We are advisors

Technology Center Mongstad (TCM) assist industries to successfully adopt technologies that will help them achieve their carbon emission mitigation goals.

We share our knowledge on carbon capture

After many years of scientific research and commercial operation of the world’s largest CO2 test facility, we have gained unique knowledge of carbon capture technology that we share with carbon capture project developers.

To maintain neutrality in our relationship with different organisations, TCM does not recommend specific technology solutions or share information about tests conducted by commercial actors. Instead, we help our clients become informed buyers of carbon capture technology. For example, our consultants can provide quality assurance for technology procurement frameworks. We help you, the customer, to ask the right questions to select a cost-effective solution and to manage projects in a safe, time-saving and cost-effective way.

Our contribution to international carbon capture deployment

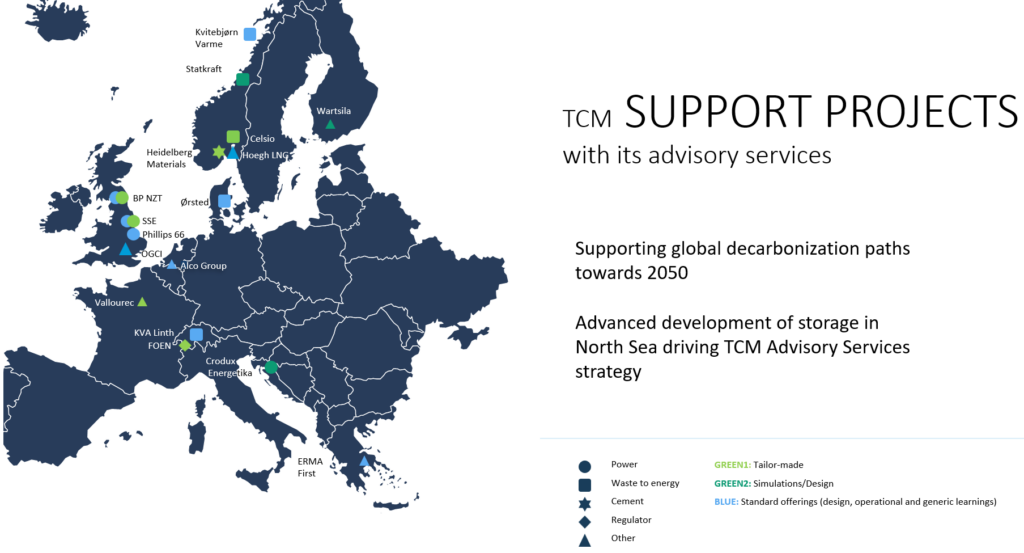

TCM has provided consultancy services to a number of carbon capture and storage development projects.

In connection with the Norwegian Longship project, we have contributed our expertise to the planned full-scale project for Hafslund Celsio in Klemetsrud, Oslo. We also plan to support the operation of the capture plant at Heidelberg Materials’ cement plant in Brevik.

TCM has also advised a number of international industries. See the map below for more details.

Working with SINTEF and DNV

Together with SINTEF and DNV, we offer joint global consulting services on capture, transport and storage of carbon dioxide. Our focus in this collaboration is on the CO2 capture step of this process.

SINTEF is one of Europe’s largest independent research organizations and has a long history and broad portfolio within CSS R&D projects. SINTEF’s activities range from molecular modelling to industrial pilot testing. DNV has a global presence and is a highly acknowledged certification body with well-established and standardized technology qualification programs. Together, we constitute a unique global force within consulting services on carbon capture and storage.

Why you should use our advisory services

TCM has a long-standing expertise in operation, troubleshooting and upgrading of a plant that annually capture up to 100,000 tons CO2. We offer extensive analytical tools and a laboratory with highly specialized capabilities, including manual isokinetic gas sampling. Our business and procedures consider material integrity, including chemistry, corrosion, control systems, inspection, environmental management and work environment monitoring. TCM provides development of technology assessment procedures, data acquisition, analysis & QA vital for technology qualification, and we are devising intervention strategies to improve technology performance.

At our plant you are secured high safety and sustainability of processes through systematic assessment, practical improvements and raised awareness; i.e. our unparalleled insight in emission monitoring under the most stringent authority standards. Our promise is that you save both time and money by choosing advisory services from TCM.

Services – Standard Offerings

Services – Simulations

| Topic Title | Description of work |

| Design Basis | TCM to have workshop with customer to define the Design Basis for the design of CO2 capture cases to be simulated. This includes participation in Teams workshops/meetings. |

| Process simulation – Base case CO2 concentration and operational window | TCM to develop a steady state process model for customer case based on TCM verified MEA model in Aspen Plus. This includes: ·A description of the simulation tool including the performed validation. ·Overall process description including PFD. ·Using the model to simulate customer base case for the design case. ·Heat and Material Balances will be generated including electric power consumption, steam consumption and cooling water consumption. ·Participation in Teams workshops/meetings |

| Process simulation – other conditions | ·Using the model to simulate customer other conditions case for the design case. ·Heat and Material Balances will be generated including electric power consumption, steam consumption and cooling water consumption. |

| Input for initial sizing of major equipment | ·TCM will provide one preliminary sizing for major equipment, such as absorber column (height, diameter, packing type), stripper column (height, diameter, packing type), Rich/Lean heat exchanger (area requirement for heat transfer), water wash section, flue gas Blower (electric power requirement), and Direct Contact Cooler (height, diameter, packing type). |