The Potatoes at TCM

They are two of the wheels that keep administration and operations at Technology Centre Mongstad (TCM) running smoothly. Gøril Nyhammer-Haugen and Jorun Hovda each play an important role in the organization, but their tasks often overlap in daily work.

Like potatoes – they can be used for almost anything, and that’s precisely what makes them indispensable.

For Gøril, the desire for new challenges led her to TCM. After 15 years at the same workplace, she was ready for a change. A job listing caught her attention, and by the summer of 2024, she had joined TCM as an Office Administrator.

Jorun, on the other hand, has been with TCM much longer. She started in 2013 as a hired consultant and has been permanently employed as a Project Controller since January 1, 2024. “My workdays are varied and fun,” she says, emphasizing how great it has been to have Gøril join the team.

Gøril (left) and Jorun always start the day with a little pep talk — a routine that sets the tone for the rest of the workday.

Daily Life at TCM

A typical day for Gøril consists of a range of administrative tasks. She coordinates visits, orders refreshments for meetings, sends agreements for signing, creates Teams channels, monitors shared inboxes, and even waters the plants. “I’m a little bit everywhere,” she says with a laugh.

Jorun, for her part, works with cost tracking, monthly reporting, financial follow-up of projects, budgeting, and procurement-related tasks, but the two work closely together on a daily basis. They always start the day with a little pep talk – a routine that sets the tone for the rest of the workday.

Exciting Experiences

Both appreciate the international environment at TCM, even though it sometimes presents language challenges. Gøril admits she was nervous about speaking English again after many years but has found her own solution: “I prefer to speak Norwegian, and several colleagues are learning the language along with me!”

Among the most memorable experiences, Jorun highlights Crown Prince Haakon’s visit to Mongstad in March last year. “I served him coffee with both hands – just to make sure I didn’t spill,” she says with a smile. “It was a big day with a lot of preparation, but everything went smoothly.”

Name: Jorun Iren Hovda (47)

Marital status: Has a partner, three children, and three grandchildren

From: Austrheim

Job: Project Controller

Education: Two-year degree in Economics and Administration from Sogn og Fjordane University College

Work experience: Customer service representative at Sparebanken Vest, Financial Consultant in the former Lindås municipality, Consultant at a local shipping company in Austrheim. Control Coordinator at TCM 2013–2024, and Project Controller 2024–present.

Good at: Teamwork

Dislikes: Ingratitude

Hobbies: Handicrafts, working out, hiking

Dreams of: Living in my own little château in France 😊

CO2 Capture and the Core Mission

As administrative staff, they are not directly involved in technology testing, but both see the value of TCM’s work. “Carbon capture is an important part of the solution to climate change,” says Gøril. “Even if I don’t understand all the technical details, I know we are contributing to a better future.”

Jorun agrees. She finds that many in the local community are familiar with the facility and its activities, often referring to it as the so-called “moon landing.” “I often have to explain that we have actually helped develop technologies that are now being used at full scale for CO2 capture.”

Job Satisfaction and Frustrations

What gives them the most energy at work? For Gøril, it’s about getting things done. “When I can check tasks off my list, I’m satisfied. And, of course, my colleagues!”

Jorun appreciates the well-established routinesthat ensure everything runs smoothly. At the same time, she finds it frustrating when complex regulations make processes unnecessarily cumbersome.

Name: Gøril Marie Nyhammer-Haugen (48)

Marital status: Married, two children, and one grandchild

From: Originally from Alversund in Alver municipality, now living in Eidsnes

Job: Office Administrator

Education: Vocational diploma in Office and Administration.

Work experience: Worked in healthcare and social services in former Lindås municipality from 1999 to 2004. Production assistant and personnel officer at WesternGeco from 2006 to 2009. Office assistant at Mongstadbase, harbor and logistics, from 2009 to 2015, and accounting assistant at the same place from 2015 to 2024. Office Administrator at TCM from June 2024 – present.

Good at: Seeing others, being attentive

Cannot stand: People being treated poorly, injustice

Hobbies: Skiing, hiking, working out

Dreams of: A long life with good health 😊

Flowers for Good Colleagues

If they were to give a flower to a colleague, the choice would be easy. Gøril would give hers to Jorun: “She is always positive, helps me with everything, and has answers to most questions. Everyone should have a Jorun!”

Jorun, in turn, would give flowers to Sara in the cafeteria and Linda, who handles cleaning. “They do a fantastic job in making this place a pleasant environment.”

Recharging the Batteries

To unwind after busy workdays, both turn to nature. Gøril loves going for walks, preferably with an audiobook in her ears. Jorun does much of the same. Both have recently become grandparents and thoroughly enjoy spending time with the little ones.

Dreams and Future Plans

Gøril dreams of traveling more. “Italy, France, the Alps – I want to experience new places,” she says. And, of course, she looks forward to spending time with her grandchild.

Jorun also has the travel bug. “This year, we are planning a trip to Northern Norway. But I wouldn’t say no to a getaway to warmer climates either,” she adds with a smile.

Together, they aim to keep the wheels turning at TCM. They are flexible, solution-oriented, and always ready to step up – and they can take on just about anything, just like the potato.

Kathrine makes TCM’s shift plans work!

– Staffing is like a jigsaw puzzle that needs to be put together again and again. It’s both challenging and rewarding, says Kathrine Sætre.

Kathrine joined TCM in 2024 as Team Leader Operation and Maint, bringing with her a wealth of experience from the oil and gas industry. The 44-year-old thrives in a fast-paced environment where close collaboration is key and expectations for the results of CO2 capture tests are high.

Kathrine Sætre has broad experience from the oil and gas industry. Last year, she started in the position of Team Leader Operation and Maint at TCM. “More people need to gain insight into the important work being done here, and how much it means in the fight against climate change,” she says in this interview.

“How did you become part of the TCM team?”

“I participated in Equinor’s leadership development program for first-line managers, where I was challenged to apply for the shift leader position at TCM. It was an exciting opportunity, so I jumped at the chance!”

“What did you know about TCM before you started?”

“I knew that Equinor had a strong focus on CO2 reduction and the green shift, but I didn’t know much about what TCM was doing, other than that they worked with carbon capture technology. Now that I’m here, I find it incredibly rewarding to be part of something so important, concrete, and forward-looking.”

“What is the most exciting part of your job, Kathrine?”

“I enjoy taking responsibility for planning across departments and contributing to collaboration in a compact, competent organization. Staffing is like a puzzle that must be put together again and again, and it’s both challenging and interesting. When we run campaigns with customers testing new technology, it’s especially exciting to see how the operations team solves complex test matrices.”

“What does a typical workday look like for you?”

“The day starts with a conversation with the control room about the night’s operations and any challenges. Then, we have a morning meeting with the various departments. The rest of the day is spent on a lot of collaboration, risk assessments, planning, and execution.”

“How does your education and experience benefit your job?”

“I have vocational certificates as both a process technician and a lab technician, and I’ve worked both offshore and on land. This helps me understand the workday and challenges from the operators’ perspective. Additionally, I’ve been responsible for apprentices, which has given me experience in planning, follow-up, and relationship-building – all of which come in handy as a shift leader.”

“Is there a project you’re particularly proud of?”

“I haven’t been at TCM for very long. The Honeywell campaign, which recently concluded, was my first full test. There were many challenges both before and after the campaign, especially with the solvent. I was really impressed by how skilled everyone here is and how much valuable knowledge they brought from previous campaigns, which helped solve both small and bigger challenges.”

“Who do you work most closely with?”

“I mostly work with shift personnel, leadership, and the technical department. I think we collaborate really well – there are a lot of talented people here, and we achieve a lot together.”

“How do you experience being a woman in a male-dominated work environment?”

“I’ve never really seen it as a problem. I’ve worked with men since I was 18, and I enjoy it. They often think a bit differently than women, and that can be both useful and fun.”

“What brings you the most joy and energy at work?”

“Humor and laughter! And when we solve challenges together as a team and see good ideas come to life.”

Name: Kathrine Sætre (44)

Marital status: Partner, three children

From: Solend in Austrheim municipality

Job: Team Leader Operation and Maint

Education: Vocational certificate as a process technician and lab technician

Work Experience:: Apprentice at Equinor Mongstad; Process operator on Gullfaks C (8 years); Operator at Heimdal; Lab technician on Statfjord A and Veslefrikk; Apprentice supervisor at the Mongstad refinery (2021–2024); Team Leader Operation and Maint (2024 – present)

Good at: Juggling many tasks at once

Dislikes: Saying no

Hobbies: Family, our dog Nala, exercising, hiking, gardening

Dreams of: Her children having a safe and good future; backpacking in South America for three to four months

“What do you think is the biggest challenge in your job?”

“It’s making the staffing puzzle work, especially with a small operations team. If someone is absent, we’re vulnerable.”

“If you could give a flower to a colleague, who would get it?”

“I would give a big flower to those who work 24/7, who are away from their families during weekends and holidays. They were also incredibly patient when I started, sharing their knowledge freely. I’m really grateful for that support.”

“What do your family and friends say about your job?”

“Most don’t know much about TCM, but they think it sounds exciting. Many still mention “the moon landing” – that still lingers! That’s why it’s important to highlight that technology testing at Mongstad has been crucial for realizing the Longship project, with full-scale CO2 capture at the cement plant in Brevik being the first step. The same applies to many other CCS projects around the world. CO2 capture and storage is essential for meeting the goals of the Paris Agreement. More people need to be aware of the important work happening at TCM and how much it means in the fight against climate change.”

“How do you recharge after a long day?”

“After work, it’s all about family, our dog Nala, exercise, hiking, and a bit of gardening. I like to stay active but also enjoy quiet moments.”

“Do you have any dreams for the future?”

“First and foremost, I hope my children will have a safe and good future. For myself, the most important thing is to be able to do a good job and stay healthy. But I also dream of backpacking through South America for three to four months. That would be a once-in-a-lifetime experience!”

Meet Ticiane – A Workaholic with a Mission

Ticiane Silva de Oliveira began her career at TCM conducting data analyses for the MOF4AIR project and is now a CO2 Capture Technologist. At TCM, she is regarded as a true asset—not just for her professional expertise, but also for her relentless drive and passion for her work.

“I know myself well—I get excited when given a new mission. I always want to give my best, exceed expectations, and continuously learn and improve,” Ticiane shares in this interview.

Ticiane Silva de Oliveira: “Many people my age quickly get tired of their job and start looking for something new, but I can’t imagine that happening at TCM.”

“How did you become part of the TCM team?”

“I started working at TCM one day a week in 2023 as a Data Analyst for the MOF4AIR project. From the very beginning, I was impressed by TCM’s efficiency in communication—both internally and externally, which creates such a productive work environment. I remember coming home and spending hours telling my boyfriend how well-organized everything was, how brilliant my colleagues were, and how incredible it felt to work alongside some of the biggest names in the field”

“How was your move from Brazil to Norway?”

“I arrived in Norway just before COVID-19, so you can imagine it wasn’t easy. I questioned my decision many times, but with the borders closed, I didn’t have much of a choice. Being far from my family in those early years was extremely difficult, but at the same time, I felt safe in Norway, which handled the pandemic remarkably well.”

“What surprised you most about Norwegian culture and behavior?”

“What surprised me the most was how Norwegians handle the harsh weather. They go outside no matter what, and when asked, they say, ‘Det finnes ikke dårlig vær, bare dårlige klær’ (There’s no such thing as bad weather, only bad clothing). Their resilience is impressive, and I hope that one day I’ll be able to do the same.”

“What inspired you to work with carbon capture?”

“I have always been passionate about green technologies, but my interest in carbon capture specifically developed after moving to Bergen for my master’s program and working with MOF materials. From there, it didn’t take long for me to learn about TCM and become inspired by the exciting work being done here.”

“How has your education prepared you for your role at TCM?”

“Although my studies weren’t specifically focused on CO2 capture, I have always shaped my career around green chemistry and sustainable alternatives. The biggest influence on my decision to pursue this path was my master’s research project, the incredible people I met along the way, and the fortunate timing of being in the right place at the right time.”

“What is the most exciting aspect of your job at TCM?”

“The most exciting part of my job is its dynamic nature and the constant learning it offers. People of my generation often get bored at work and move on quickly, but I can’t imagine that happening at TCM. Every project brings new challenges, new lessons, and continuous improvement.

Another aspect I love about TCM is its unique combination of an industrial site and a research environment. I have a deep appreciation for both academic work and industrial applications, and at TCM, I get to experience the best of both worlds.”

Name: Ticiane Silva de Oliveira (29)

From: São Paulo, Brazil

Job: CO2 Capture Technologist

Education: Master’s degree, Inorganic Chemistry, from University of Bergen (UiB), Bachelor’s degree, Chemistry, from Universidade de São Paulo (USP), Chemistry Technician, Industrial Chemistry, from Escola Tecnica de Paulinia, Brazil

Work Experience: CO2 Capture Technologist at TCM from December 2024 – present. Part time position at TCM as Data Analyst for the MOF4AIR project from March 2023 to December 2024. Laboratory Manager at Envir from January 2023 – December2024. Scientific Researcher at UiB from August 2020 – August 2022. Industrial Chemist at Solvay, São Paulo in 2018

Good at: Helping people

Cannot stand: Lutefish

Hobbies: Hiking, dancing, socializing, and reading (sci fi and philosophy)

Dreams of: Having a happy, carefree and loud home with my husband, my four beloved kids, our two bunnies, the dog and the chickens.

“Can you share a specific project at TCM that you’re particularly proud of?”

“Absolutely! The MOF4AIR project, funded by Horizon 2020, the European Union’s research and innovation program, stands out for me. During my master’s, I learned that TCM was one of the three demonstration sites for this project. I was eager to understand how the work we were doing in the lab would be scaled up to an industrial level.

I reached out to TCM, arranged a visit, and had the incredible opportunity to receive a VIP tour from Anette Knarvik. The experience was so inspiring that I decided to apply for an internship on this project.

Today, I have learned so much from MOF4AIR. It was a great project to start my journey in CO2 capture. We work hard to achieve the best results for this promising technology while also actively documenting and generating knowledge to support its further development. It makes me proud to collaborate with and learn from experts like Richard Blom, Guy De Weireld, and Shreenath Krishnamurthy—professionals I looked up to during my master’s program.”

“What do your family and friends say about your job?”

“To be honest, most of my friends don’t fully understand what I do. Some even assume I work in oil and gas because of TCM’s proximity to the Equinor refinery. I make a point of explaining the distinction. While post-combustion capture is currently the dominant technology, CO2 capture has a much broader scope, with applications in areas like BECCS and DAC.

I believe it’s important for the general public to better understand CO2 capture for what it truly is—an immediate and crucial solution for the energy transition period, rather than an excuse to continue fossil fuel exploitation.”

“What gives you energy and joy at work?”

“The people, of course! The team at TCM is amazing. We meticulously plan together before each project, collaborate closely during test campaigns, and celebrate every milestone as a team. TCM has the best working environment I have ever been a part of.”

“What do you think is the biggest challenge in your work?”

“Not necessarily as a CO2 capture technologist, but personally, my biggest challenge is being a workaholic.

In my previous job at Envir AS, I was tasked with creating a construction materials testing laboratory from scratch. I love challenges, so I fully committed, dedicating immense time and energy to the project. However, I didn’t realize how much it was consuming me until my boyfriend and colleagues pointed out that I was overworking myself at the expense of my personal life.

I know myself well—I get excited when given a new mission. I always want to give my best, exceed expectations, and continuously learn and improve. My greatest challenge will be maintaining a healthy work-life balance while staying passionate about what I do.”

“If you were to give a colleague a flower, who would it be—and why?”

“As I mentioned, I’m a workaholic, and that trait comes from my parents. They taught my siblings and me to always give our best and strive to be a reference in our field. With that in mind, I’d have to give flowers to two colleagues: Helge Ulvatn and Magnus Aronsson.

Both are true role models at TCM—exceptional at what they do, always willing to share their knowledge, and consistently supporting the team. I truly admire them, and I hope to reach their level one day.”

“What do you value most about your colleagues at TCM?”

“What I value most is their support and how they make my learning process so seamless. There’s no such thing as a silly question, every comment and idea is heard and taken seriously. We truly work as a team, and the horizontal hierarchy at TCM makes collaboration even more effective.”

“How do you recharge after a long day at work?”

“Oh, that’s a tough one! I’m a city girl, so for me, recharging used to mean going out—cinema, parties, dinner with friends, hiking up Fløyen or Ulriken, sunbathing at Gamlehaugen, or swimming in Nordnes.

But in January this year, my boyfriend and I moved to Manger to be closer to Mongstad, and I’ve had to completely rethink how I recharge. Right now, house renovations keep me occupied, but sooner or later, I know I’ll need to find a hobby—otherwise, I might go crazy in this peaceful countryside life!”

“What advice would you give to someone considering a move to Norway or a career in carbon capture?”

“My best advice? It won’t be easy, but don’t give up. Get your dose of vitamin D, find some Latino friends to keep the energy up, and invest in proper rain gear—you’ll need it! And if you happen to find yourself a handsome and romantic French boyfriend, that helps too. Highly recommended!”

Meet Magne Tresvik – a pioneer at TCM

For nearly thirty years, Magne Tresvik has been a key part of the industrial environment at Mongstad. From the early days at the refinery to his role as an Electrical/Instrument Engineer at Technology Centre Mongstad (TCM), he has helped make carbon capture an important part of the climate solution.

In this interview, Magne Tresvik shares memories from the early days of TCM, the biggest challenges, and what keeps him motivated in a rapidly evolving technological field.

Magne Tresvik is a veteran at TCM. “Every test campaign has its own moments of exploration,” he says in this interview.

“How did you become part of the TCM team?”

“I have mostly worked at Mongstad ever since I graduated from NTNU in 1996. I started at the refinery and got to be part of many exciting projects. But when TCM was being planned, several of us were brought in as external engineers to help with the design and realization of the new technology center. When it was completed in 2012, I was offered a job in the company. After a while, I took a short break and worked for Siemens in Bergen for a year before returning to the Modifications Department at TCM. Last year, I was permanently hired, just like most of the other external employees.”

“What do you remember most from the TCM project phase?”

“There were a lot of people working on the facility for Alstom and Aker Solutions, and for those of us involved in electrical installations and instrumentation, the work wasn’t too different from other large technical projects at the refinery.

The most unique thing was probably the pouring of concrete for the absorber at the amine plant. And of course, I remember the grand opening ceremony in May 2012. I was on duty at one of the gates, making sure no unauthorized people got in.”

“What was your knowledge of carbon capture before you started?”

“To be honest, I knew nothing. But the idea of reducing carbon emissions by capturing CO2 fascinated me. At the same time, we have to admit that making it work the right way has been challenging—like any other technological development.

Still, the pioneering work at TCM has delivered results. The carbon capture plant at Heidelberg Materials in Brevik, which is starting operations this year, is just one important example. But there’s still room for improvement, especially in terms of reducing energy costs in the capture process. And there are many exciting new technologies emerging.”

“What’s the most exciting part of your job at TCM?”

“Every test campaign comes with its own moments of excitement. New people from around the world come to Mongstad with different technologies they’re eager to test in real conditions.

In recent years, the testing at Site for Emerging Technologies (SET) has been particularly interesting to be part of.”

“What does a typical workday look like for you?”

“My main job is to ensure good planning, both before and during a test campaign. This includes working with CAD drawings and helping design the equipment needed for the tests.

Right now, we’re wrapping up the Svante campaign at SET. My work with them started with a visit to Canada in April last year, together with Matthew Campbell and Istvan Szabo. That visit helped me understand their approach and what we needed to provide to make their testing at TCM as successful as possible.”

Name: Magne Andreas Tresvik (57)

Marital status: Married, three children

From: Fonnes in Austrheim municipality, lives in Lindås

Position: Electrical/Instrument Engineer

Education: Master’s degree in Technical Cybernetics (Automation) from NTH, now known as Norwegian University of Science and Technology (NTNU). Also holds a vocational certificate as an electrician (Gr. L) and an engineering degree in electrical engineering from Bergen Technical College.

Work experience: Electrical/Instrument Engineer at TCM since 2010. Worked for Siemens in 2013.

Good at: Multitasking

Cannot stand: Dishonest people, smoking

Hobbies: Fishing, hiking, gardening, and dry stone walling

Dreams of: Staying healthy until I turn 100!

“Is there a project at TCM that you are particularly proud of?”

“The establishment of SET in 2021 was a challenge—especially with all the considerations we had to take during the COVID-19 pandemic. But after some back and forth, the modules from two American companies, TDA Research and Membrane Technology and Research (MTR), arrived and were installed.

We were proud that all the work to facilitate testing of membranes or absorbent materials for CO2 capture was successful. That was an important milestone for TCM.”

“Who do you work most closely with, and how is the collaboration?”

“In the MOD group, there are five of us responsible for different tasks, and we help each other daily. We work closely with those in Instrumentation and Maintenance, and we also have a lot of interaction with the Technical Department.

Overall, we have a well-functioning professional collaboration and work environment, and we can bring in external resources when needed.”

What gives you energy and joy at work?

“Sara’s lunch is a daily highlight that gives a lot of energy! 😊

In general, it’s inspiring to see both young and experienced colleagues succeed with technically complex projects. The camaraderie among employees in the company is great and brings a lot of joy.”

“If you could give a flower to a colleague, who would it be – and why?”

“The flower goes to Magnus Aronsson, who works in Instrumentation and Maintenance. He is skilled, solution-oriented, and only asks the necessary questions.”

“What do your family and friends say about your job?”

“When people ask what we do at TCM, I usually say that we work in research. It takes time, it’s difficult, and our facilities are expensive and complex.

We’re still a long way from a perfect CO2 capture solution, but we make small steps forward every day. I think the people around me appreciate that I’m realistic, but at the same time believe that what we do is important for achieving global climate goals.”

“What do you see as the biggest challenge in your work?”

“Planning is everything. The time window for each test campaign is short, so it can become critical if something important is overlooked before starting.

We’re not a big team at TCM, but we have good and efficient routines that leave nothing to chance.”

“Do you have any specific plans for the future?”

“I hope to continue being useful at TCM for many years before retiring.

Other than that, I don’t have big plans—except taking good care of my body and health. Staying in shape, both physically and mentally, is essential for a good life in old age.”

Putta Loves Being an Advisor

Koti, Putta, or Koteswara – a dear child has many names! For the past four years, this highly skilled professional from India has contributed to the development of new ideas for CO2 capture at TCM. However, the role he enjoys the most is within TCM’s Advisory Services.

“Engaging with clients, addressing their questions, and finding innovative solutions keeps the work dynamic and rewarding,” says Koteswara Rao Putta in this interview.

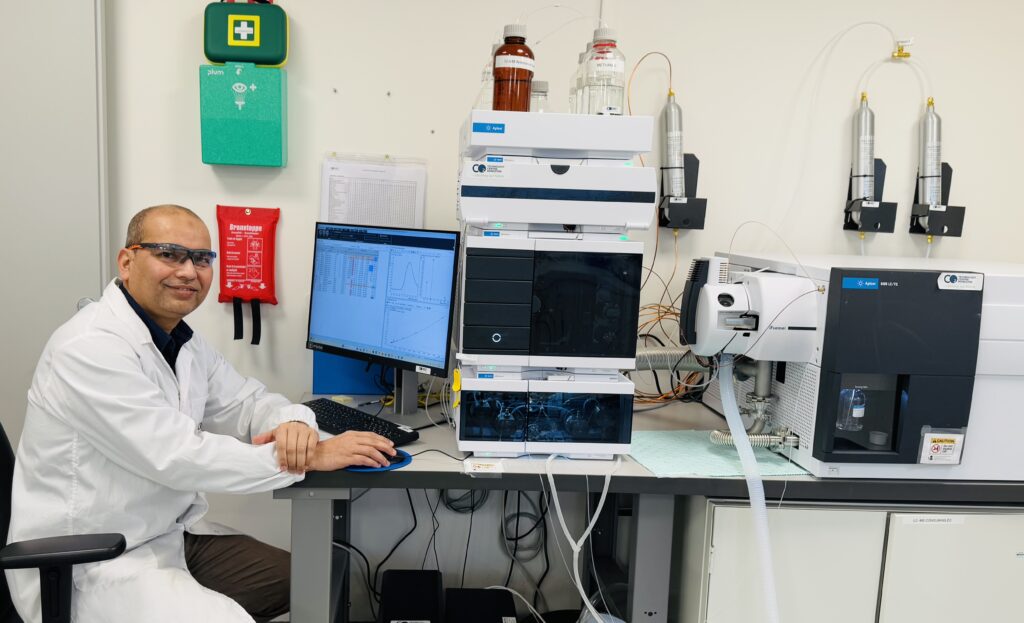

Koteswara Rao Putta has been working for more than ten years, contributing to the development of CO2 capture technologies. The role in TCM’s Advisory Services is the one he enjoys the most.

“How did you become part of the TCM team?”

“It all happened during the COVID-19 pandemic. A few months before my contract at NTNU was set to end, I reached out to TCM’s Managing Director, Muhammad Ismail Shah, whom I had met at CCS conferences before. I told him I was looking for a job and would love to work at TCM. In December 2020, Ismail informed me that there was an opportunity available, but it was initially only for six months. Without hesitation, I said, “Yes, gladly!”

“How was your move from India to Norway?”

“I first moved to Norway for my PhD at NTNU. Fortunately, I already had friends there who were also pursuing their PhDs, which made the transition much easier socially. However, adjusting to the Norwegian winters was a challenge—especially the long, dark months with barely any sunlight. Back in India, I lived in a shared house with friends, so living alone was another big adjustment.”

“What surprised you most about Norwegian culture and behavior?”

“One of the biggest cultural surprises was navigating social dynamics in Norway. It was sometimes hard to tell whether the people I interacted with were friends or just acquaintances. One day, someone would be very open and friendly, and the next, it would feel as if we barely knew each other! It took me some time to understand that this is just how Norwegian social culture works. Now I have three close Norwegian friends 😊. Good relations take time to establish I believe.”

Name: Koteswara Rao Putta (39). Depending on where people are from, he goes by different names — Koti, Putta, or Koteswara. It’s a reflection of the diverse cultures he has encountered in his personal and professional journey.

From: A small village in Andhra Pradesh, India, about three hours from Bangalore.

Job: Technical Services Lead & Projects Coordinator

Education: Doctor of Philosophy (PhD), Chemical Engineering, from Norwegian University of Science and Technology (NTNU). Master, Chemical Engineering, from Indian Institute of Technology, Kanpur. Bachelor, Chemical Engineering, from Sri Venkateswara University (SVUCE), Tirupati, India

Work Experience: CO2 Capture Technology Consultant, CO2 Capture Technologist, Technical Services Lead & Projects Coordinator at TCM. Advanced Biofuel process Researcher at NTNU. ORISE Postdoctoral Researcher in Carbon Capture Simulation for Industry Impact (CCSI 2) at National Energy Technology Laboratory, USA. PhD Research Scholar, CO2 capture technology development. Syngas Technologies Process and Proposals Engineer at Haldor Topsoe.

Good at: Breaking down complex problems and analyzing solutions, innovating new ideas and approaches, and staying true to myself and my values

Cannot stand: Laziness at work, unnecessary waiting

Hobbies: Watching movies & TV series, reading & listening to philosophical ideas

Dreams of: I envision myself living amidst nature, just like my childhood — a small, cozy house surrounded by lush greenery, close to family and friends. I also dream of a small farm where I grow my favorite fruits and vegetables

“What inspired you to work with carbon capture?”

“Honestly, before starting my PhD, I didn’t know much about carbon capture. I have to thank my supervisors, Hanna Knuutila and Hallvard Fjøsne Svendsen at NTNU, for introducing me to the field. During my PhD, I was fortunate to meet pioneers like Professor Gary Rochelle from UT Austin, with whom our research group had an active collaboration. Later, at NETL in the USA, I was further inspired by the vision of my group leader, David Miller and the PSE team, along with other mentors. Their expertise and passion for carbon capture deepened my interest in the field.”

“Putta, how has your education prepared you for your role at TCM?”

“I consider myself lucky to have worked with the right people on relevant projects. The knowledge and skills I gained through those experiences made my transition to TCM smooth and enjoyable.”

“What is the most exciting aspect of your job at TCM?”

“Without a doubt, the Advisory Services role is the most exciting. Engaging with clients, addressing their questions, and finding innovative solutions keeps the work dynamic and rewarding.”

“Can you share a specific project at TCM that you’re particularly proud of?”

“One project I’m particularly proud of is my first at TCM, designing a CO2 capture pilot plant for Wärtsilä. It was quite challenging due to various constraints and modifications that arose during the project. I ended up running 20–30 different simulations to refine the design—it was intense but also a lot of fun!”

“What do your family and friends say about your job?”

“They believe I’m doing meaningful work, and some even find it exciting. Many have said, “This is something that truly needs to be done for future generations,” which is always encouraging to hear.”

“What gives you energy and joy at work?”

“I find great energy and joy in running simulations and uncovering solutions to complex challenges, particularly in our Advisory Services. The thrill of problem-solving—analyzing data, fine-tuning models, and providing actionable insights—keeps me motivated every day. Knowing that my work contributes to real-world solutions in carbon capture and sustainability makes it even more rewarding.”

“What do you think is the biggest challenge in your work?”

“One of the biggest challenges is the limited ability to test new ideas due to the complexity and time required to implement new projects. There are many innovative concepts I’d love to explore, but practical constraints sometimes slow down the process.”

“If you were to give a colleague a flower, who would it be—and why?”

“I would give a flower to my manager, Matthew Campbell, for his constant encouragement, support, and valuable feedback. His leadership has made a significant impact on my journey at TCM.”

“What do you value most about your colleagues at TCM, Putta?”

“Their knowledge and experience in solving problems. Collaborating with such a talented and experienced team is both inspiring and a continuous learning opportunity.”

“How do you recharge after a long day at work?”

“Spending quality time with my child is the best way to unwind—it instantly shifts my focus from work to joy. Whether it’s playing together or simply enjoying their laughter, it recharges me like nothing else. Later in the evening, I like to relax with a good TV show, letting my mind drift away from the day’s challenges. That combination of family time and entertainment helps me reset and recharge for the next day.”

“What advice would you give to someone considering a move to Norway or a career in carbon capture?”

“I would encourage them to carefully consider cultural differences, lifestyle changes, and—most importantly—the weather and darkness. The winters can be challenging, especially for those coming from sunnier climates. I’d also advise checking if they already have friends or a support network in the place they’re moving to—it makes a huge difference.”

“What are your future plans?”

“I plan to continue advancing carbon capture and storage (CCS) while helping companies build expertise in this critical field. There’s still much to be done, and I look forward to playing a role in shaping a more sustainable future.”

CLIMIT Summit 2025: A Valuable Platform for TCM

The CLIMIT Summit 2025 in Larvik brought together over 350 participants from Norway and abroad for insightful discussions on CO2 management. Among the attendees were Technology Centre Mongstad (TCM) representatives, Managing Director Muhammad Ismail Shah and Business Development Manager Rouzbeh Jafari.

“The CLIMIT Summit provided an excellent opportunity to introduce our technology testing capabilities and advisory services to a diverse audience,” said Ismail and Rouzbeh.

Advancing CCS through Collaboration

Since its inception in 2005, CLIMIT has played a pivotal role in advancing Norwegian and international CO2 management solutions. The program—a collaboration between Gassnova and the Research Council of Norway—has supported over 800 projects focused on CCS research, development, and demonstration.

“This conference brought together key players in CCS. Unlike highly technical conferences, CLIMIT emphasized strategy and policy, giving us a new platform to showcase TCM’s capabilities to a broader audience,” said Rouzbeh.

During the summit, TCM also hosted a side event, presenting its role in CCS technology development. Chairman of the board Svein Ingar Semb emphasized that TCM is an important contribution to innovation systems to bring new technology to the market. The Technology Centre is a beacon for CO2 capture. Our goal is clear: to develop hands-on know-how, share knowledge, and contribute to technological solutions that reduce the technical, environmental, and economic risks associated with CO2 capture. It’s no secret that we are amid a global transition to a low-carbon economy.

“Our main message was that working with TCM benefits developers at any stage of technology maturation. Early-stage innovators can refine their strategies with TCM’s guidance, while those closer to commercialization can identify and bridge gaps in deployment,” Rouzbeh explained.

The summit also facilitated engagement with potential clients and partners.

“We connected with stakeholders not only in carbon capture but also in transport and storage. These discussions generated leads for future technology testing and collaboration at TCM,” Rouzbeh added.

International Perspectives and Key Recognitions

At the conference, Mark Ackiewicz from the U.S. Department of Energy provided insights into America’s expanding carbon management initiatives. With 19 operational facilities and over 200 CCS projects underway, the U.S. is rapidly scaling up its capture, transport, and storage capacity.

“Ackiewicz emphasized the significance of international partnerships, particularly with Norway and TCM, in advancing CCS technologies. We look forward to continued collaboration with U.S. technology developers to achieve long-term climate goals,” said Ismail.

A highlight of the event was the CLIMIT Award, which recognized individuals for exceptional contributions to CCS advancement. This year’s award honored three pioneers behind the Longship project:

- Oscar Graff

- Per Brevik

- Philip Ringrose

“Under Oscar Graff’s leadership at Aker (now SLB Capturi), CO2 capture technology evolved from lab testing to large-scale implementation at TCM. Today, it is being deployed at full scale at Heidelberg Materials’ cement plant in Brevik, the first capture facility of the Longship project. On behalf of TCM, I congratulate Graff on this well-deserved recognition,” said Ismail.

Venstre deputy leader visits Mongstad and TCM

Member of Parliament and Deputy Leader of Venstre, Sveinung Rotevatn, took his time when he visited Nordhordland on the last day of February to be briefed on developments in the industrial cluster at Mongstad.

There are over 60 companies at Mongstad, with a total of approximately 3,500 employees, with Equinor Mongstad being the largest.

17 different capture technologies

The visit began with presentations at the refinery, which is celebrating its 50th anniversary this year. During the visit, the Managing Director of TCM, Muhammad Ismail Shah, also provided an overview of the role the technology center plays in making carbon capture and storage (CCS) a powerful tool in the global climate fight. Since its inception in 2012, 17 different capture technologies have been tested at TCM. Most full-scale capture facilities currently being planned or built in Europe and the USA will use technologies that have undergone extensive testing at the world’s largest CO2 capture test center at Mongstad.

A gift to the world

“It is safe to say that TCM has been a gift to the world,” said Shah, emphasizing the ambitions he and his colleagues have to contribute to the success of Norway’s first major CCS project, Longship, and future projects that will follow. “More and more industries are considering projects with qualified technologies to remove or reduce their emissions. The costs of CO2 management can be reduced in parallel with the adoption of the technology—through continued testing and development. TCM is, and will remain, an important arena for reducing risk and accelerating the scaling of carbon capture technology.”

It was Einar Vaage, project manager at Greenspot Mongstad, who invited Sveinung Rotevatn to Mongstad, and the guest expressed gratitude for an interesting and informative day. The visit concluded with a bus tour around the refinery and a stop at its esteemed neighbor, TCM.

TCM’s Pivotal Role in Advancing MOF-Based CO₂ Capture Technologies

“The successful outcomes from the MOF4AIR project have attracted interest from various industrial partners looking to implement efficient and cost-effective carbon capture solutions. At TCM, we actively supported our project partners in advancing the technology along its path to commercialization,” says Ahmad Wakaa, Onsite Testing Manager and Senior CO2 Capture Technologist at Technology Centre Mongstad (TCM).

The MOF4AIR project, funded by the EU’s Horizon 2020 research and innovation programme, united 14 partners from eight countries to develop and demonstrate Metal Organic Framework (MOF)-based CO2 capture technologies for power plants and energy-intensive industries. TCM was the Norwegian demonstration site in this initiative, conducting the test campaign at the Site for Emerging Technologies (SET).

The project commenced in 2019 and concluded with a final workshop in Brussels, Belgium, in January 2025. Among the invited speakers was Ahmad Wakaa, who shared insights from TCM’s involvement in the project.

“You have followed MOF4AIR from the very beginning. Can you explain the main principles of this capture technology?”

“Metal Organic Frameworks (MOFs) are porous materials composed of metal ions coordinated to organic ligands, forming three-dimensional structures. Their high surface area and tunable porosity make them excellent candidates for gas adsorption applications. In CO2 capture, MOFs can be engineered to selectively adsorb CO2 molecules from flue gases emitted by power plants and heavy industrial processes. Selective adsorption occurs by designing MOFs with specific pore sizes and chemical functionalities that enhance CO2 affinity. Once saturated with CO2, MOFs undergo vacuum desorption, enabling CO2 collection for storage or utilization while allowing the material to be reused in multiple cycles.”

“What have been the most important outcomes and learnings from the project?”

“The MOF4AIR project successfully demonstrated that MOF-based adsorption processes could be effectively integrated into existing industrial setups for CO2 capture. Key outcomes include identifying and scaling up the most promising MOF materials, optimizing adsorption processes such as Vacuum Pressure Swing Adsorption (VPSA), and validating these technologies in real industrial environments. The project also provided valuable insights into the stability, selectivity, and regeneration efficiency of MOFs under operational conditions, paving the way for future advancements in carbon capture technologies.”

“What can you say about the test campaign at TCM? What kind of value has it provided for the project’s results?”

“At TCM, we conducted a comprehensive test campaign focusing on evaluating the performance of selected MOF materials under realistic flue gas conditions. These tests were crucial in evaluating the durability and efficiency of MOFs in capturing CO2, particularly from refinery RFCC gas.The collected data provided empirical evidence for the feasibility of MOF-based capture systems and guided further adsorption process optimization. Our findings contributed significantly to the project’s overall assessment of MOF technologies’ readiness for industrial application.”

“What were your main messages in the presentation you gave in Brussels?”

“In my presentation at the final workshop in Brussels, I emphasized the successful integration of MOF-based adsorption processes into existing industrial frameworks, highlighting the operation stability of the MOF system and the promising results from our test campaign at TCM. I also emphasized the need for continued collaboration between industry, research institutions, and policymakers to accelerate MOF-based CO2 capture deployment.”

“In what way will research and development of MOF technology be continued?”

“Building upon the successes of the MOF4AIR project, future research will focus on further enhancing the performance of MOFs, particularly in terms of selectivity, adsorption capacity, and regeneration efficiency. Research will also focus on reducing production costs and enhancing the environmental sustainability of MOF synthesis. Pilot projects and larger-scale demonstrations are planned to validate the long-term performance and economic viability of MOF-based capture systems in diverse industrial settings. Collaborations with industry stakeholders will be crucial in tailoring MOF technologies to specific applications and facilitating their commercialization.”

“Are there any plans for the commercialization of this technology?”

“The positive outcomes from the MOF4AIR project have attracted interest from various industrial partners looking to implement efficient and cost-effective carbon capture solutions. Future efforts should focus on scaling up production, ensuring compliance with industrial standards, and conducting cost-benefit analyses to support market adoption. The transition from pilot-scale demonstrations to commercial applications will involve close collaboration between researchers, industry leaders, and regulatory bodies.”

“What has TCM learned from its work in the MOF4AIR project?”

“Through our involvement in the MOF4AIR project, TCM has gained valuable experience in integrating novel adsorption materials into existing carbon capture infrastructure. We gained valuable insights into the operational challenges and solutions of MOF-based capture systems, including material handling, process optimization, and scalability. This experience has enhanced our capabilities in evaluating and advancing emerging carbon capture technologies, reinforcing TCM’s position as a leading facility for testing and developing innovative solutions to mitigate industrial CO2 emissions.”

From Karachi to Mongstad: Zeeshan’s Journey in Science and Sustainability

With a deep passion for chemistry, sustainability, and technological innovation, Muhammad Zeeshan has built an impressive career in carbon capture research.

Muhammad Zeeshan is originally from Karachi, Pakistan, he moved to Norway in 2008, immersing himself in a new culture and expanding his expertise in environmental science. Over the years, he has made significant contributions to the field — combining research, project management, and mentorship.

Now, as Principal Researcher for Environment & HSE at TCM, Zeeshan plays a pivotal role in evaluating cutting-edge carbon capture technologies. From establishing a high-tech analytical lab to collaborating with global experts, his work is driving forward solutions for a more sustainable future.

“How did you become part of the TCM team, Muhammad?”

“I joined TCM through a combination of my academic background and extensive experience in research, project management, and supervising Ph.D. and Master’s students. My passion for amine-based and solid sorbent technologies, coupled with my expertise in Chemistry and analytical instruments, made TCM a perfect match. With a strong foundation in environmental assessments, chemical risk management, laboratory management and reaction mechanism & kinetics, I saw an opportunity to contribute to TCM’s mission. The prospect of advancing TCM’s lab, conducting HSE evaluations of new technologies, and collaborating with vendors made joining the team an exciting career move.”

”How was your move from Pakistan to Norway in 2008?”

“Moving to Norway was a transformative experience, both professionally and personally. I embraced a new culture, learned from diverse perspectives, and found immense opportunities for growth. Norway’s focus on innovation, equal opportunities, and a progressive work environment resonated well with my aspirations. It has been a rewarding journey that has enriched my life in countless ways.“

“What surprised you most about Norwegian culture?”

“The strong emphasis on work-life balance was one of the most surprising aspects. In many countries, long hours are a sign of dedication, but in Norway, efficiency and productivity during work hours are prioritized, while personal time is respected. Another unique aspect was ‘dugnad’—voluntary community work. The willingness of people to contribute to society without obligation reflects the collaborative spirit of Norwegian culture. It was inspiring to see how teamwork and shared responsibility are deeply ingrained in everyday life.”

“What inspired you to work with carbon capture?”

“My passion for carbon capture is deeply rooted in my commitment to sustainability and solving real-world environmental challenges. As a researcher, I’ve seen firsthand the struggles that carbon-intensive industries face in reducing emissions while maintaining efficiency. I was drawn to CCS because it offers a practical and scalable solution to mitigate climate change. The opportunity to develop and refine these technologies excites me every day, knowing that my work can contribute to a cleaner, more sustainable future.”

“How has your education prepared you for your role at TCM?

“My education provided a solid foundation for my role, equipping me with technical expertise in chemical risk assessment, reaction mechanism & kinetics, and atmospheric chemistry. Understanding the environmental impact of emissions and degradation products has been crucial in assessing carbon capture technologies. Additionally, my studies instilled a problem-solving mindset, enabling me to develop innovative, science-based solutions aligned with TCM’s mission.”

“What is the most exciting aspect of your job at TCM?”

“TCM offers a unique opportunity to test carbon capture technologies on an industrial scale. Collaborating with technology developers and research institutions allows us to solve real-world challenges. I particularly enjoy conducting environmental impact assessments, evaluating chemical risks, and ensuring compliance with HSE regulations. Engaging with the Norwegian Environment Agency and communicating findings is also a fulfilling part of my role.”

“Can you share a specific project at TCM that you’re particularly proud of?”

“I spearheaded an LC-MS (liquid chromatography – mass spectrometry) project, establishing a new lab from scratch. I acquired the LC-MS instrument, developed analytical methods to identify degradation products in CCS projects, and created a research proposal to involve master’s students. This project has become a key part of TCM’s research, demonstrating my 12 years of expertise in analytical instruments and my commitment to mentoring students. It’s rewarding to see our innovative methods contributing to the company’s growth.”

- Name: Muhammad Zeeshan (44)

- Marital Status: Married, three children

- From: Karachi, Pakistan

- Job: Principal Research Environment / HSE

- Education: Doctor of Philosophy (PhD), in Chemistry from Norwegian University of Science and Technology (NTNU). Master of Philosophy (M.Phil.), Natural Products Chemistry from International Center for Chemical and Biological Sciences, Karachi.

- Work Experience: Principal Research Environment / HSE at TCM from January 2024 to present. Principal Research Scientist at TCM from January 2022 to January 2024, and Laboratory Leader at TCM from July 2021 – January 2022. Postdoctoral Research Fellow at University of Bergen (UiB) from August 2017 – June 2021. Lecturer at UiB for Advanced Organic Chemistry for two years. Research Scientist at UiT – The Arctic University of Norway from May 2013 – July 2017. Medicinal Scientist at NTNU from November 2012 – March 2013 and September 2011 – February 2012.

- Good at: Staying organized and managing multiple tasks efficientl

- Cannot stand: When tasks are left unfinished. I’m all about seeing projects through and delivering great results.

- Hobby: Cricket, Pro-Padel, reading books and scientific articles.

- Dreams of: Innovation of smart solution for CCS.

“What do your family and friends say about your job?”

“They see my work as a meaningful contribution to securing the future of our planet. My familiy admire my dedication and ability to balance work with a positive attitude. They often mention how I’m always willing to help others, offer guidance, and stay calm under pressure—traits that I find valuable in both my personal and professional life.”

“What gives you energy and joy at work?”

“Several things fuel my passion: solving complex problems, mentoring students, learning new things, and engaging in dynamic discussions with colleagues. The challenge of innovating and making meaningful contributions to CCS research keeps me motivated every day.”

“What do you think is the biggest challenge in your work?”

“Ensuring compliance with emission permits and preventing environmental violations is a crucial part of my job. Monitoring all emission sources, and minimizing unnecessary disruptions require constant diligence. Maintaining TCM’s strong environmental reputation is a responsibility I take seriously — but it’s also what drives me. The challenge of upholding the highest standards in emissions control pushes me to develop better solutions and continuously improve our processes.”

“Muhammad, if you were to give a colleague a flower, who would it be—and why?”

“There are many amazing colleagues at TCM, but if I had to choose one, I would give a flower to Gøril Nyhammer-Haugen for her kindness and unwavering support. She is always ready to help, bringing positivity and warmth to those around her. Flowers symbolize resilience and encouragement—qualities that perfectly reflect the way she uplifts others and creates a welcoming, motivating work environment.

“What do you value most about your colleagues at TCM?”

“The collaborative spirit and knowledge-sharing culture. We tackle challenges as a team, supporting and inspiring one another. Their expertise and professionalism make every project a valuable learning experience, and their commitment to innovation drives both my professional and personal growth.”

“How do you recharge after a long day at work?”

“I unwind by reflecting on the day’s achievements and planning for the next. Spending time with my twin children, cooking, exercising, and watching movies with my family helps me recharge. I also enjoy helping my eldest son with his homework — it’s a rewarding way to end the day.”

“What advice would you give to someone considering a move to Norway or a career in carbon capture?”

“Norway is a global leader in CCS, with initiatives like Longship and Northern Lights paving the way. Familiarizing yourself with these projects can provide a strong advantage. Developing expertise in engineering, chemistry, environmental science, or project management is crucial, and specialized training or certifications can enhance career prospects in this field.”

“What are your future plans, Muhammad?”

“I aim to take on more challenging projects, expand my expertise in CCS, and lead innovative initiatives. I also want to develop my leadership skills and contribute to groundbreaking solutions in carbon capture and storage.”

Yes-man Who Loves Technical Challenges

Stig Åge Vabø is the Technical Property Supervisor at TCM. With more than 30 years of experience in construction-related fields, he ensures that advanced ventilation, energy, and security systems operate seamlessly.

Known for his positivity and hands-on approach, he is an integral part of the TCM team. Stig admits that he cannot stand saying no, which naturally makes him excellent at saying yes.

As the Technical Property Supervisor at TCM, Stig Åge Vabø has a lot to oversee and follow up on. Here, he is inspecting an electrical cabinet.

“Stig, How did you become part of the TCM team?”

“In 2017, we moved from Bergen to Lindås, but the company I worked for still had its office at Danmarksplass in central Bergen. After repeatedly getting stuck in traffic on my way home, I decided to look for a job closer to home. A position at TCM came up almost by chance. I was thrilled to get the offer and haven’t regretted it for a single day.”

“Did you know much about carbon capture before joining TCM?”

“I actually knew what TCM was working on because I helped install CCTV and access control systems during the construction phase.”

“What’s the most exciting part of your job at TCM?”

“What excites me most is that my job as a Technical Property Supervisor is both strategic and hands-on. This combination allows me to me to constantly learn new things. I’m passionate about technology, and problem-solving and the interaction between people and buildings are rewarding and exciting. No two days at TCM are the same. I appreciate being challenged with new tasks and take pride in ensuring that everything related to the building’s technical systems operates flawlessly.”

- Name: Stig Åge Vabø (58)

- Marital status: Married, three children, one foster child, and four grandchildren

- From: Bergen

- Job: Technical Property Supervisor

- Education: Master craftsman certificate in glazing from the Leadership School in Bergen

- Work Experience: Technical Property Supervisor at TCM, 2018 – present. Consultant/Project Manager at Dormakaba, 2013 – 2018. Project Technician at Infratek, 2008 – 2013. Locksmith at Certego, 2002 – 2008. Glazier at Bue Aluminium, 1992 – 2002

- Good at: Saying yes

- Cannot stand: Saying no

- Hobby: Cycling, boating, and skiing

- Dreams of: A trip to Machu Picchu in Peru

“What does a typical workday look like for you, Stig?”

“The TCM administration building is equipped with advanced systems for ventilation, heating, and cooling (HVAC), which require daily monitoring and maintenance. I’m also responsible for electrical systems, fire alarms, access control, and smart building solutions that optimize energy use. My job is to ensure these systems are functioning and well-maintained. When technical issues arise, I troubleshoot and work to resolve them quickly to ensure that operations, whether in the control room or the laboratory, are not affected. I also manage compliance with mandatory inspections and certifications for the building’s technical systems.”

When technical issues arise, Stig Åge Vabø has to troubleshoot. “I try to find solutions as quickly as possible so that operations, for example in the control room or the laboratory, are not affected.

“Who do you work most closely with, and how is the collaboration?”

“I’m part of the Finance & Administration department, which is a small but efficient service team for the rest of the organization. With such a wide range of responsibilities, teamwork is essential. The collaboration within our team works excellently.”

“What gives you energy and joy at work?”

“I thrive most when I manage to resolve technical issues quickly as they arise. I also find great joy in helping colleagues who might be stuck with a technical problem and seeing the solution work. Often, it doesn’t take much, but it’s highly appreciated. People at TCM are kind to one another, and I value that a lot—it’s not something you can take for granted at every workplace.”

“You hold a master craftsman certificate as a glazier. Does this come in handy at TCM? And how has your past work experience shaped your role, Stig?”

“The master certificate proves both technical expertise and qualifications for running a business. My first trade was as a building glazier, which is helpful for maintaining the doors and windows on the building. I’ve also worked as a locksmith, which is valuable when dealing with over 70 electronic locks at TCM. Additionally, my experience as a service technician in electronics has been beneficial for managing access control and HVAC systems.”

“What do your family and friends say about your job?”

“Some say I’m part of Stoltenberg’s ‘moon landing project.’ This gives me the chance to explain how vital carbon capture technology is for achieving climate goals, both in Norway and globally. It’s exciting to highlight how TCM’s work contributes to a cleaner, more sustainable future. The overall impression is that I work at an innovative workplace with great significance for the future.”

“What do you find most challenging about your job?”

“My biggest headache is dealing with external suppliers who don’t deliver as expected or fail to meet agreements. Although this can be frustrating, I focus on finding practical solutions and fostering open communication to ensure expectations are met.”

“If you were to give a flower to a colleague, who would it be—and why?”

“It would have to be Sara Eriksson, who was named TCM’s best chef just a few months into her role. Going to lunch and enjoying the wonderful meals she prepares is an absolute pleasure.”

“Stig, How do you recharge after a long day?”

“I usually take a walk with our dog, the happiest Portuguese Water Dog in the world—though, ironically, she’s a bit afraid of water. In the summer, I enjoy spending time on the water in a boat or kayak, and in the winter, I love skiing. It’s a refreshing way to recharge both physically and mentally.”

“What are your thoughts about the future?”

“Looking ahead, I feel fortunate to work at a place where innovation meets an important purpose. It’s incredibly rewarding to know that what we do contributes to a sustainable future. My hope is to keep playing my part in this important mission until I retire.”