07.04.2022

We have learned a lot; Site for Emerging Technologies

TCM’s 10 years of testing to date have helped development and de-risking of various carbon capture technologies with the goal of enabling the deployment of successful full scale capture projects.

The majority of TCM’s testing in this period has been on amine solvent-based carbon capture. However, over the same 10-year period, less mature technology alternatives to conventional solvent-based carbon capture processes such as membrane systems, sorbent systems or the use of novel solvent types or rotating capture beds have become an increasingly important topic in the CCUS community.

Technology Readiness Level (TRL)

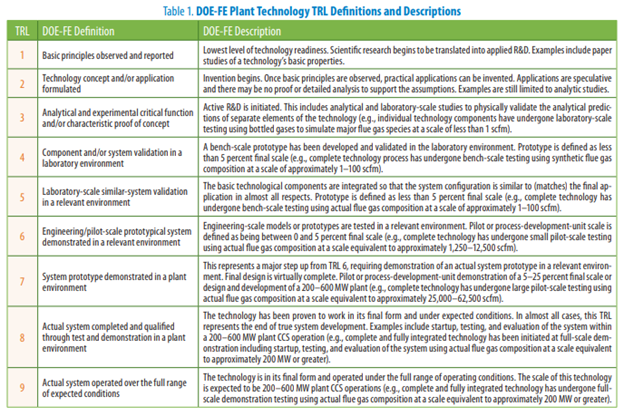

A common system for assessing the maturity of a technology from initial concept through to widespread industrial uptake is a Technology Readiness Level (TRL) scale. There are various versions of this scale available, with many companies using their own internal scale and definitions. One common scale used for assessment of carbon capture technologies is the US Department of Energy scale, shown below, which focuses on the readiness of a capture technology for full-scale power generation applications.

Using this scale, a successful demonstration in TCM’s solvent-based amine or chilled ammonia plants, with capture capacities up to 75,000 tonnes of CO2 per year, would enable a technology to demonstrate a TRL of 7 on the DoE scale.

TCM Site For Emerging Technologies

In 2021, TCM began testing on its new “Site for Emerging Technologies” which is designed for smaller scale testing of lower TRL technologies when compared to the TCM amine and CAP facilities. With the capacity to capture up to 18,000 tonnes of CO2 per year, his area of TCM (shown in the paved area below) is a “plug & play” testing area where technology developers can test skid-based capture systems with real flue gas and utilities provided by TCM while benefiting from the specialist knowledge and experience of TCM personnel.

As mentioned, technologies typically best suited for testing at the TCM Site for Emerging Technologies would be at a smaller scale and lower TRL than those tested in the amine or chilled ammonia test facilities. However, many of these technologies are based on modular designs of standardized size in which the scale-up strategy is simply to increase the number of modules for the required application. Hence, demonstration of a single module at the TCM Site for Emerging Technologies can enable significant development of the technology towards full scale.

At the Site for Emerging Technologies, TCM can provide technology developers with:

- Up to 10,000 Sm3/h of real flue gas

- “Dirty” or treated Fluidized Catalytic Cracker (FCC) flue gas at 14% CO2

- Clean gas boiler flue gas at 8% CO2

- Facility to dilute flue gas with air or enhance the CO2 content by recycle.

- Utilities: including seawater, process water, electrical power, instrument air and drains.

TDA & MTR at the Site For Emerging Technologies

The first two test campaigns on the Site for Emerging Technologies were successfully completed in early 2022. These projects were both funded by the US Department of Energy/NETL and are now in the decommissioning and reporting phase of their respective tests at TCM. Both TDA & MTR have submitted abstracts for the GHGT-16 conference based on the experience and results from their tests at TCM.

TDA’s hybrid sorbent membrane system, shown at TCM in the picture below, is a 2-stage process with a membrane based and a sorbent-based capture step. For further details on TDA’s technology, their test goals at TCM and their vision for full-scale applications, please see their 2021 NETL Project Review Meeting presentation.

“Running a field test in the midst of a global pandemic presented a number of new challenges, but we are pleased with the results of the test campaign nevertheless and are delighted with the system up-time we experienced throughout the campaign. Having the support from TCM and the experienced team in Norway was tremendously valuable. TDA looks forward to future opportunities to test at and collaborate with TCM.” – David Gribble, Senior Scientist at TDA

Membrane Technology Research’s (MTR) membrane system, shown in the picture below, is a multi-stage membrane process. For further details on MTR’s technology, their test goals at TCM and their vision for full-scale applications, please see their 2021 NETL Project Review presentation.

“The opportunity to test with real flue gases at a world-class facility like TCM has been an important development step for our membrane carbon capture technology. The support from TCM personnel during all project phases was instrumental in the success of the field test”, said Tim Merkel, VP of Technology at MTR.

Future Campaigns

Interest in testing at the TCM Site for Emerging Technologies has been high, with the following projects scheduled to test there in 2022-23:

- MOF4AIR – Part of an EU project aiming to develop and demonstrate the use of metal-organic framework materials for carbon capture. They will test a sorbent-based pilot system at TCM. See https://www.mof4air.eu/ for further information

- ACCSESS – Part of an EU project aiming to provide cost efficient, replicable, safe and flexible CCUS. They will test a pilot system using an enzymatic solvent and rotating packed bed (RPB) absorber at TCM. See https://www.projectaccsess.eu/ for further information.

- Innosepra- Funded by the US Department of Energy/NETL, Innosepra aim to demonstrate their sorbent-based system for carbon capture at TCM. For further information, please see Innosepra’s 2021 DOE Project Review Meeting presentation.