the Company Meeting (Board) of TCM, Svein Ingar Semb from Gassnova, also expressed great appreciation for everything TCM has conducted and achieved since the opening of the facility in 2012. So did representatives from the industrial owners, Equinor, Shell, TotalEnergies, the managing director for the Northern Lights, Børre Jacobsen, and Baste Tveito, who is the general manager of Nordhordland Næringslag.

At the end of the lunch event, CEO Muhammad Ismail Shah gave a speech to the guests.

Have a lot to thank Norway for

I was hired as CEO of TCM three months ago. I am 41 years old, married, have four children and live in Alversund – a half hour drive from Mongstad. We moved here in 2016 – at the same time as I started at TCM. Both my family and I thrive living here. For the last two years before I got the job as the company’s CEO, I was working as technology manager at TCM. The working days are often long and challenging, but they are very rewarding and meaningful.

The reason I came to TCM was that in 2011 I was recruited in Gassnova as a technology advisor. Then I had worked for three years in a company in Eastern Norway with projects converting biomass to transportation fuel. The basic for that recruitment was a bachelor’s degree in chemical engineering from the University of Engineering & Technology Peshawar in my native Pakistan, and then a master’s degree in oil and gas engineering from the University of Aalborg, Denmark.

My great wish is that I, together with my skilled colleagues, our good owners, customers, and partners, will continue to work with the development of technology which I am convinced will make a significant difference in the fight to achieve the climate goals.

The climate threat is dramatic

That the climate threat is dramatic was reported last week from India in the media worldwide. The world’s soon most populous country is now hit by a heat wave with temperatures soaring to 50 degrees Celsius. The heat has led to reduced wheat yields and concerns about how the country will be able to meet its own needs, and at the same time fulfil its ambition to export more.

That the temperature is constantly rising and has noticeable consequences, I have also been able to ascertain on holiday trips for the family back home in Pakistan. There is a real urgency to come up with measures that can save the livelihoods of people around the globe.

The climate threat is also very real in our part of the world, and awareness of our responsibility to contribute to solutions is strong. Ahead of the TCM anniversary, we have on our website interviewed Oscar Graff, who for a lifetime has been at the forefront of Aker’s investment in technology for carbon capture. He says:

«For me, it is basically about being able to go to the grave in the knowledge that there is both hope and possible to save our common planet. The UN’s latest climate report is frightening reading. The climate challenges are gigantic, and both the UN and the IEA leave no doubt that carbon capture and storage, together with the transition to renewable energy, is an absolutely necessary part of the solution. My descendants should know that my generation has also understood the seriousness and done the best we could to develop technology that makes it possible to avoid the world’s biggest environmental disaster.»

Aker has a lot to thank TCM for

Aker has done that, and Oscar Graff says they have a lot to thank TCM for. Aker built our amine plant and was the first to test its technology at the plant in 2013 – 2014. That one of the streets out at the plant is called Akersgaten, thus became a matter of course. But when Aker, in collaboration with TCM, launched their campaign, there was great uncertainty as to whether their technology actually worked as assumed after attesting at lab scale with the company’s mobile test unit. However, this was tested and verified here at the plant – under real industrial conditions. The fact that Aker, in competition with several other companies, has been chosen as a technology supplier for CO2 capture at Heidelberg Materials’s cement factory, is thus not only a feather in the hat for Aker – but also for TCM. In 2024, the capture part of the Longship adventure is ready to start.

Longship also includes the carbon capture plant at Klemetsrud in Oslo. Now when Oslo Municipality ensured the financing of the project, capture of CO2 associated with Norway’s largest waste incineration plant could start in 2026. In this project, technology from Shell Cansolv will be used. Shell Cansolv tested in two rounds at TCM in the period 2014 – 2016.

Has laid the foundation for major industrial investment in Norway

In other words, testing and verification of technology at TCM has laid the foundation for the largest industrial investment in Norway in recent times. This we are proud of!

We are also very pleased that our industrial owners, Equinor, Shell and TotalEnergies, have joined forces on the transport and storage part of the Longship project, Northern Lights. In this way, TCM has been a catalyst for collaboration on the development of a Norwegian CCS industry between large and reputable companies, all of whom are investing significantly in playing a role in the green shift globally.

We are also very proud of the work we have done to facilitate the testing of emerging technologies for carbon capture, technologies that can be used to capture CO2 from different industrial plants and sizes. Recently, two research-based companies from the US, MTR and TDA Research, completed their tests on our Site for emerging technologies with technology based on membranes – both founded by the US government. Several others are knocking on our door for testing.

In summary, testing and verification of technology at TCM has proved instrumental in bringing forward technologies for industrial applications to cut CO2 emissions. In addition to the projects included in Longship, several other technologies have been developed through TCM, and are being delivered to industry elsewhere in the world.

Much has been done – and much remains to be done

Then one can ask: Has TCM done its job? Has the development of technologies for CO2 capture after ten years of operation come so far that we can just as well pack together – hoping that those who will supply technology to the industry and the companies that will make use of it, can now manage completely on their own?

My answer is no. TCM has managed to mature and reduce risks in first and second generations technologies, which are ready to be used today, but we are not done. The cost of CO2 capture must go down! This is done by continuous innovation, development, testing and verification. Therefore, there is still need for TCM, to reduce costs for technology, and for technology for different industries come into place.

The current operation period for TCM expires at the end of 2023 – and we believe it must be followed up with a new agreement among the partners. We are convinced that those who are now in the process of realizing full-scale CO2 capture based on amine technology, both in Norway, in the UK and a number of other places in the world, and the many who plan such projects, will still need to test and verify their technologies. They will also need assistance in training personnel to operate the facilities, and in troubleshooting. Where else in the world should they find test facilities and competence they need other than at TCM?

TCM needs greater predictability

I mentioned new capture technologies, and the demand we are experiencing in the market for testing and verification is constantly increasing. When technology suppliers in the US take the significant extra costs involved in moving personnel and equipment to Mongstad, it is because we guarantee a quality of the campaigns thy do not get elsewhere. It is the test results that count, before commercialization of the technology you have developed.

But then it is also the case that it normally will take one – two years from the time an agreement is entered into until the campaign can be implemented. This is because both we and the technology suppliers need the time to ensure good quality as desired and expected.

Then it can be argued that there are limits to how long and how much our owners, and then primarily the Norwegian state, will subsidize the operation of the fantastic test facilities having been built up at TCM. Of course I understand that. However, then you should remember that while in the first years after the start-up in 2012 we received about 400 million kroner annually from the state budget, this amount in the current year is just under 170 million kroner. In other words, we have both managed to increase the external financing for operations significantly and to increase the level of activity year by year by giving customers more opportunities and offers – at the same time as the staff has been reduced. The experience we have gained means that we work far more efficiently and at a significantly lower cost.

What we are asking for is thus not primarily more money, but greater predictability. An operation period of three years in a row is too short to be able to enter into binding agreements with companies that want to use our services – we need a guarantee for the operation of TCM for at least five-six years ahead. It will also contribute to more stability in the organization of about 60 employees, which has been and still is a challenge.

Should become an arena for green technology qualification

Norway has, thanks in large part to TCM, taken the lead when it comes to making CCS an industry. Theory has been translated into reality. Our test facilities are still the best in the world. The predictions that after a few years the TCM would become a ghost facility have been put to shame. It shows the list of a total of 17 test campaigns that have been conducted here since 2012.

But if we look ahead, what we have jointly created also has a significant potential as an «engine» for other parts of the green shift. My opinion is that TCM can also be an arena for technology qualification for blue hydrogen, hydrogen turbines, chemicals from CO2 and hydrogen, biofuels and new low-carbon technologies. Why build completely new institutions and facilities for testing new technologies, when we have already invested billions in this facility and built a competence and brand that is recognized worldwide? We have the physical space at our disposal – and we have very valuable human resources for work at the interface between research and industry as a basis for developing solutions the world needs. Technology Centre Mongstad is catching our future!

The United Nations prayer

I started by saying a few words about myself, and the opportunity I have been given as the leader of this fascinating and wonderful business. Now it’s about taking TCM into a new era, a task that, among other things, requires a good understanding of technology, the ability to collaborate and a lot of youthful courage. The team I lead is extremely good – and we are optimistic about our opportunities in the future.

Planet Earth is just a star in space.

It is our duty to turn into a planet where all living things no longer have suffer from war, hunger and fear, and are no longer completely unreasonably divided by race, color and ideology.

Give us the courage and strength to begin this task today, so that our children and children’s children one day bear the name: Man – with pride!

Thank you for your attention!

Secretary General Andreas Eriksen in the Ministry of Petroleum and Energy, Some of our guests, Muhammed Ismail Shah, Managing director TCM. The Chairman of the Company Meeting (Board) of TCM, Svein Ingar Semb from Gassnova and Roy Vardheim, CEO Gassnova.

TCM should continue to play a role for the CCS industry

– We see TCM continuing to play a critical role as a world leading authority in testing CO2 capture technologies. TCM is and will continue to be uniquely positioned to enable the commercialization of advanced and cheaper CO2 capture technology solutions, thanks to its state-of-the art facilities, and the deep expertise and passion of its people.

This says Nina Thowsen, Asset Manager in Shell Norway, and member of the Company Meeting (the Board) of Technology Centre Mongstad DA (TCM). Shell has been one of the owners of TCM since the first Participants Agreement was entered into in 2009. Through Gassnova, the Norwegian state has a 73.9% ownership interest. The industrial partners, Equinor, Shell and TotalEnergies, all have an 8.7% stake in TCM.

The objectives have been successfully worked and obtained

The Participants Agreement describes the following objectives for TCM:

- Reduce cost and risk related to deployment of CCS

- Facilitate wide international deployment of CCS technologies

- Contribute to development of technology vendors and subsequent competition

- Contribute to wide knowledge sharing where relevant for CCS

- Support the Participants to become informed buyers and users of CO2 capture technologies

– When looking back at 10 years of operations at TCM, our assessment is that these objectives have been successfully worked and obtained. TCM has become a renowned facility and brand, through neutral facilitation of technology development. It’s been a great journey and as the momentum for CCUS (Carbon Capture, Utilization and Storage) grows stronger, we hope to see TCM further strengthen its position.

Nina Thowsen represents Shell in the Board of TCM. - TCM is and will continue to be uniquely positioned to enable the commercialization of advanced and cheaper CO2 capture technology solutions, she says.

TCM has completed Shell’s global CCS strategy

When asking in what way the collaboration on the owner’s side has enriched Shell’s understanding of and development of CCS technology, Nina Thowsen says it has complemented the company’s global CCS strategy in two ways. – Both by supporting our efforts to drive CCS towards commercial viability through governmental and industry collaboration, and by acquiring relevant know-how and accelerating capture technology development with the lowest net cost to facilitate potential future CCS and CO2 EOR (Enhanced Oil Recovery) projects.

– As such Shell has been both a partner and a customer to TCM, Thowsen continues. – The Quest CCS facility in Alberta, Canada – operated by Shell and being one of the world’s largest CCS facilities in commercial scale – uses carbon capture technology from a group of technologies tested at Technology Centre Mongstad. Several Shell employees have also been seconded into TCM, to both contribute with expertise and to learn.

TCM has contributed to important progress

Nina Thowsen emphasizes that TCM since start up in 2012 has contributed to important progress in the CCS space by delivering technology testing and qualification, and advisory services to a wide range of customers globally.

– Furthermore, TCM has played a central role in developing the technology further and reducing the cost of carbon capture – which dominates the value chain costs for post-combustion capture, and which represents a significant hurdle to the commerciality of CCS for industry.

Thanks to the Norwegian state and the industrial partners

Shell recognises the leadership shown by the Norwegian government to prioritise CCS development and deployment.

– We believe the progress of CCS development and deployment would have been far less if the state had not taken the major role that it has done. We also appreciate the cooperation we’ve had with Gassnova and our industry partners Equinor and TotalEnergies in TCM, says Nina Thowsen.

Looking back on 10 successful years

– The development of technologies for capturing CO2 would definitely not have reached as far as we have come without the test facilities and expertise of TCM. The company’s future is determined by what the technology suppliers and the industry in general will demand from services.

This is what Svein Ingar Semb, Chairman of the Company Meeting (Board) in Technology Centre Mongstad DA (TCM), says. Gassnova is the Norwegian state’s company for CCS, and has an ownership share of 73.9 percent in TCM. The industrial partners, Equinor, Shell and TotalEnerigies, each own 8.7 percent. The collaboration is based on a partnership agreement that is valid until the end of 2023.

– The Government’s and Gassnova’s starting point is that when several full-scale facilities for capturing CO2 gradually come into operation, the competence of TCM will be relevant both for problem solving along the way, and for testing that can make the capture processes even more efficient. We also register great interest in testing completely new technologies on TCM’s Site for Emerging Technologies. In other words, technological development does not stop.

Has given unique results

Through the establishment of TCM, the state took significant financial responsibility for facilitating testing and verification of capture technologies, as part of an overall strategy to achieve the climate goals nationally and globally.

– The utility value for our own country we now see, not least through the realization of the Longship project. Aker was responsible for the construction of the amine plant at TCM. They then tested the technology that was later chosen for capturing CO2 at Heidelberg Materials’s cement factory in Brevik. In this way, they verified that the technology is safe and will work in a full-scale capture facility. The same applies to a number of internationally renowned technology suppliers who are now in the market with their solutions.

– We can also measure utility value through the scientific work TCM has contributed to the CCS industry, in collaboration with institutions such as SINTEF and a number of universities at home and abroad. This is documented in close to 50 articles published in reputable journals shared on many platforms, which has given the industry a large supply of knowledge. By sharing the results of the TCM open test campaigns, the industry has also received a useful benchmark for the development and improvement of its proprietary technologies. This knowledge also simplifies the work and reduces the costs for project owners for future capture facilities.

Svein Ingar Semb chairs the Company Meeting (Board) of TCM in the anniversary year. (Photo: Gassnova).

Dedicated employees are the most important factor in our success

Svein Ingar Semb emphasizes that the good results after ten years of operation have by no means been a matter of course. – One thing is to finance and build the world’s largest and most flexible facility for testing capture technologies. However, success is first and foremost a result of human ability and willingness to innovate, solve problems, and to create progress and results. I am impressed with the focus and efforts of the team at TCM.

Fellowship with the industry has been crucial

According to Semb, the collaboration with the industrial partners has been absolutely crucial for TCM. – Equinor took an operational responsibility for TCM from the very beginning, and their personnel have done an outstanding job. Like Equinor, Shell has been involved all the way, and both have added important knowledge to the environment. This also applied to South African Sasol, which was a co-owner until 2017, and TotalEnergies, which has since replaced them. I would say that the ownership community has been and is the «engine» in TCM and works very well.

Has opened doors internationally

– That the industrial owners have also received a lot in return by taking responsibility for the operation and development of TCM, has been the intention, Semb maintains. – They are all investing significantly to take part in the green transition.

Svein Ingar Semb believes that the ownership community with heavy industrial players has also been of great importance for the reception and interest TCM has been met with internationally, and first and foremost in the USA. The collaboration result from a bilateral MoU (Memorandum of Understanding) from 2009 between the US and Norwegian authorities on energy research, where CCS is highlighted as an area for joint efforts.

– TCM has thus been a catalyst, where technology suppliers and research-based institutions, with financial support from the Department of Energy, have come to test and verify technologies. This has been very fruitful for both parties. In June, a large delegation from the United States will come to TCM to summarize experiences. We are registering great American interest in testing at the Site for Emerging Technologies, where both TDA Research and Membrane Technology Research (MTR) have already conducted successful campaigns.

Looking forward to the continuation

– When we look back on TCM’s history on this anniversary, we should be proud that TCM has shown its legitimacy as the world’s largest and most flexible test facility, with competent employees who both take care of the operation of the facility and engage in knowledge sharing of the highest class. I am proud of what we have achieved and look forward to following the CCS development in the time to come, Svein Ingar Semb concludes.

Test campaigns at TCM 2012 – 2022

2013 – 2014: Aker Clean Carbon (Norway)

Aker Clean Carbon, now Aker Carbon Capture, was the supplier of the amine plant at TCM, and performed testing of its capture technology. The implementation of this test resulted in valuable experience for later test campaigns at TCM. Aker Carbon Capture is the supplier of the technology chosen for capture in the planned full-scale project at Heidelberg Materials’s cement factory in Brevik.

2013 – 2014: Alstom (France)

With technical assistance from TCM, Alstom carried out the first and so far only test to date at the ammonia plant, with CO2 capture based on the Chilled Ammonia Process (CAP) technology. Baker Hughes and TCM are considering reopening the ammonia unit and conducting tests.

2014: The owners of TCM and Aker Clean Carbon

The first open access, research-based test campaign at TCM on the amine plant with the carbon capture liquid MEA (Mono Ethanol Amine), initiated and financed by the owner companies in collaboration with Aker Clean Carbon.

2014 – 2015 and 2016: Cansolv Technologies Inc (Canada)

Cansolv conducted two separate campaigns to test their technology in the amine plant. The aim was to verify the technology for use in a CO2 captureproject in the UK. Cansolv, in collaboration with Shell, has further developed this technology. The capture technology was chosen for Fortum Varme’s planned full-scale project at Klemetsrud in Oslo.

2015: The owners of TCM

Based on results from the first open test with the carbon capture liquid MEA in 2014, a new test was carried out which gave significantly improved results in terms of capture rate and energy consumption in the amine process.

2015 – 2016: Carbon Clean Solutions (UK / India)

Carbon Clean Solutions carried out tests of its capture technology at the amine plant as part of the preparations for the company and partners to start full-scale capture and storage related to chemical processing in Chennai, India.

2016 – 2017: ION Engineering (US)

With support from The US Department of Energy (DoE), ION Engineering (now ION Clean Energy) conducted a test campaign at the amine plant of the company’s proprietary carbon capture solvent. Based on the results, ION has further developed its technology.

2017: The owners of TCM

The third research based MEA test was conducted in 2017. Among the research topics was reduction of contaminant levels in the treated gas leaving the process. In the tests with this carbon capture liquid at TCM, it has been possible to capture up to 98 % of CO2 with aqueous MEA (a mixture of water and MEA).

2017: TCM, SINTEF, NTNU and Cybernetica (Norway)

With support from the Norwegian state through CLIMIT, the partners jointly carried out experiments on the amine unit and in laboratories, with the aim to improve efficiency and operational stability of the process. This, and other open test campaigns at TCM, have given new insight into important advancements in generic capture technology.

2017 – 2018: The owners of TCM and SINTEF

With support from the Norwegian state through the CLIMIT-project Aerosolve, a test was carried out to identify aerosol-based mechanisms to reduce emissions when processing post combustion industrial flue gases e.g from refineries and cement plants in connection with CO2 capture, and to take countermeasures to verify that the performance is within the environmental limits given in the emission permit. The knowledge of how to develop and operate CO2 capture facilities within given emission permits was strengthened.

2019: Fluor Corporation (US)

With support from The US Department of Energy (DoE), Fluor conducted a test campaign with their proprietary carbon capture technology.

2019-2020: ALIGN-CCUS

ALIGN-CCUS (Accelerating Low Carbon Industrial Growth through Carbon Capture Utilisation and Storage) was a project financed through the first ERA-NET Co-fund ACT program, funded by nine European countries and the European Union Horizon 2020 program. TCM was one of the test sites that demonstrated the use of the non-proprietary capture liquid CESAR1 on large scale with real industrial flue gas.

2020: The owners of TCM

The owners of TCM jointly carried out a test with the research-based capture liquid CESAR 1 aiming at capturing CO2 at the lowest possible cost. The test was initiated by the IEA, which through its «Greenhouse Gas R&D Program» has requested a comprehensive assessment of new technologies for capturing CO2 in the energy sector. In the final phase, tests were performed for SSE Thermal (UK and Ireland) and Imperial College London on dispatchable operation of carbon capture facilities.

2021: Mitsubishi Heavy Industries Engineering (Japan)

Mitsubishi Heavy Industries Engineering (MHI) tested its technology at the amine plant during the summer 2021. This included high CO2 capture rate testing and qualification of MHI’s latest solvent on both flue gas types available at TCM.

2021 – 2022: TDA Research (US)

As the first user of TCM’s new Site for Emerging Technologies, TDA Research conducted experiments with a hybrid technology utilizing both a membrane-based and a sorbent-based capture step. This test campaign, funded by the US Department of Energy, aimed to demonstrate TDA’s technology on real flue gas with a view to applying their modular design to applications such as carbon capture from coal power generation.

2021 – 2022: Membrane Technology and Research (US)

Membrane Technology and Research (MTR)has used the Site for Emerging Technologies to conduct experiments with membranes. MTR’s tests of their multi-stage membrane system using their Polaris Gen 2 membranes were funded by the US Department of Energy and allowed MTR to test the performance of their system, including a low pressure-drop membrane module design, on real flue gas.

2022: Research Foundation RTI International (US)

The research foundation RTI International conducts a test of a new non-aqueous solvent at the amine plant. The US Department of Energy (DoE) covers amine plant modification and test costs. The modifications include the installation of an intercooler system on the TCM absorber to improve the energy performance of the capture system.

RTI is testing at TCM: So far, so good!

– The main objective for RTI International is to find a cost-effective technology for capturing and storing CO2 emitted from fossil fuel power plants. We started the test campaign at TCM with our water-lean solvent in the beginning of March, and so far the results are matching closely to the goals.

Marty Lail (49), Senior Director of Carbon Capture and Conversion at RTI International, is smiling. He has been working in the field of carbon capture for fifteen years, the last twelve of them in one of the largest non profit science foundations in the United States. For him and his colleagues, the ongoing test campaign at the amine plant at Mongstad will provide significant answers to whether many years of intensive work have been good enough to offer the market a groundbreaking technology for capturing CO2. So far, so good!

The last stop on a long journey

Research Triangle Institute (RTI) has its headquarter in North Carolina, and around 6.000 employees in 75 countries. Carbon capture and storage (CCS) is one of several focus areas. – We have developed a water-lean solvent that can absorb carbon dioxide before it reaches the atmosphere. Before we came to Mongstad, we tested the technology in our lab in Research Triangle Park, North Carolina and at SINTEF’s Tiller pilot plant facility in Trondheim.

The test at TCM under almost full scale is the last stop on a long journey to be able to commercialize their research efforts. – Therefore, we are incredibly excited about what we can document when six months of at least 1.000 hours of operation here at Mongstad are over. The solvent will be tested with both flue gases from the refinery at Mongstad, containing from 4 percent and up to 13 percent CO2. This is important to demonstrate that the solvent is useful for different industrial purposes, says Lail.

Costs have fallen significantly

According to RTI International, conventional carbon capture technologies have been unable to economically address the CO2 emissions generated by large, stationary point sources. Their CCS team is exploring CO2 capture and utilization technologies that could dramatically impact the fossil fuel-based power production and industrial sectors. For example, RTI’s non-aqueous solvent for carbon capture, eCO2SolTM, substantially reduces the specific reboiler duty (SRD) by 30 – 50 percent compared to state-of-the-art approaches.

Marty Lail tells that steady progress over the years has enabled RTI to bring the cost of carbon capture down significantly, from almost 100 USD per ton to 42 USD per ton. – Our success, as well as the successes of others in the CO2 capture communtity, has prompted our client, the US Department of Energy, to lower the target price for carbon capture to 30 USD per ton by 2035, at which it would become much more attractive to industry and keep the overall increase in cost of electricity to consumers affordable.

The US Department of Energy (DoE) Fossil Energy and Carbon Management has provided the funding for amine plant modifications and other testing costs. To document lower energy consumption, and thereby less cost of the process, is not the only target of the test campaign at TCM. – It is also very important to demonstrate the endurance of our solvent; that it works continously in one operation for at least 1.000 hours during the test period of six months. Then we also should verify that the emissions from the process are within TCM’s permission and competitive with other amine-based technologies.

Marty Lail (right) together with TCM’s coordinator for the campaign, Anette Beate Nesse Knarvik, in front of the test facility at Mongstad.

Demanding to organize and prepare

The pandemic made organizing and preparing for RTI’s test campaign particulary demanding. To conduct the test, modifications at the amine-plant were needed. They were planned by RTI and designed by TCM and the Norwegian engineering company Pressura last autumn. Several local subcontractors contributed to the work, which went very well according to Lail. The modifications include the installation of an intercooler system on the TCM absorber to improve the energy performance of the capture system and a larger circulation pump on the TCM desorber.

Another challenge was to transport 75 tonnes of RTI’s solvent, which is produced at a factory in Germany, to Mongstad. Despite the potential pitfalls, the campaign started only two weeks late. It is continuously followed by Marty Lail and three colleagues, Vijay Gupta, Jak Tanthana and Paul Mobley, in a shift arrangement with two weeks at Mongstad and six weeks at home.

Grateful to the staff at TCM

– This is an outside-the-box campaign, and I like to thank everyone involved – and in particular the staff at TCM – for their efforts which have made it possible, Lail emphasizes. – We knew that the facilities at Mongstad are world class, but we also found the personnel top shelf. For RTI, it is extremely important that the secrets we share with selected employees remain with them. We have no reason to doubt their integrity, he adds.

Visits from commercial partners

Although RTI is a non-profit organization, they have a clear ambition to license the capture technology and sell it to technology suppliers. – We are already in contact with commercial partners, who will also have the opportunity to visit Mongstad while the test campaign is in progress. This makes the project extra exciting, says Marty Lail.

– We started the test campaign at TCM with our water-lean solvent in the beginning of March, and so far the results are matching closely to the goals, says Marty Lail.