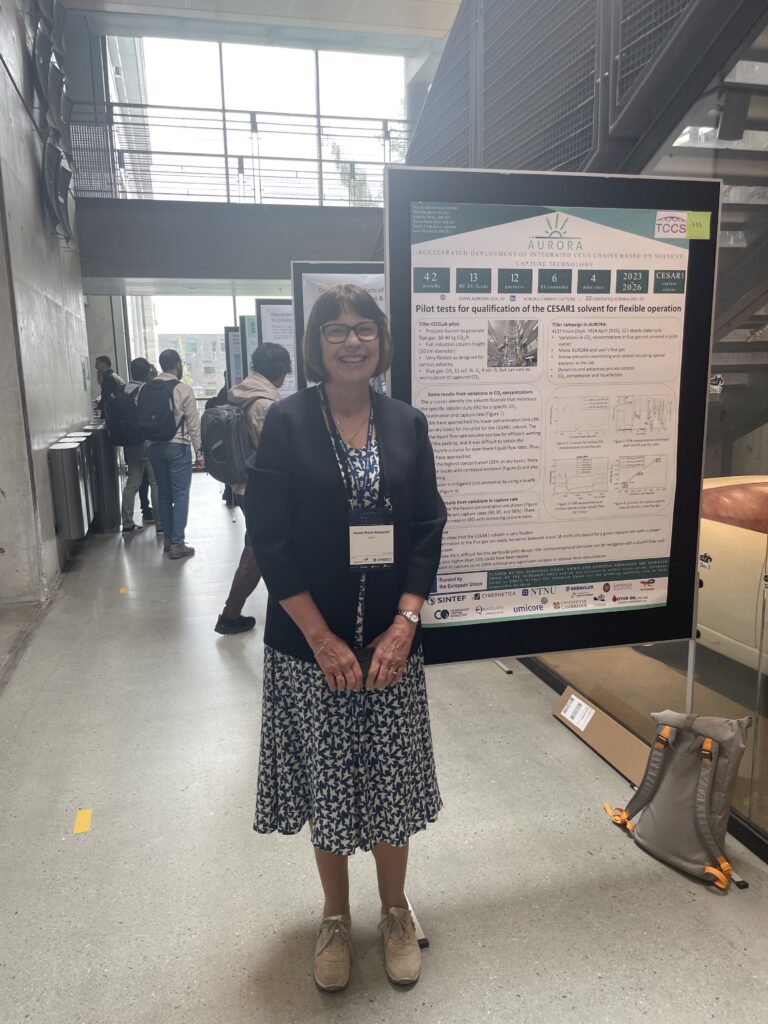

The AURORA Campaign at TCM a Success

“The campaign at TCM to test the advanced CO2 capture solvent CESAR1 was a success,” says Chief Scientist Hanne Marie Kvamsdal at SINTEF. She leads the EU-funded AURORA project, which aims to qualify CESAR1 for commercial use.

The four-month test campaign at Mongstad concluded in September, and SINTEF’s work to analyze the key results in its specialized laboratory is now in its final phase.

“Before starting the campaign at TCM, we were somewhat concerned that the solvent might precipitate and form problematic solid particles when tested with different flue gases containing various impurities – but fortunately, that did not happen. The team at TCM, led by Koteswara Rao Putta, delivered flawlessly on all the parameters we wanted to test during this intensive campaign,” says Kvamsdal.

CESAR1 Has Unique Properties

The test campaign at Mongstad formed an important part of the large AURORA project, which started in 2023 and will be completed next year. The project is funded through the EU Horizon programme with a total budget of approximately NOK 200 million.

At the core of the project is the non-proprietary solvent CESAR1, which is being verified for its commercial applicability in CO2 capture, including in refineries, the cement industry, and metal recycling facilities. The working hypothesis is that CESAR1 stands out with high efficiency, low emissions, and significantly reduced energy demand compared to conventional amine-based capture solutions such as MEA (monoethanolamine).

“The final answer to this key question for large-scale CCS deployment will be presented at a conference organized by the consortium in Paris in 2026. Representatives from the European Commission, industry, and leading research institutions across Europe will be invited,” Kvamsdal explains.

Strong Industrial Interest

Kvamsdal emphasizes that the AURORA project has been met with strong interest from industry. At the IEAGHG conference in Marseille in September; a comprehensive presentation of the large-scale CESAR1 testing at TCM was delivered – generating both recognition and high expectations among industrial stakeholders.

“In the coming months, based on the test results from TCM, we will simulate four cases using CESAR1 – at a refinery in Belgium, a refinery in Greece, a cement plant in Greece, and a recycling facility in Belgium. There is still considerable analytical work ahead before we can draw final conclusions and provide our recommendations to the project’s sponsor. But we are confident that CESAR1 will prove valuable in the effort to reduce climate emissions from key industries,” Kvamsdal concludes.

Read more about the AURORA campaign at TCM:

https://tcmda.com/news/the-future-of-co%e2%82%82-capture-is-being-tested-at-tcm

Read more about what happens to CESAR1 during CO2 capture:

https://tcmda.com/news/new-study-reveals-what-happens-to-cesar1-during-co%e2%82%82-capture

Learn more about the AURORA project:

https://www.sintef.no/en/projects/2023/aurora-accelerated-deployment-of-integrated-ccus-chains-based-on-solvent-capture-technology/

TCM made its mark in Hamburg

For the second year in a row, Technology Centre Mongstad (TCM) had a strong presence at the Carbon Capture Technology World Expo in Hamburg.

Technology Manager Matthew Campbell and Communication Officer Liv Lønne Dille experienced interest from industry representatives eager to learn more about TCM’s work and experience in testing CO2 capture technologies.

The interest is there

Visitors from various industry sectors were particularly interested in learning how CO2 capture plants handle impurity variations from different flue gases. Also, there was tremendous interest to learn about TCM experience with the non- proprietary CESAR 1 solvent. Some were representatives of companies with their own technology concepts, while others wanted to know how they could start learning about carbon capture.

“Many companies wanted us to follow up afterwards for further dialogue, and TCM’s business development team will now take care of this,” says Lønne Dille. We are already working on this.

TCM also facilitated contact between some of the visitors and Northern Lights in Øygarden, a company that specialises in commercial CO2 storage, forming a natural link between capture and storage. Given that we have different roles in the CCS value chain, it is important to promote each other. There is a need for a better understanding of how things are connected.

“We hope that the meetings we had in Hamburg can lay the foundation for new collaborations and exciting CCS projects,” says Matthew Campbell. At TCM, we are ready to welcome new visitors, hold initial discussions and embark on a journey towards potential future collaborations.

About the exhibition

The Carbon Capture Technology World Expo brought together more than 20,000 attendees over three days, along with 1,500 conference delegates and 300 speakers from around the world. The event is the largest international meeting place for carbon capture, utilization, and storage (CCUS), offering unique opportunities to build networks, exchange experiences, and discuss future solutions for a low-emission society.

TCM Strengthens Global Outreach – Growing Interest in Test Campaigns and Advisory Services

Technology Centre Mongstad (TCM) has recently intensified its international engagement to promote carbon capture test campaigns and advisory services.

In the past months, Managing Director Ismail Shah, and Business Development Manager Rouzbeh Jafari have met with potential clients across Canada, Europe, the Middle East, East Asia, and India, where the message has been clear: industries are seeking reliable, independent partners to help de-risk their CCS investments.

“We are seeing growing demand from emitters who want to test their solutions in a realistic and safe environment before moving into full-scale deployment,” says Rouzbeh Jafari. “At TCM, we can offer exactly that – the world’s most flexible open CO2 capture test facility, operating with real flue gas and delivering proven results.”

A Platform for Industrial Emitters

TCM offers testing of both proprietary and generic solvents, with tailored programs designed for key industrial sectors such as power generation, cement, steel, aluminum, waste-to-energy, and refining. The objective is to help companies establish a robust technical and economic baseline for future CCS decisions.

“Our clients benefit from independent validation of solvent performance, full ownership of test data, and access to TCM’s validated simulation tools,” Rouzbeh explains. “This gives them a competitive edge when entering FEED and commercial project phases.”

Through cost-sharing models and fast-track preparations, TCM provides an efficient, lower-cost pathway to capture testing. The center currently has available testing windows in 2026 and 2027, and TCM encourages early engagement to secure capacity and explore joint campaign opportunities with other industry players.

IMPURE-CO2: Unlocking the Next Step in CCS Infrastructure

One initiative drawing significant international attention is IMPURE-CO2 — a multi-partner project uniting leading R&D institutions, technology providers, and industrial emitters to address one of the most critical challenges in large-scale CCS deployment: managing impurities in the CO2 stream.

The project delivers scientific evidence for safe operations, validated predictive tools, and CO2 quality specifications — generating bankable data that reduce risk and accelerate infrastructure development.

“IMPURE-CO2 gives participants the opportunity to shape tomorrow’s standards and position themselves as technology leaders,” says Rouzbeh. “It’s about building trust – not only in capture technologies, but across the entire value chain from capture to storage.”

Beyond Testing

In addition to its world-class testing facilities, TCM offers advisory services for CCS technology evaluation and selection, as well as the TCM Operational Academy, which provides training for future capture plant operators.

“Our ambition is to be a full-service partner for companies implementing their decarbonization strategies,” Rouzbeh concludes. “At TCM, you don’t just test technology – you validate decisions that can accelerate the transition to a low-carbon future.”

Meet TCM at ADIPEC 2025

As part of its international outreach, TCM will participate in ADIPEC 2025, presenting under the theme “Decarbonizing Downstream through Scalable and Value-Driven Carbon Solutions.”

The presentation will take place on Wednesday, November 5, at 2:00 PM (local time) during the Downstream Technical Conference in Abu Dhabi.

This session will highlight TCM’s experience in enabling cost-effective, scalable CCS solutions for the oil and gas, energy, and industrial sector.

Ensuring Safe Operations in Amine-Based Carbon Capture at TCM

At the IEAGHG Conference PCCC-8 in Marseille, the Technology Centre Mongstad (TCM) shared new insights on personnel exposure and sampling methods related to amine-based CO2 capture.

The study presented at PCCC-8 highlights how TCM combines advanced technology testing with strict safety monitoring to protect both people and the environment.

Monitoring Exposure in Carbon Capture Operations

Decarbonising heavy industries is central to achieving the climate mitigation goals set out in the IPCC-6 report. Amine-based carbon capture is among the most mature technologies available today for reducing emissions from large industrial point sources. Since 2012, TCM has been at the forefront of testing and demonstrating both generic and proprietary solvents under industrial conditions.

A key part of this work concerns environmental and occupational safety. The process of removing CO2 from flue gas with amine-based absorption technologies introduces degradation products such as nitrosamines, which are classified as potentially carcinogenic. Early in TCM’s operations, the Norwegian Institute of Public Health (NIPH) assessed potential health risks and set strict safety thresholds. Since then, TCM has carried out extensive monitoring to ensure compliance and to safeguard personnel.

Findings from more than ten years of testing show that nitrosamines can be present during campaigns, but median and average background concentrations are very low—well below today’s occupational exposure limits. Both stationary and personal sampling methods have been applied to better understand exposure levels. Current research also aims to address uncertainties linked to sampling methods through new laboratory experiments.

Keeping Carbon Capture Both Effective and Safe

“Protecting the health and safety of our personnel is a top priority,” said Alexander Reyes Andersson. “Our monitoring results show that exposure levels are generally low, but we continue to study this in detail to close knowledge gaps and ensure that carbon capture operations remain both effective and safe.”

By combining rigorous safety assessments with cutting-edge technology testing, TCM strengthens its role as a global hub for advancing carbon capture solutions—supporting both industrial decarbonisation and safe workplace practices.

Co-writer: Fred Rugenyi

TCM Showcased Key Advances in Carbon Capture at IEAGHG Conference

At the IEAGHG Conference in Marseille, the Technology Centre Mongstad (TCM) presented new results from industrial-scale carbon capture testing and highlighted how machine learning can improve environmental monitoring.

The contributions reinforced TCM’s position as a leading test facility for accelerating global carbon capture solutions.

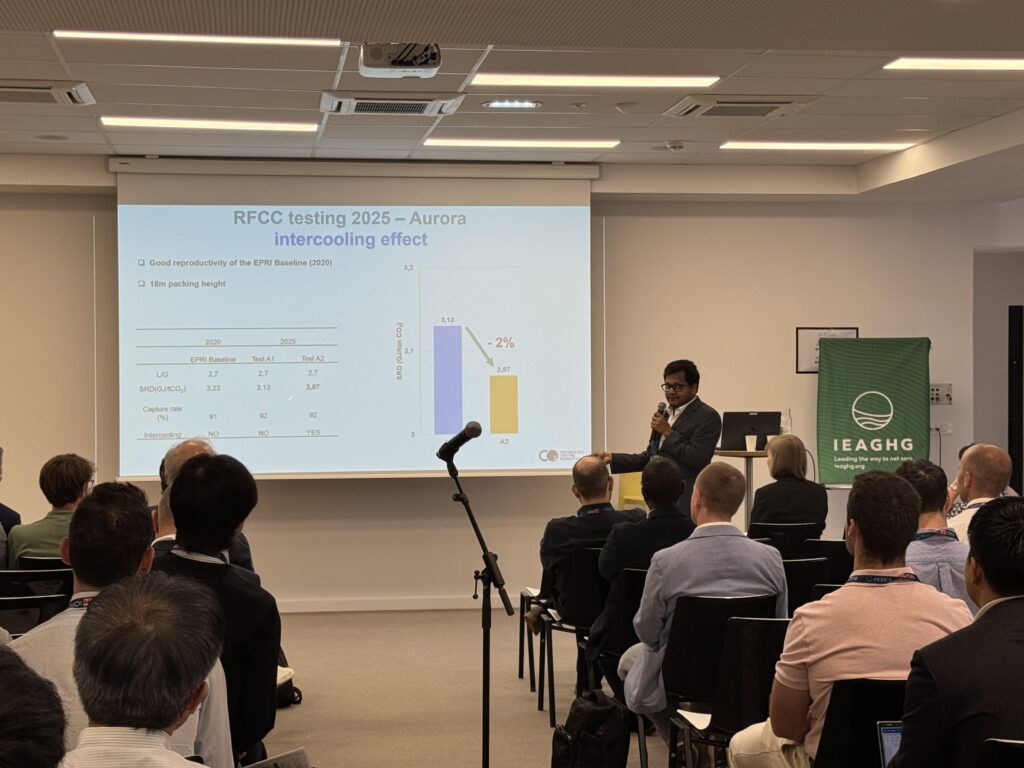

Large-Scale Testing with CESAR 1

In one presentation, Industrial Scale Carbon Capture Technology Testing at Technology Centre Mongstad: Results using CESAR 1, TCM’s Koteswara Rao Putta presented results from large-scale testing of the CESAR 1 solvent. With global CO2 emissions continuing to rise—surpassing 40 billion tons in 2024—the need for proven and scalable capture solutions was underlined.

“Amine-based capture technologies remain at the forefront of carbon mitigation strategies,” said Putta. “At TCM, our mission is to systematically test, validate, and improve these systems so they can be deployed with confidence at commercial scale. By doing so, we help reduce technical, environmental, and financial risks for industry.”

The CESAR 1 campaigns at TCM provided crucial data for industry partners and research institutions alike, supporting the scale-up of capture systems from pilot to industrial demonstration. These efforts formed part of wider European collaborations, such as the AURORA project, aimed at bridging the gap between laboratory innovation and full-scale deployment.

A complementary presentation by Ahmad Wakaa focused on detailed learnings from more than 6,000 hours of CESAR 1 testing in 2020, including thermal reclaiming and emission monitoring during RFCC flue gas operations. The results demonstrated high efficiency in removing degradation products, metals, and heat-stable salts, with minimal solvent loss and strong capture performance.

“By combining operational experience with in-depth solvent analysis, we are able to document both the robustness and the limitations of advanced solvents like CESAR 1,” explained Wakaa. “This knowledge is vital for operators who plan to run capture plants reliably and sustainably over long periods.”

Machine Learning for Smarter Emissions Monitoring

The presentation, Exploring Predictive Emissions Monitoring of Ammonia at TCM Carbon Capture Plant Using Open-Source Machine Learning Libraries, was delivered by Fred Rugenyi. This work explored how advanced data analytics can improve environmental performance by predicting solvent-related emissions, such as ammonia.

Using TCM’s extensive historical datasets and machine learning tools like Sci-kit Learn, the study compared different regression models to forecast emissions. The Random Forest model delivered the most accurate predictions, opening the door for smarter monitoring and mitigation strategies in real-world operations.

“Machine learning provides us with a powerful tool to understand complex plant behaviour,” noted Rugenyi. “By predicting emissions, operators can take preventive action to reduce environmental impacts while improving plant reliability.”

Together, these presentations underscored TCM’s role as a global testbed for carbon capture innovation, advancing both process technology and digital solutions that will be vital for achieving net-zero ambitions.

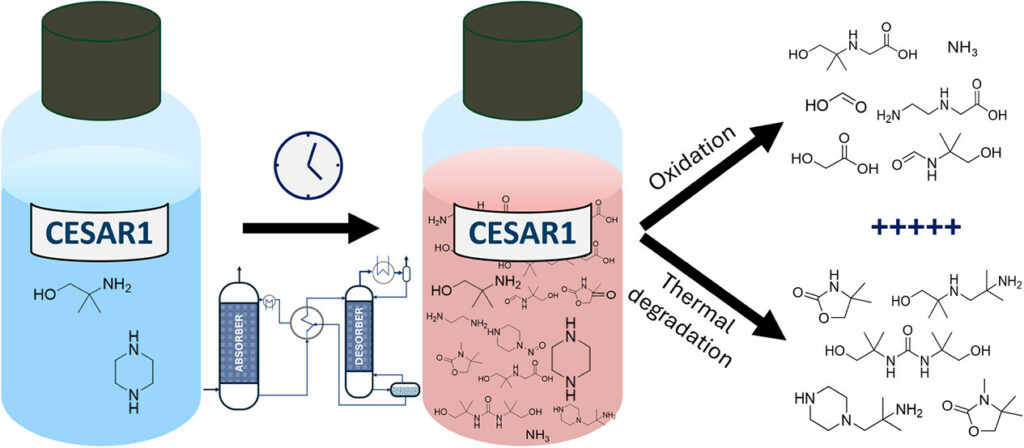

New Study Reveals What Happens to CESAR1 During CO₂ Capture

A recent scientific study provides new insights into how the promising CO2 capture solvent CESAR1 degrades under industrially relevant conditions.

CESAR1, a blend of 2-amino-2-methylpropanol (AMP) and piperazine (PZ), was originally developed in the EU project CESAR and has since been widely tested, including at the Technology Centre Mongstad (TCM). It has shown strong performance with lower energy use and higher stability than traditional benchmark solvents such as monoethanolamine (MEA).

The study, led by Vanja Bruvik from SINTEF, investigated degradation pathways of CESAR1 under oxidative and thermal stress. Using advanced liquid chromatography and mass spectrometry, the researchers identified and quantified 48 different degradation compounds, including 15 that had not previously been reported for AMP, PZ, or CESAR1.

Investigating How CESAR1 Breaks Down

One key finding is that CESAR1 degrades more rapidly than its individual components, with oxidative degradation proving to be the most critical factor. Compounds such as formic acid, formaldehyde, and N-nitrosopiperazine were detected under oxidizing conditions, while several other degradation products were formed at elevated temperatures. Importantly, some degradation pathways observed in laboratory tests correspond closely to results from pilot-scale operation at TCM, strengthening the relevance of the findings for industrial application.

“Understanding how solvents change over time is essential for safe, cost-effective, and environmentally sound CO2 capture. Our work provides important knowledge that can be used to optimize solvent management strategies, including how to monitor degradation and when to carry out solvent reclamation.”

Vanja Bruvik, Research Scientist at SINTEFFrom Laboratory to Large-Scale Testing

At TCM, CESAR1 has been tested extensively under real flue gas conditions, and the new results contribute directly to ongoing projects focused on emission monitoring and solvent stability.

“By combining laboratory research with large-scale testing, we build the knowledge base needed to ensure that next-generation solvents like CESAR1 can be deployed at full scale.”

Karen Karolina Høisæter, Senior Research Scientist at TCMAs the global need for CO2 capture grows, studies like this help pave the way for more robust and sustainable technologies that can play a crucial role in reaching climate targets.

President of the Storting Learned About Carbon Capture

On Thursday, 21 August, the Technology Centre Mongstad (TCM) welcomed a distinguished visitor once again: Masud Gharahkhani, President of the Storting and holder of Norway’s second-highest public office after the King, arrived at the facility.

Masud Gharahkhani came to learn more about CO2 capture, and there could hardly have been a better guide than TCM’s managing director, Ismail Shah.

Accompanying the President were Rune Bakervik from Bergen and Kamilla Bjerkholt Kleppe from Fedje, who are second and seventh on the Labour Party’s candidate list in Hordaland for the upcoming parliamentary election on September 8. Also present were Acting Mayor of Alver, Nina Bognøy, and Deputy Mayor of Austrheim, Per Lerøy. In addition to the TCM hosts, Equinor Mongstad was represented by Senior Manager for Asset Development & Climate, Sissel Nepstad, and Greenspot Mongstad by Project Manager, Einar Vaage.

TCM Crucial for Technology That Works

During the visit, Ismail Shah explained the fundamentals of CO2 capture and underlined the role TCM has played in testing and verifying capture technologies that are already in use — or soon will be — at full-scale plants both in Norway and abroad.

“Both of the capture facilities that are part of the Longship project use technologies we have tested. The capture plant at Heidelberg Materials’ cement factory in Brevik started in June, and a similar one will be coming at Hafslund Celsio’s waste-to-energy plant at Klemetsrud. But we must continually improve the technologies and reduce the costs of CCS in order to accelerate deployment. This is what we work on every day at TCM,” Shah emphasized.

Impressed by What He Saw

The President of the Storting was enthusiastic about what he learned.

“This has been very educational! I have long understood the important role TCM plays in addressing climate challenges both nationally and internationally but experiencing the operations ‘live’ makes an impression that strengthens this understanding. I’m cheering for you!”

Gharahkhani also highlighted the potential impact of TCM’s expertise in reducing local CO2 emissions at Mongstad. He stressed that with an active industrial policy and long-term framework conditions, industry can gain the predictability it needs to make the necessary climate investments.

After presentations and discussions in TCM’s administration building, the President of the Storting and his delegation were given a guided car tour of the test centre and refinery before continuing on to Knarvik for further engagements.

First Immigrant to Lead the Storting

Both TCM’s leader, Ismail Shah, and the President of the Storting share an immigrant background. In 1987, at the age of five, Gharahkhani fled Tehran, Iran, with his family, where his father had been a well-known politician. After time in an asylum reception centre, the family settled in Skotselv, Øvre Eiker, Buskerud.

After completing secondary school, Gharahkhani trained as a radiographer and worked at Blefjell Hospital in Kongsberg and Rjukan. His political career began in the Buskerud County council before he became the Labour Party’s group leader in Drammen’s city council. In 2017, he became a permanent Member of Parliament, and four years later he was elected President of the Storting — the first person with an immigrant background to hold the position.

Carbon Capture: A Key Driver of Green Industrial Growth at Mongstad

Carbon capture and storage (CCS) could stimulate the development of existing and new industries at Mongstad.

With world-leading expertise at the Mongstad Technology Centre (TCM) and ambitious plans for industrial transformation, the region is facing a turning point that could define its industrial future.

Together with TCM, Greenspot Mongstad organized a meeting during Arendalsuka on how zero emissions can become a reality in Norwegian industry. Mongstad’s industrial sector alone accounts for approximately 3.5 percent of Norway’s total CO2 emissions. In his presentation, project manager Einar Vaage outlined ongoing initiatives to tackle this major challenge.

The Industrial Park – A National Heavyweight

Mongstad Industrial Park currently hosts 3,500 full-time positions across 63 companies, primarily in oil- and gas-related operations. It serves as the supply hub for 23 offshore platforms in the North Sea. Behind these large numbers, however, lies a challenge: Equinor Mongstad emits around 1.6 million tonnes of CO2 annually – equivalent to 3–3.5% of Norway’s total emissions.

According to Vaage, the solution is to renew the industry and create new activity that both secures jobs and reduces the climate footprint.

Two Priorities for Green Transformation

Vaage highlighted two main initiatives that could reshape Mongstad in the coming years:

- Refinery Optimization – Increase competitiveness while reducing CO2 emissions.

- New Primary Industries:

- Steel pellet production from ore using gas as a reducing agent, combined with CCS.

- Sustainable aquaculture – land-based salmon farming with a capacity of 2,000 tonnes of smolt and 43,000 tonnes of market fish, scheduled to start in 2028.

- SAF (Sustainable Aviation Fuel) – production of sustainable jet fuel using residual waste as feedstock.

Linked to these new industries, we are already seeing development and establishment of both new and existing supplier environments.

CCS – The Glue That Binds the Industry

According to Vaage, carbon capture and storage is absolutely essential for a successful transformation.

The plan is to increase the concentration of CO2 at Mongstad by attracting industries such as steel production and SAF, which will contribute millions of tonnes of CO2. This will make it economically viable to build a pipeline to the Smeaheia field in the North Sea – both to manage current emissions at Mongstad and to transport CO2 from other regional actors.

“To address today’s emissions, we actually need more CO2 – which is why the expertise offered by TCM is so incredibly important,” Vaage emphasized.

Strong Political Signals

During the subsequent debate, both the acting mayor of Alver, Nina Bognøy, and the county mayor of Vestland, Jon Askeland, voiced their support for the plans.

Bognøy recalled Mongstad’s history: “It’s been 50 years since we forcibly emptied a village of its people. We cannot abandon Mongstad now. We owe it to the community to secure new industries there – which is also important for the region and for the country.”

Askeland highlighted Norway’s opportunity to lead: “The bigger you are, the more you must do, and those with the most must contribute the most. Norway has the knowledge and resources to take the lead. TCM is an international star, and the Mongstad refinery has already contributed to emissions reductions multiple times through the delivery of flue gas to TCM and ongoing technology development.”

He expressed a strong desire for faster action: “We are close to large storage reservoirs in the North Sea. I hope we can soon link TCM and the refinery so that we can eliminate greenhouse gas emissions once and for all.”

A Turning Point for Mongstad

With a combination of established industry, new green technologies, and political will, Mongstad could become a hub for green transformation. CCS sits at the heart of this transition – not just as a climate tool, but as a prerequisite for creating new value.

If these plans are realized, Mongstad could, within the next decade, transition from an emissions source to a model for industrial climate solutions, both in Norway and internationally.

The Public Sector Must Demand CCS

About 100 participants boarded the “Vestlandsbåten” on 12 August at Arendalsuka, when Technology Centre Mongstad (TCM) and Greenspot Mongstad hosted presentations and debate on the future of CCS.

Arendal: – Almost half of the revenue generated by the Norwegian cement industry comes from public-sector purchasing. Although the government quarter and Bane NOR’s new workshop in Drammen are to be constructed using low-carbon cement, examples like these remain rare. At a recent Arendalsuka debate, speakers emphasised that public procurement must play a much stronger role in requiring products based on CCS.

What will it take for more Norwegian companies to invest in CCS?

Heidelberg Materials, Europe’s largest cement supplier, is also the first to join a complete CCS value chain through the capture facility launched at its Brevik plant in June, as part of Norway’s national Longship CCS initiative.

Pia Prestmo, the company’s Public Affairs Manager, was clear about the public sector’s responsibility:

“Whether it is cement, steel, or fertilizer, the financial viability of low-carbon solutions must be strengthened. Boardrooms are waiting for one signal — that the risk is low enough to justify building a facility in their sector. They need assurance that climate-friendly products will become standard goods.”

Requires Billions in Government Support

“CCS is absolutely necessary to avoid catastrophic global warming,” emphasized Eivind Berstad, head of the CCS team at Bellona. “This is the technology that is hardest to replace, so we are completely dependent on it. But CCS needs an extra push, which is why we are so focused on it.”

Berstad noted that momentum for CCS increased when the focus shifted from power generation to industry. “In Europe, there is now strong momentum to make it happen. Politically, a concrete strategy is being set, funding is being allocated, and oil and gas companies must commit to providing storage capacity.”

He argued that Norway lacks a framework for CCS development. “What is needed is billions in the state budget for carbon capture and storage. Authorities must ask industry about volumes so that infrastructure can be planned, and Norway must participate in the European effort requiring oil companies to provide storage capacity already by 2030.”

More Research and Development Needed

Kristine Karlstad, Vice President Sustainability at Hydro, noted that since 1991, the company has cut emissions by 55% while increasing production at its five Norwegian smelters by 40%. However, she explained that the CO2 content in exhaust gases from aluminium production is low, and effective capture technologies are not yet available.

“We have picked the low-hanging fruit, and now the hardest part remains. We must work with research and development, testing, and prioritization before we can implement CCS at our plants.”

Strong Collaboration Between SINTEF and TCM

SINTEF has been working on CCS solutions since 1986. Its Director of Sustainability, Nils Røkke, highlighted the value of its Trondheim test facility as a partner to TCM for near full-scale trials.

“You could have bought a car in 1900, but cars are undoubtedly better in 2025. The modern car could not exist without that history. Over the decades, we have reduced energy use in carbon capture by 25% and eliminated amine-related emission issues — proof of how strong collaboration between research and innovation has delivered full-scale solutions.”

Looking ahead, Røkke underlined the need for storage capacity, CO2 delivery systems, and transport solutions adapted to the North Sea’s temperature conditions. “In short,” he said, “we need workable specifications that balance risk and cost.”

Reducing Risk and Costs

Since its inception in 2012, TCM has tested 17 different technologies. Managing Director Ismail Shah noted that nearly all full-scale CCS plants built or approved worldwide have used technologies tested at TCM.

“For it to be cheaper for industry to capture CO2 than to release it, we must lower costs. That means advancing research, development, and demonstration in parallel with building more capture facilities. The more we build, the easier it becomes to find solutions that work across industries. Risk reduction must cover technical, environmental, and commercial aspects.”

Continued Government Commitment to TCM

State Secretary Astrid Bergmål from the Ministry of Energy praised TCM’s role: “The work at Mongstad to test, verify, and demonstrate CO2 capture technologies on a large scale is world-class and central to our CCS efforts.”

She emphasized that Longship is not the end of Norway’s CCS ambitions: “The government wants to facilitate the continued growth of the CCS market, where industry finds good commercial solutions. Any new policy instruments must be well-targeted and enable industry-driven solutions. That is what we are working on now.”

Bergmål added that the government is also working to find a solution for more commercial operation of TCM with reduced state support.

TCM Showcases CO₂ Capture Expertise at TCCS-13 in Trondheim

From June 17–19 nearly 500 carbon capture, transport, and storage (CCS) professionals from 31 countries convened in Trondheim, Norway, for the 13th Trondheim CCS Conference (TCCS-13).

As one of the field’s most prominent scientific events, the conference TCCS-13 offered a key platform for presenting cutting-edge research, exchanging knowledge, and discussing new projects across the CCS value chain. Technology Centre Mongstad (TCM) was once again well represented and made strong contributions throughout the conference.

Attending on behalf of TCM were Muhammad Zeeshan, Principal Researcher Environment/HSE, and the CO2 Capture Technologists Sundus Akhter, Dimitrios Siozos, and Ticiane Oliveira. Also present the operation shift Leader Kathrine Sætre, the laboratory engineer Karen Høisæter and the master student and current TCM intern Tochukwu Ogbu. In addition to attending various scientific sessions, the team actively contributed through oral and poster presentations and participated in co-authored work with leading research institutions.

TCM Research in the Spotlight

One of the conference highlights was the oral presentation by Muhammad Zeeshan and Sundus Akhter. We shared recent findings from our work at TCM on CESAR1 solvent chemistry. “We clearly noticed more people approaching us after the presentation, wanting to learn about our projects and even explore possible collaboration or visits to TCM,” said Zeeshan and Akhter.

Additionally, a poster authored by Tochukwu Ogbu and Muhammad Zeeshan on developments in LCMS lab methods attracted a great deal of interest. The TCM team also contributed as co-authors on several other presentations, including one on CESAR1 solvent reclaiming with collaboration with SINTEF as part of the ongoing Horizon Europe project – Aurora. Their involvement underscored the centre’s active engagement across both scientific and operational aspects of CCS.

Another oral presentation co-authored by 3 TCM members and delivered by UMONS university addressed the European funded MOF4AIR project results. TCM was one of the testing sites for the adsorbent-based technology producing valuable results in the field and drawing significant attention and led to increased interest in TCM’s work from other participants.

Importantly, TCM’s engagement extended beyond presenting. The centre was also represented in the conference’s peer-review process, with Zeeshan serving as a reviewer for several abstracts. This contribution reflects TCM’s trusted role in evaluating and shaping CCS research worldwide.

Contributing Beyond the Podium

Beyond the technical sessions, TCM participants used the opportunity to engage in valuable networking with researchers and industry experts from across the globe — including countries such as the UK, France, the UAE, and Austria. “There was strong representation from the Gulf countries this year, and it was encouraging to see growing CCS initiatives being developed in those regions,” noted Ticiane Silva de Oliveira.

TCM’s delegation also included employees from operations and the lab, highlighting the centre’s commitment to cross-disciplinary learning and continuous knowledge development.

In summary, TCCS-13 not only reaffirmed TCM’s position as a trusted voice in the global CCS community but also helped strengthen existing relationships and lay the groundwork for new partnerships and innovation in the years ahead.

Main photo: SINTEF