We impart knowledge

Our long experience on testing leading commercial technology and recognized research-based technologies, has made TCM a world-leading competence center within CO2.

A world-leading competence center

We share knowledge and experience from research activities with the entire global environment in carbon capture and storage, through publication in renowned scientific journals and presentation at scientific conferences.

Below you will find our summary of some of the articles that have been published.

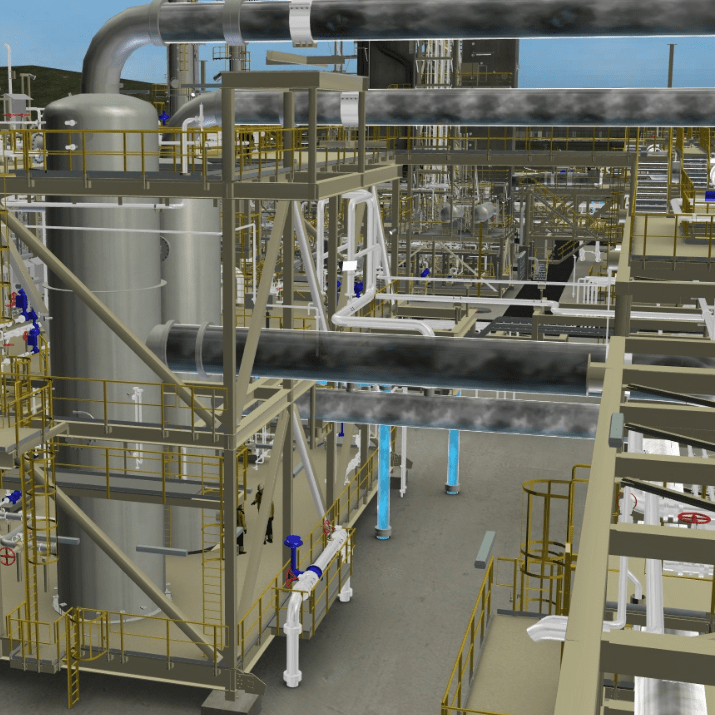

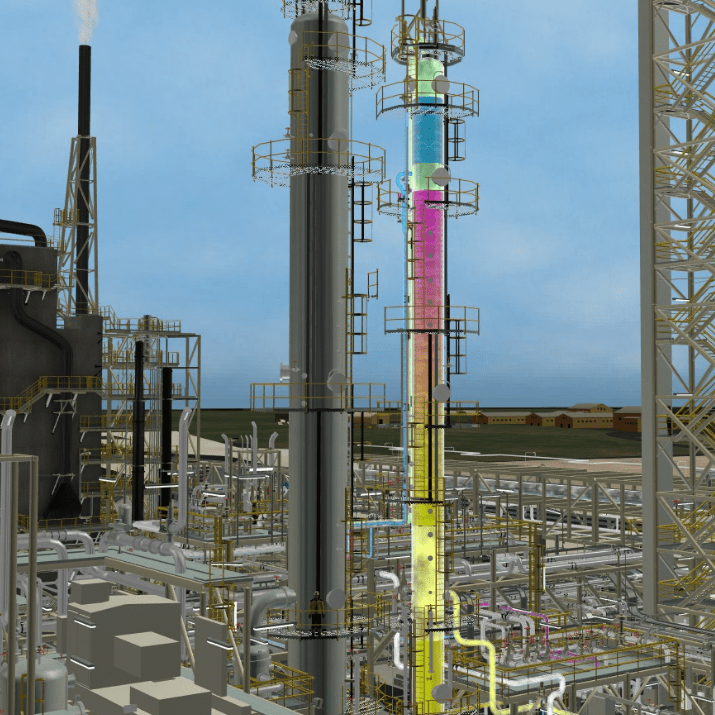

TCM Design & Construction

In this series of reports, you can read about our experiences of building a carbon capture facility and the sorts of knowledge TCM built up over this period. These experiences are used when we advise on upcoming CCS projects. We have experienced and learned a lot about air emissions and the experience gained from the design is useful to this day.

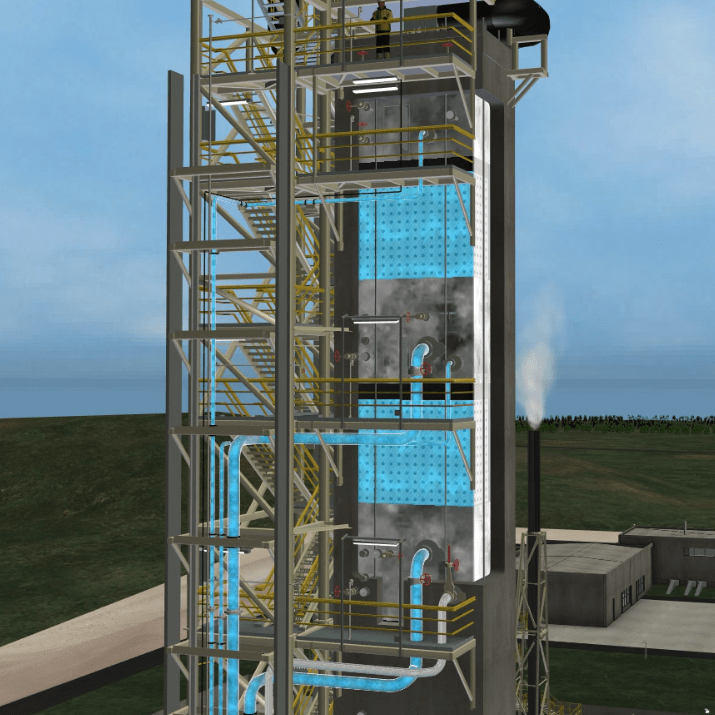

Operational Experience & Results

In this series of reports, you can read about our experiences of operating carbon capture facilities with a range of capture technologies and CO2 concentrations. These experiences are based operation of the amine plant (mainly with non-proprietary MEA and CESAR1 solvents), Chilled Ammonia Process (CAP) plant and the dedicated Site for Emerging Technologies which tests next generation capture technologies such as membranes and sorbents.

Verified baseline results

Some of TCM’s testing has been with the non-proprietary MEA and CESAR1 solvents, which are studied extensively in research and academia and can be used as benchmarks for new or proprietary capture technologies. Testing these non-proprietary solvents for thousands of hours at the scale of the TCM amine plant, with real flue gasses, has unlocked many new learnings for the industry, shared via open publications and TCM’s Advisory Services.

In collaboration with the Electric Power Research Institute (EPRI) (lenke inkl. LinkedIn), an independent US energy R&D body, TCM have tested and published a number of verified baseline conditions with MEA & CESAR1 with CHP and RFCC flue gas.

Emissions – Limits, Measurements and Mitigation + Aerosols & Mist

One of TCM’s biggest focus areas has been on airborne emissions released from carbon capture processes, and this has been the case since the plant was built. Working in collaboration with other research communities and technology suppliers, we have sought to identify and deploy robust methods that ensure we adequately manage and monitor this issue.

Solvent Degradation, Management and Reclaiming

Experience from more than ten years of operations at TCM shows that it is essential to have full control of the entire capture process and of what is happening around the capture facility. TCM’s experiences show that you almost cannot be thorough enough.

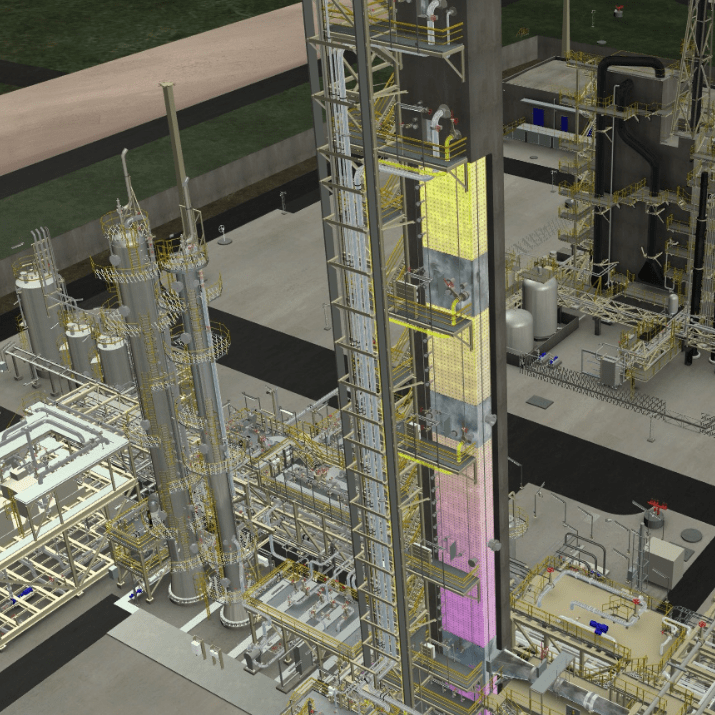

Process modelling, scaling up and cost reduction

Through many years of experience with CO2 capture technology, TCM has built up a broad knowledge of what is needed to reduce costs linked to the capture process itself.

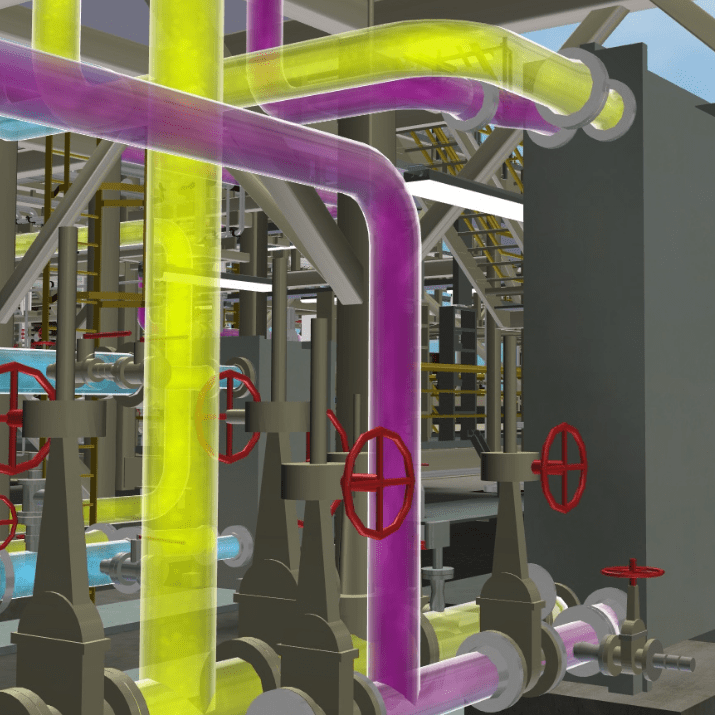

CO₂ Capture – Operational and process control

Through more than 10 years of technology testing campaigns with 24/7 operation. TCM have developed significant learnings and experience in this area predominantly on the flexible amine plant but also on other TCM test sites.

Corrosion and materials

TCM has learned that attention must be paid to all parts of the capture process. Something that is easy to forget is the effect of capture chemicals and CO2 itself on various materials of construction.