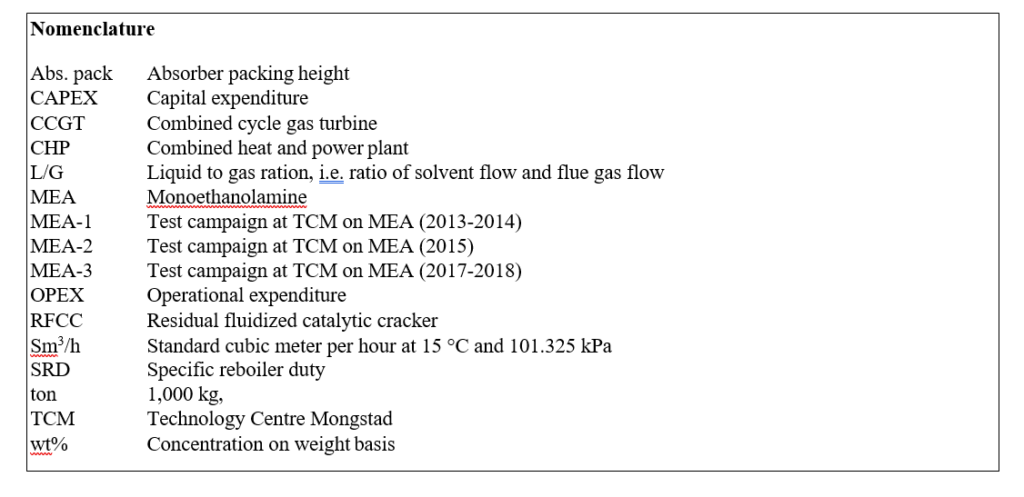

Development of CO2 capture process cost baseline for 555 MWe NGCC power plant using standard MEA solution (2022)

Koteswara Rao Puttaa*, Daniel Saldanab, Matthew Campbella, Muhammad Ismail Shaha

aTechnology Centre Mongstad, 5954 Mongstad, Norway

bAspen Technology, Inc, 01730 Bedford, Massachusetts, USA

Abstract

Carbon capture, utilization and storage (CCUS) is essential to achieve Net-zero emissions targets. The IEA sustainable development scenarios also emphasize the importance of CCUS. Post-combustion CO2 capture using amine solvents is the most mature technology among several options available and amine-based CO2 capture projects have been demonstrated at industrial scale. Several new vendors and technology developers are working on multiple innovative and advanced CO2 capture concepts. Industrial clients, project developers targeting the CO2 capture projects in their facilities require reliable and updated costing information using non-proprietary solvents to develop investment strategies, portfolios and evaluate the commercial project bids for CO2 capture.

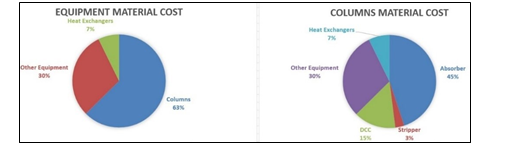

The CO2 project cost estimation depends on several factors like solvent used, amount of flue gas treated, accuracy of the simulation tool/model used for designing the CO2 capture plant, quality and size of experimental pilot data used for model validation, accurate representation of the capture facility while keeping the columns hydraulics suitable for practical operation, consideration of space requirements for column internals, design of plate heat exchangers and other packaged items like filter package and reclaiming units. Domain knowledge and practical operational experience are also crucial to perform the study. Selection of appropriate material of construction also plays a key role in accuracy of cost estimation. Technology Centre Mongstad’s 10 years of operational knowledge and experience together with AspenTech’s expert team worked together to perform a reliable and accurate costing exercise by considering all essential elements of CO2 capture process and project. The key finding from the current costing baseline study are columns material costs found to account for 63% of total CO2 capture process equipment material costs and absorber alone accounts for 45% of these total equipment material costs. The total capital expenditure for capturing 90% CO2 from 555 MWe Natural Gas Combined Cycle (NGCC) power plant using aq. 30 wt% MEA solvent is estimated to be around 326.6 Million USD. Annual total operating costs are estimated to be 47 Million USD. Assuming 25 years of plant life, the cost of CO2 capture is calculated to be 47 USD/ton.

1. Introduction

The CO2 Technology Centre Mongstad (TCM) is located next to the Equinor Mongstad refinery in Norway. TCM DA is a joint venture owned by Gassnova representing the Norwegian state, Equinor, Shell, and TotalEnergies. TCM is the largest post-combustion CO2 capture (PCC) test centers in the world. This facility has been in the operation from 2012 and is often called the “amine plant”.

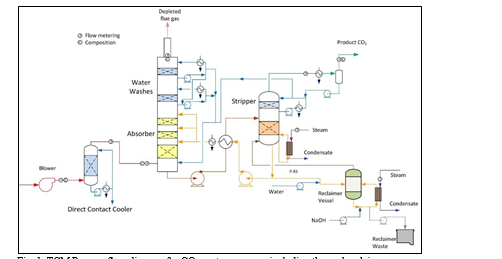

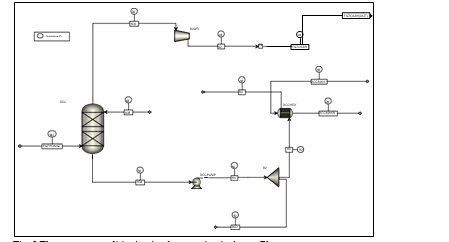

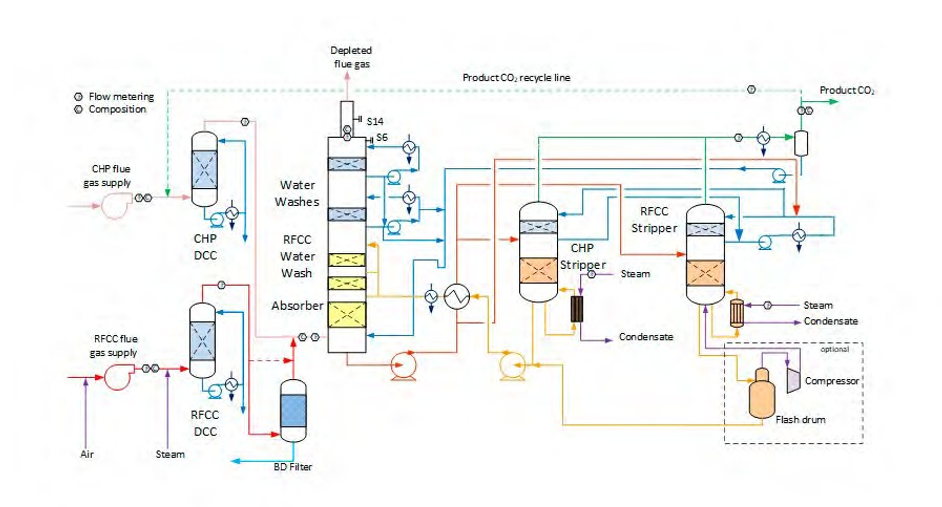

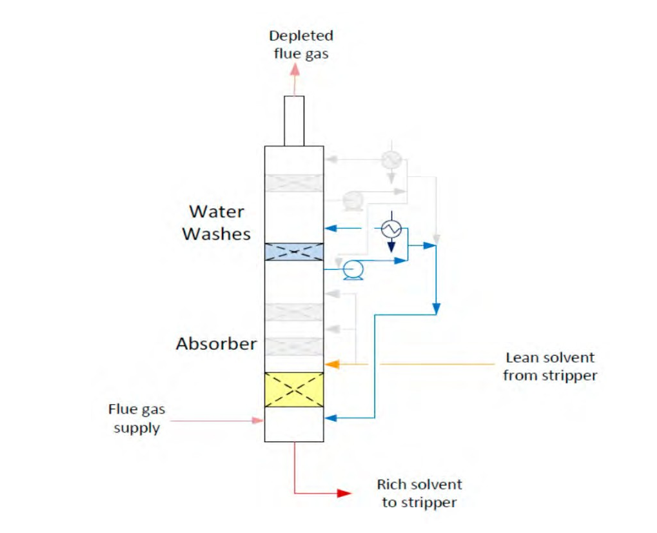

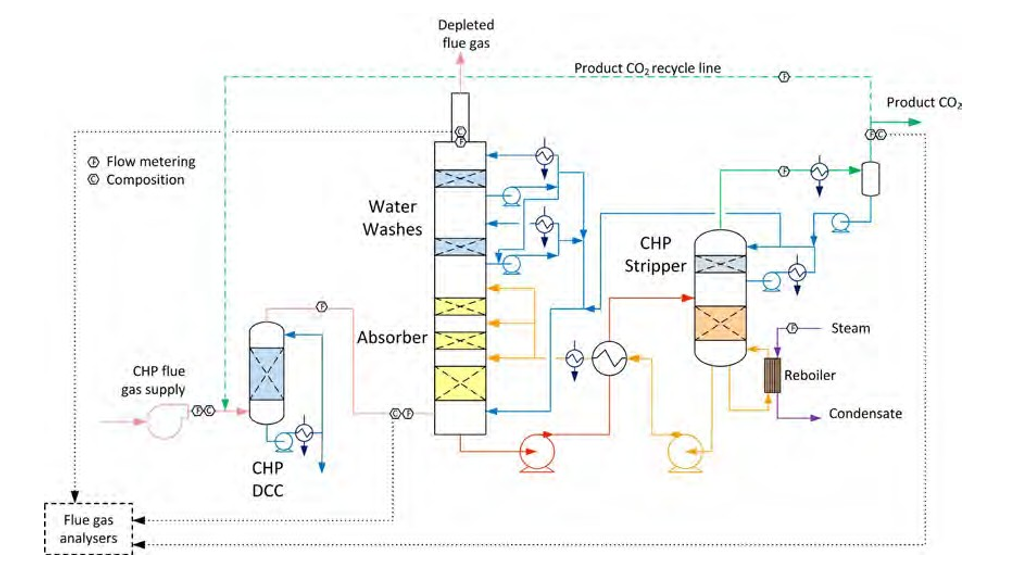

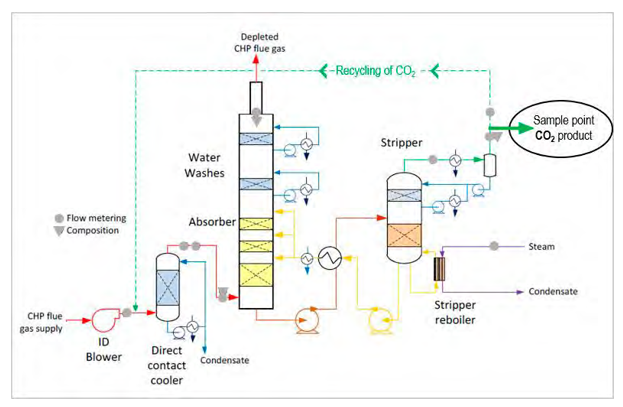

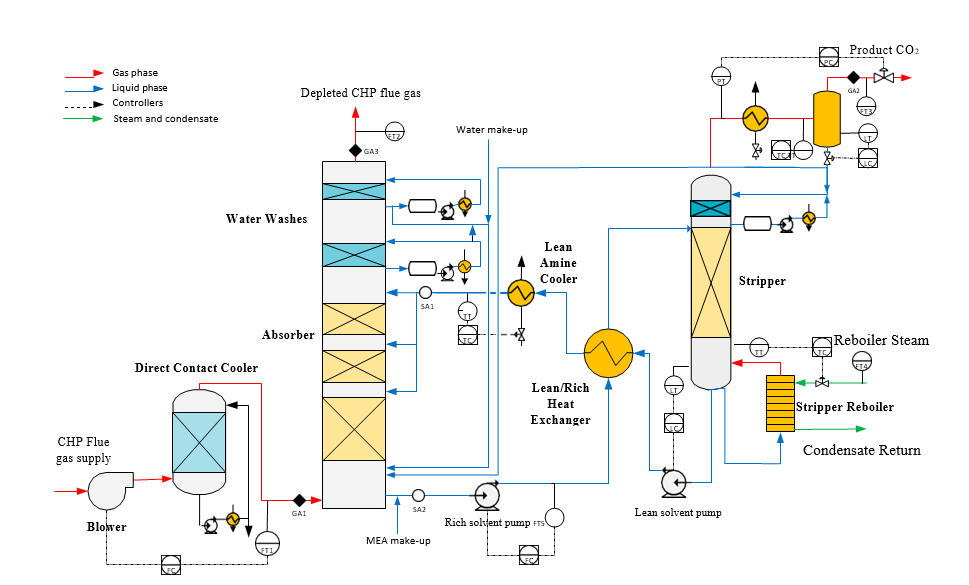

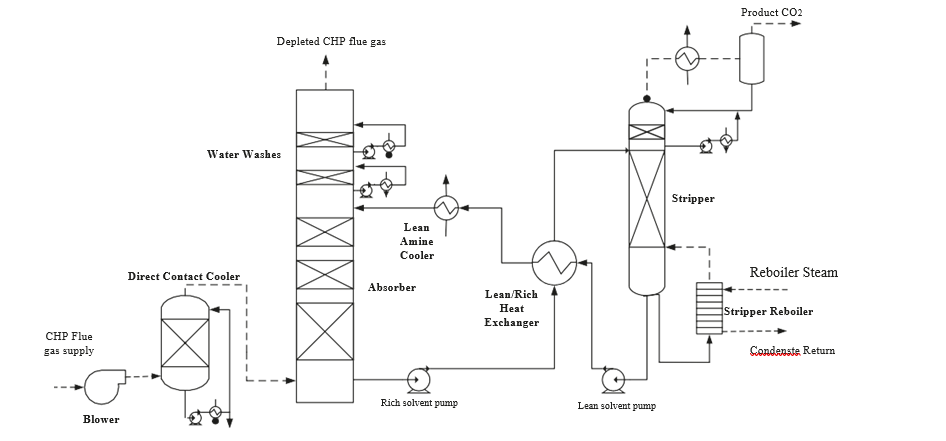

TCM amine plant was built to run on two different types of flue gases, namely, natural gas-fired combined heat and power (CHP) plant i.e., CHP flue gas is from a natural gas fired CCGT plant or the Equinor Mongstad refinery residue fluid catalytic cracker (RFCC). Over the last 10 years, several commercial vendor proprietary solvents as well as non-proprietary solvents have been tested at TCM amine facility. TCM amine plant is well equipped with around 4,000 online sensors to gather critical information in addition to more than 100 offline manual sampling points. TCM has more than 20,000 hours non-proprietary operational data using aqueous monoethanolamine and CESAR 1 (AMP/PZ mixture) [1–7]. Fig. 1 shows the process flow diagram for CO2 capture process at TCM.

A comprehensive baseline for performance and cost estimation of CO2 capture processes is crucial to assess, identify and support widespread deployment of CO2 capture projects. Successful CCUS (Carbon Capture Utilization and Storage) projects will be essential for achieving world Net-Zero emissions targets by 2040-2050. To have a fair assessment of new technology developments and avoid using commercial technology as baseline, TCM has developed a cost baseline using a non-proprietary solvent, i.e., aqueous 30 wt% Monoethanolamine (aq. MEA) solution. The assessment of performance and cost were determined independently and does not represent the views of any technology vendor. The baseline input conditions for this model and costing exercise were based on National Energy Technology Laboratory (NETL) baseline study case 14 [8] with CO2 capture.

The present work discusses about the systematic methodology or steps followed to develop a technoeconomic analysis (TEA) for CO2 capture technology using AspenTech products like Aspen Plus, Aspen EDR, Aspen Capital Cost Estimator (ACCE). A proper costing baseline development must contain five critical steps, given below:

Step 1: Develop and validate an accurate rate-based process model with operational data from pilot plant Step 2: Run steady state simulation with aqueous 30 wt% MEA solvent targeting 90% CO2 capture from the industrial plant of interest and capacity

Step 3: Perform detailed sizing of major process equipment such as columns (direct contact cooler, absorber, regenerator, water-wash sections) and heat exchangers, pumps, blower/compressors …etc.

Step 4: Perform estimation of costs using vendor quotes and/or relevant costing software tools by considering all relevant elements

Step 5: Economic/financial analysis and presentation of results and sensitivity study

These steps are described in detail in the following sections 2 and 3.

2. Methodology

As mentioned above, a proper technoeconomic analysis for CO2 capture technology using alkanolamines requires five essential steps explained below.

In the present work, CO2 capture using aqueous MEA solution has been considered and AspenTech software tools are used to perform different steps involved in the TEA. In this section, Steps 1- 4 will be described in detail and step 5 will be presented in section 3.

2.2 Step 1 – Development and validation of process model

In order to develop the process model, it is important to understand the chemicals used, chemistry involved and phenomena occurring in the process. Thermodynamics plays key role in CO2 absorption process design and simulation as the absorption with chemical solvents requires thermodynamic data, especially phase equilibria: vapor-liquid equilibrium (VLE) and speciation in the solution. Aqueous amine systems used for CO2 capture are non-ideal systems which can be thermodynamically modelled utilizing activity coefficients models for the liquid phase such as Electrolyte NRTL (e-NRTL), Extended-UNIQUAC or similar. Gas phase is modelled by utilizing equation of state such as Redlich-Kwong (RK) or Soave-Redlich-Kwong (SRK). Aspen Plus V11 software is used to develop the model and validate.

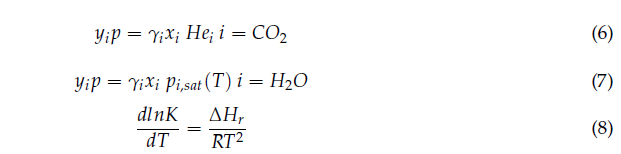

In the current study, MEA is the main chemical used as solvent to capture the CO2 from flue gas. In the present study, e-NRTL RK method has been chosen for thermodynamic modelling. The chemistry/ chemical equilibrium involved in the MEA-CO2-H2O system are given by the reactions (1)-(5) below [9,10].

Ionization of water:

2H2O ↔ OH− + H3O+ (1)

Dissociation of carbon dioxide:

2H2O + CO2 ↔ H3O+ + HCO3− (2)

Dissociation of bicarbonate:

H2O + HCO3− ↔ H3O+ + CO32− (3)

Dissociation of protonated amine:

MEAH+ + H2O ↔ H3O+ + MEA (4)

Carbamate reversion to bicarbonate:

𝑀𝐸𝐴𝐶𝑂𝑂− + 𝐻2𝑂 ↔ 𝑀𝐸𝐴 + 𝐻𝐶𝑂3− (5)

In the literature, simulation or design of columns is performed by either using equilibrium-based approach or rate- based modelling approach. For CO2 capture applications with amine solvents, rate-based modelling approach gives a more realistic and predictive model compared to equilibrium-based approach. Rate-based modelling approach has been used for all columns in the CO2 capture.

In addition to the reactions (1)-(5) considered in equilibrium thermodynamic model above, kinetic reactions are also important to accurately design and simulate the process, especially absorber column. Two reactions have been considered to be kinetically controlling, given below [9,11,10]:

𝐶𝑂2 + 𝑂𝐻− ↔ 𝐻𝐶𝑂3− (6)

𝐶𝑂2 + 𝑀𝐸𝐴 + 𝐻2𝑂 ↔ 𝑀𝐸𝐴𝐶𝑂𝑂− + 𝐻3𝑂+ (7)

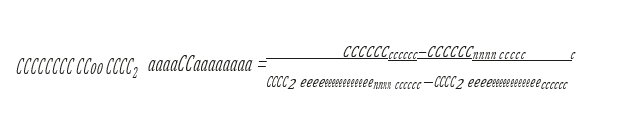

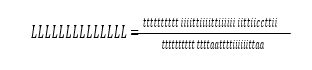

Power law expressions are used for the rate-controlled reactions (reactions (6)- (7)) on activities basis. The power law expression (8) is used for reaction rate:

Where 𝑟 represents reaction rate; 𝑘 is pre-exponential factor; 𝐸 is activation energy; 𝑅 is Universal gas constant; 𝑥𝑖 is mole fraction of component i; 𝛾𝑖 is activity coefficient of component i; 𝜗𝑖 is the stoichiometric coefficient of component i in the reaction equation and T is temperature. Kinetic reaction parameters are regressed using literature kinetic data.

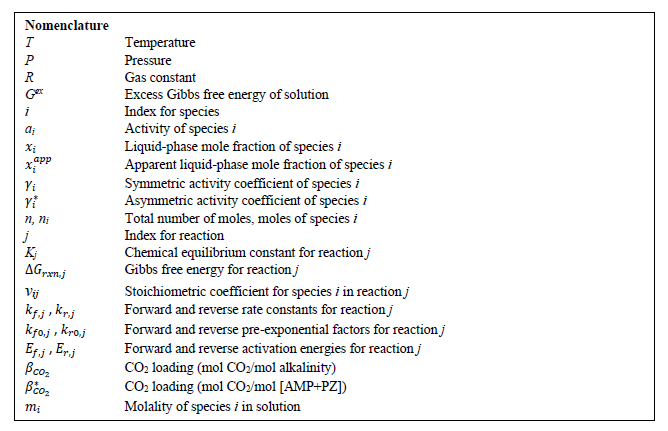

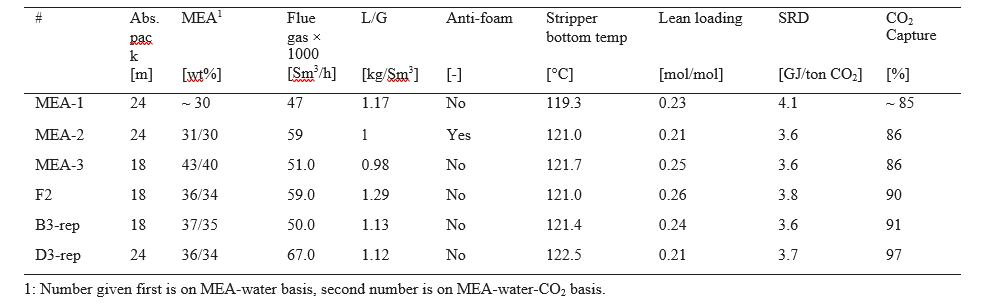

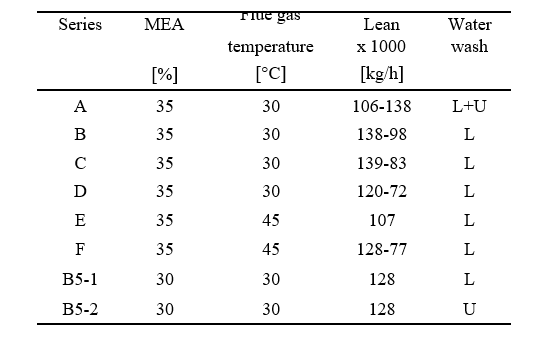

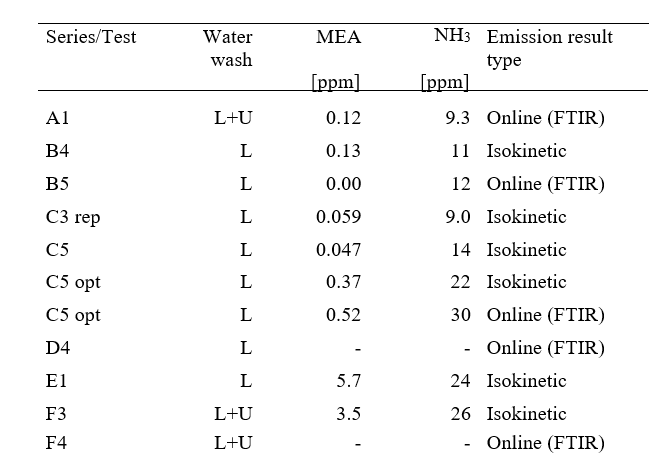

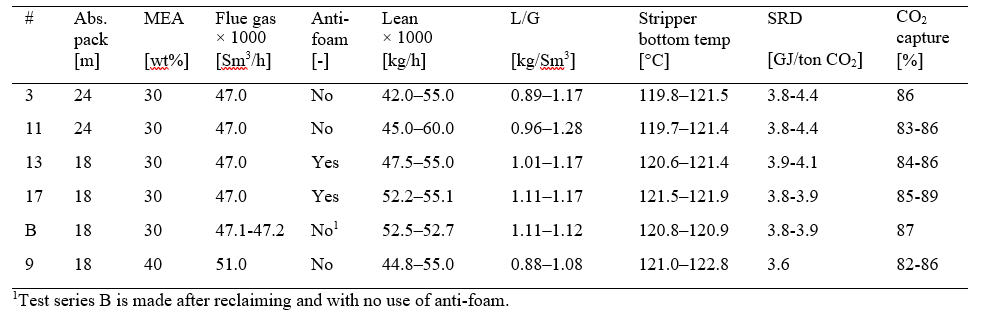

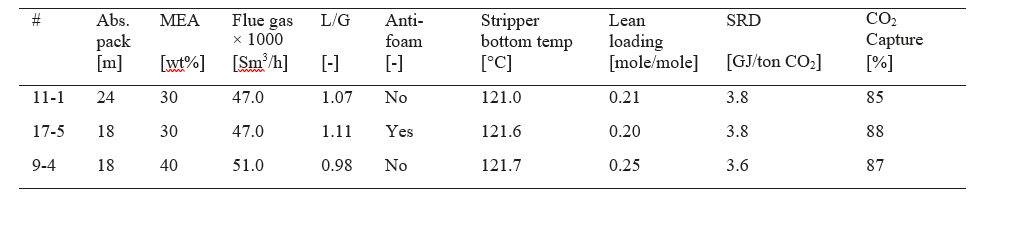

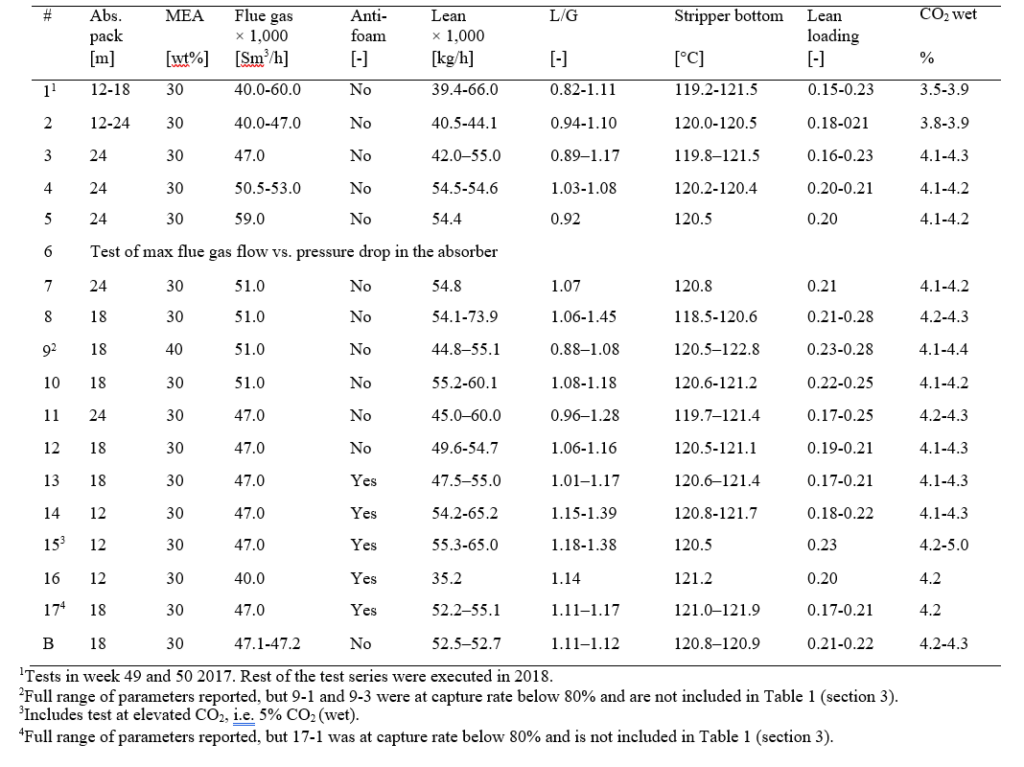

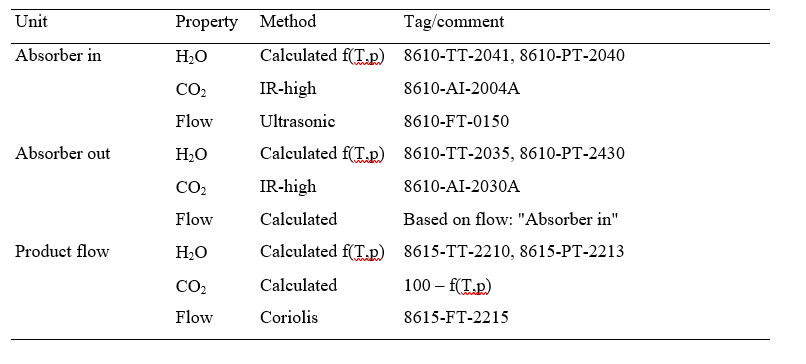

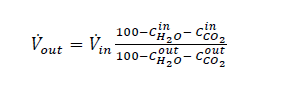

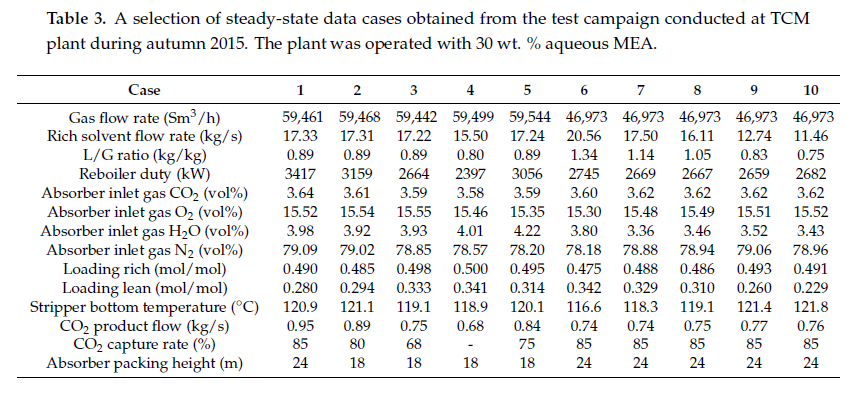

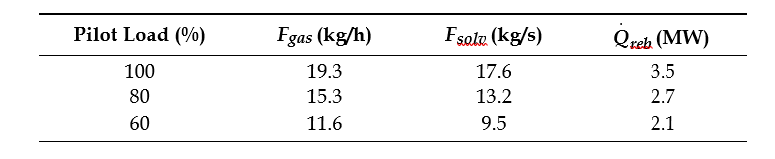

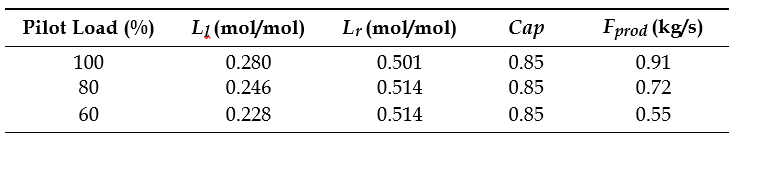

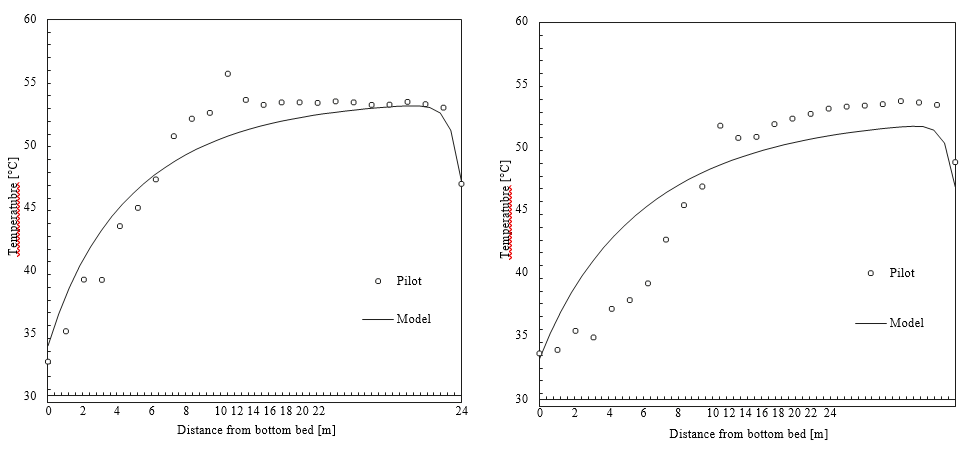

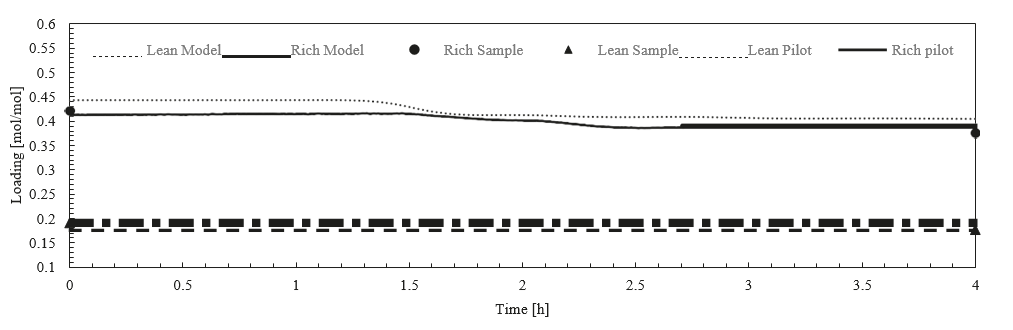

After the development of the e-NRTL RK thermodynamic model for MEA-CO2-H2O system and kinetic parameters refinement to match literature data, this model is validated with TCM testing pilot scale data. This validation has been performed by implementing TCM amine plant in Aspen Plus and collecting the steady state operational data over wide range of conditions. The operating conditions window used for the model validation is given in Table 1. The criteria for selection of steady state conditions employed in model validation are as follows:

- Overall plant mass balance is 100 +/- 2%

- CO2 mass balance 98 +/- 2%

- Stable operation at least 2 – 6 hours (steady state operation)

- Availability of liquid lab analysis results for CO2 and amine concentrations

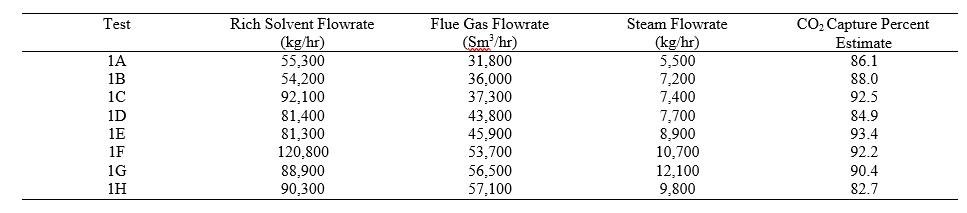

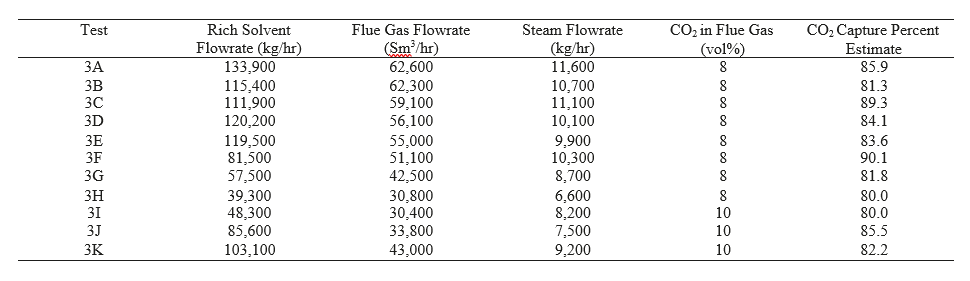

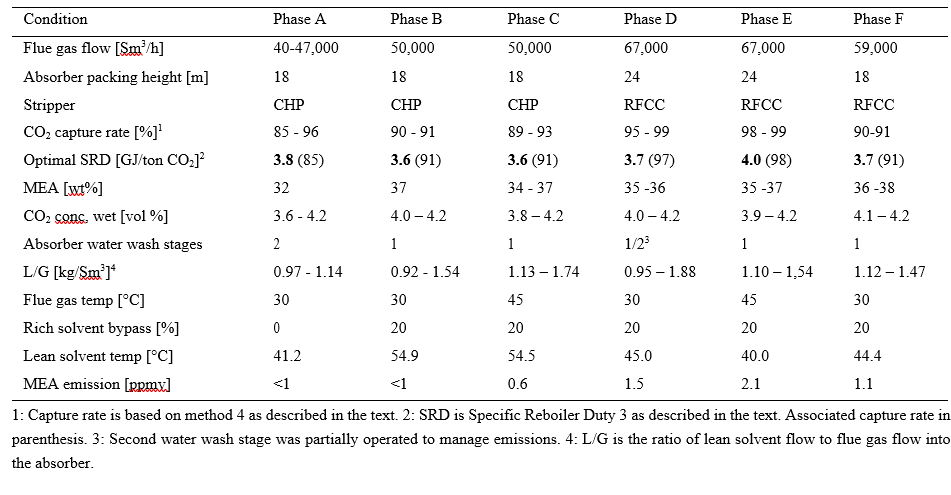

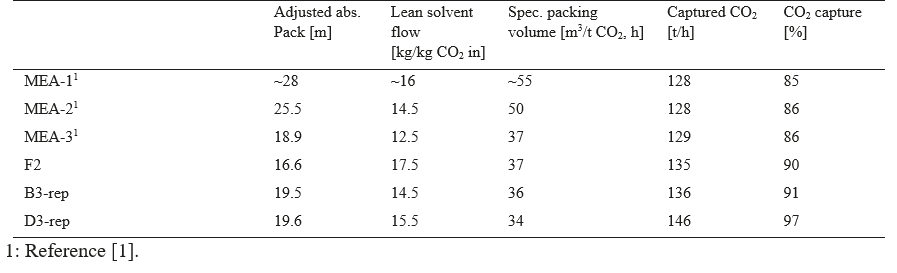

Table 1 TCM Aspen Plus model validation conditions range for CO2 capture using aq. MEA solution

| Operating parameter | units | Range |

| Flue gas flowrate | Sm3/hr | 34,000 – 68,000 |

| Flue gas CO2 concentration | vol % | 3.6 – 14 |

| Flue gas temperature | oC | 28 – 45 |

| MEA concentration | wt % | 28 – 40 |

| Lean amine loading | mol/mol | 0.1 – 0.3 |

| Lean amine temperature | oC | 35 – 50 |

| CO2 capture rate | % | 70 – 99 |

| Absorber packing height | m | 12,18, 24 |

| Water wash sections | # Sections | 1, 2 |

| Stripper in operation | – | CHP, RFCC† |

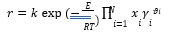

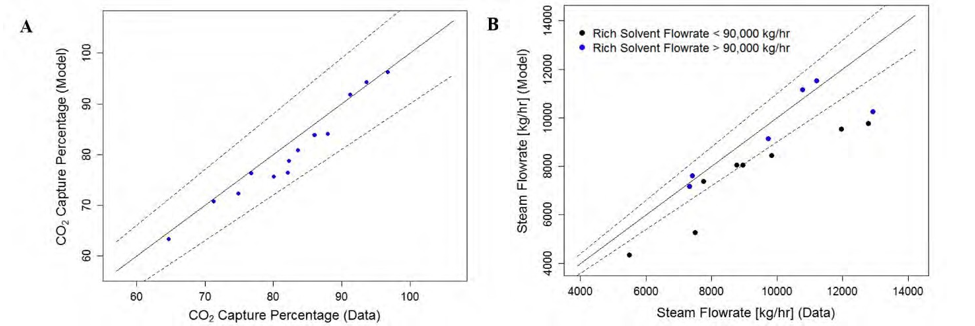

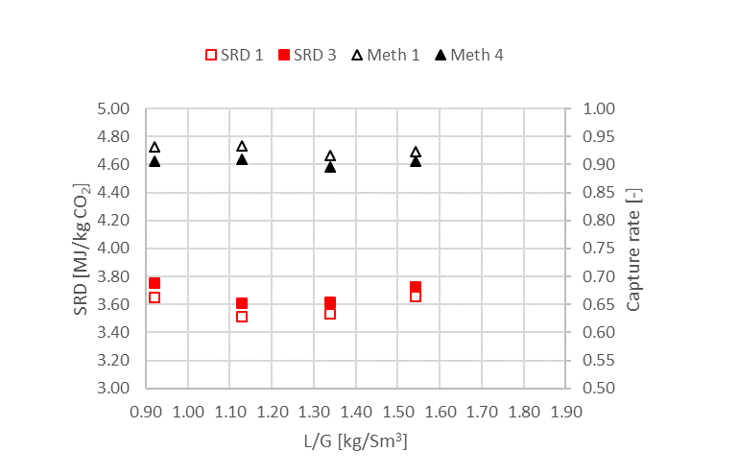

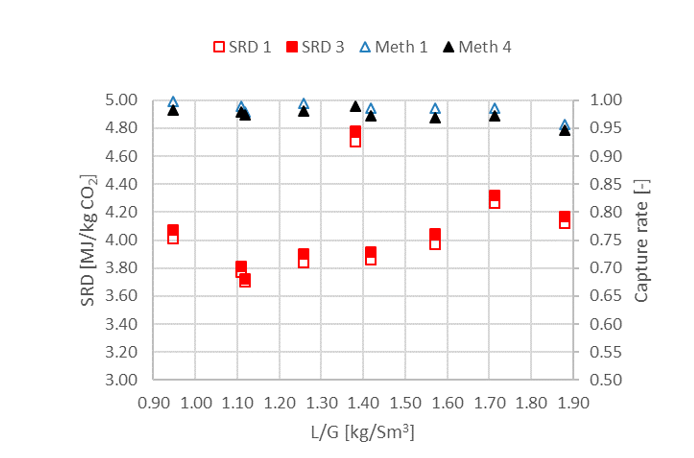

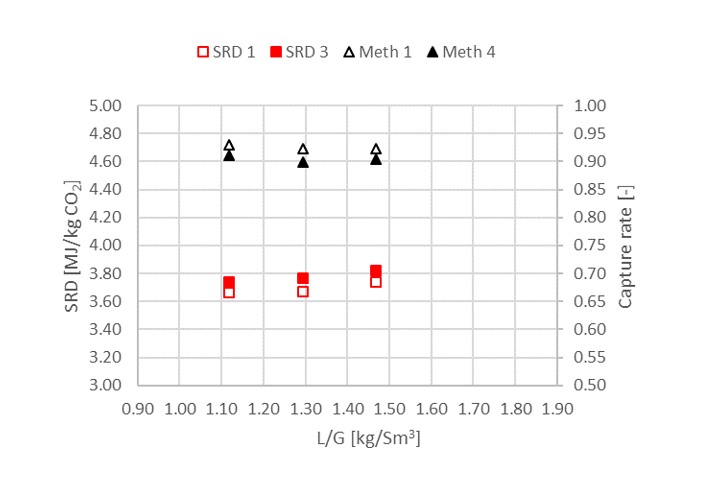

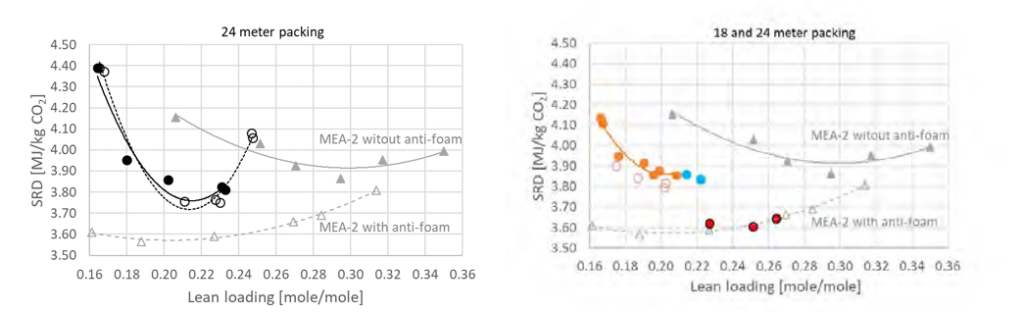

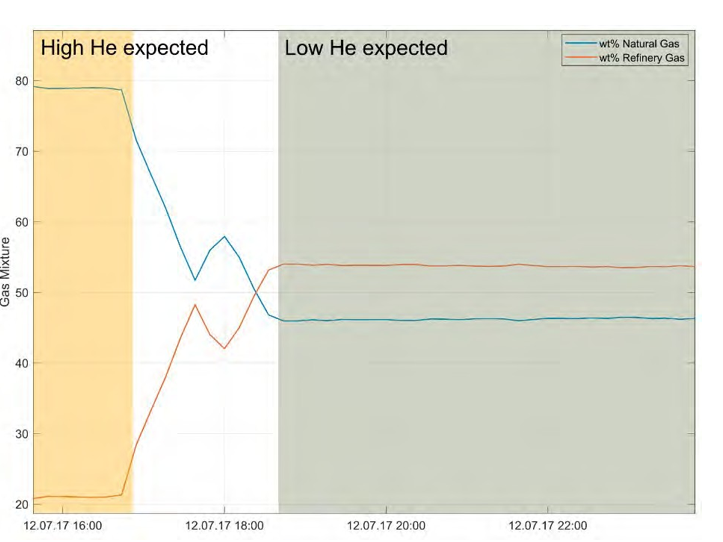

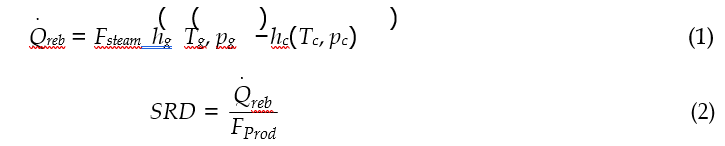

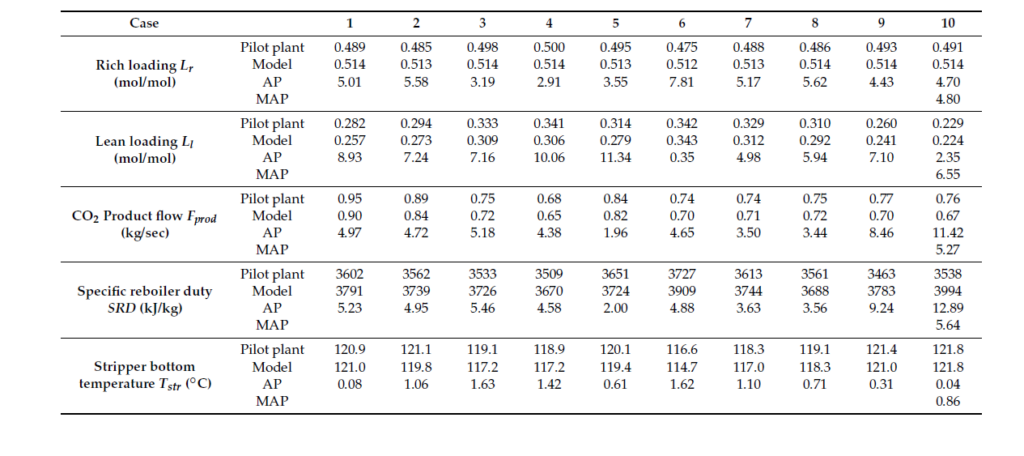

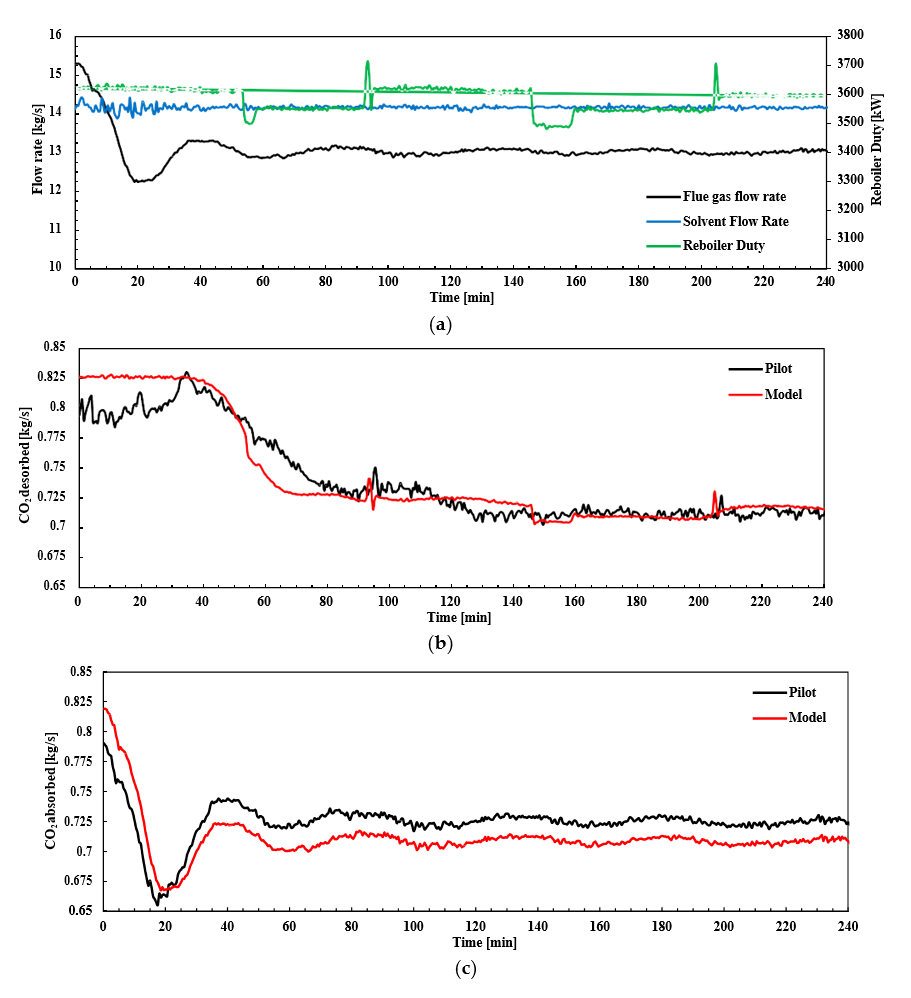

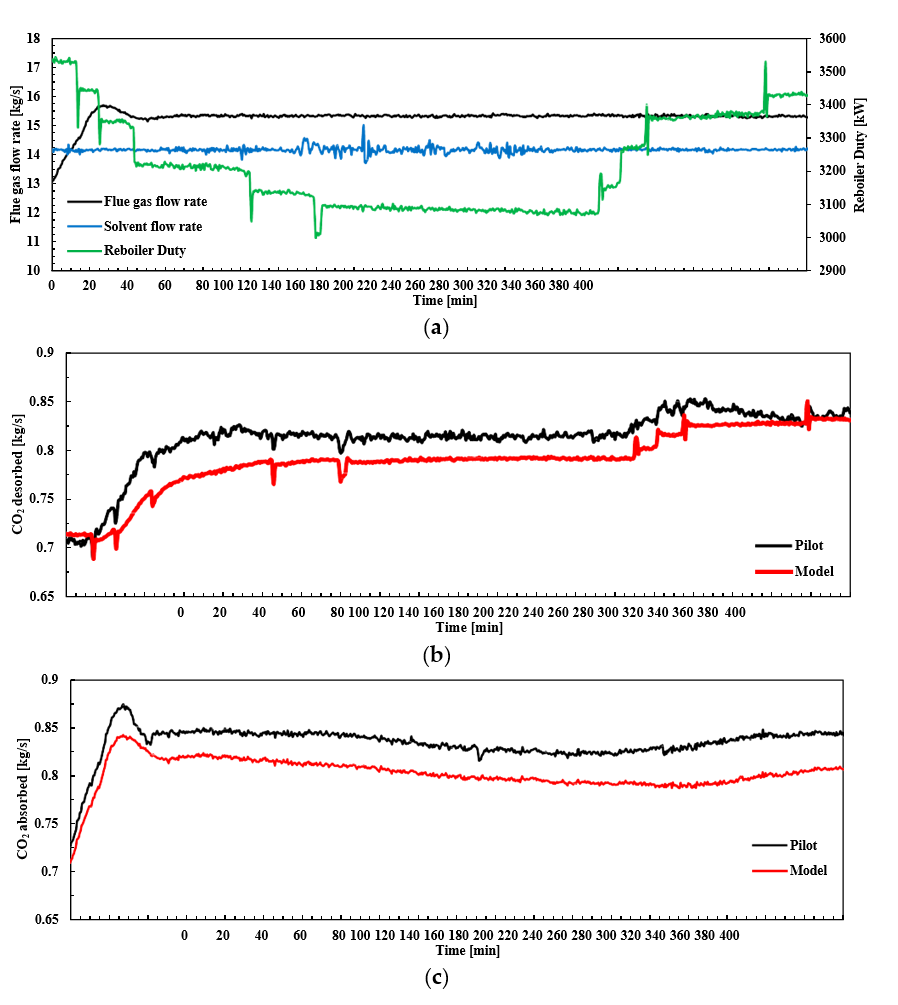

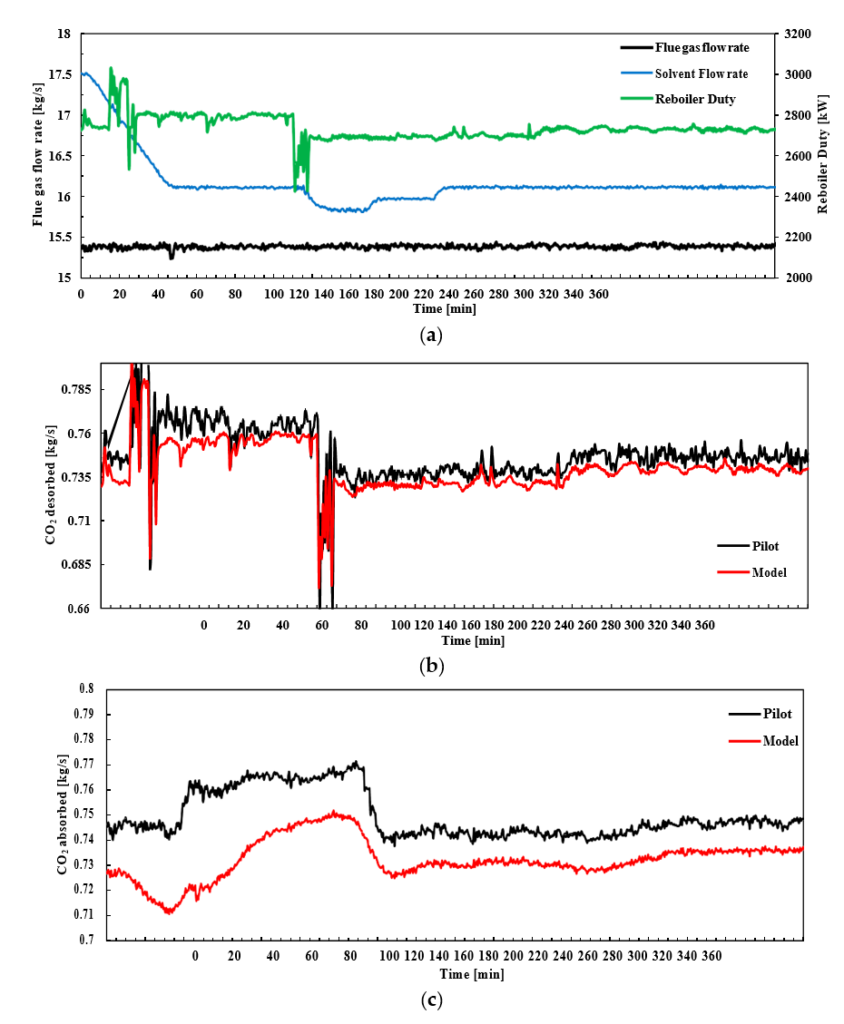

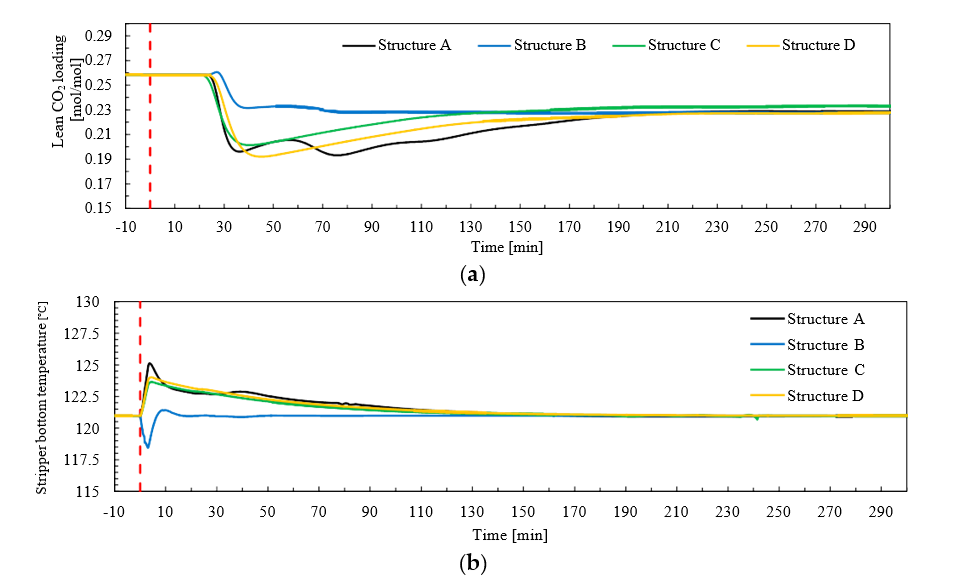

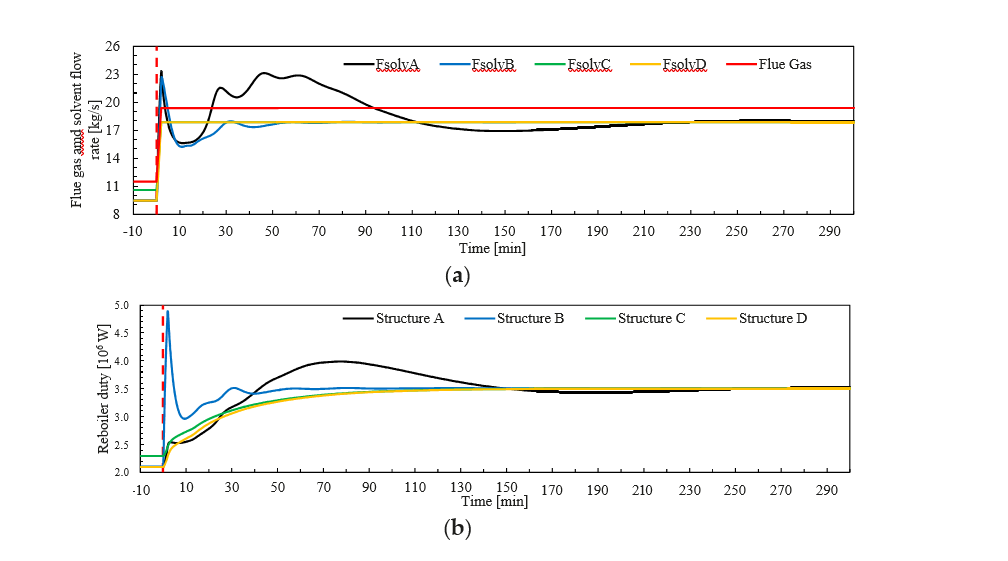

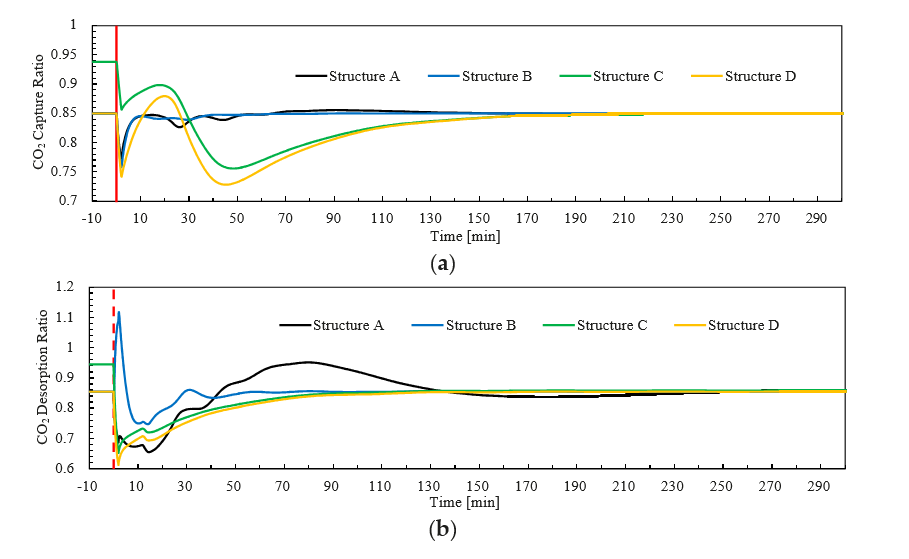

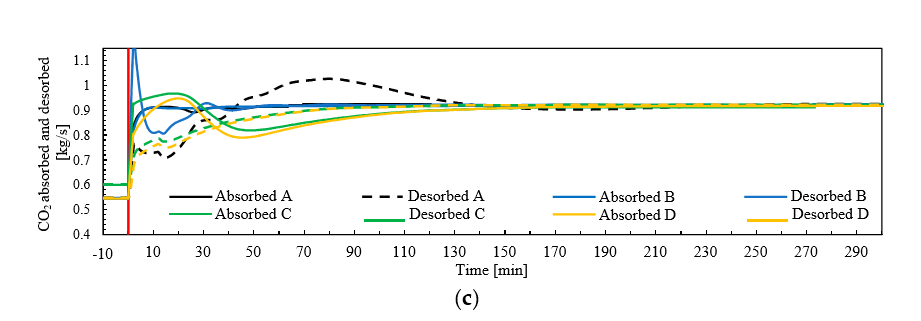

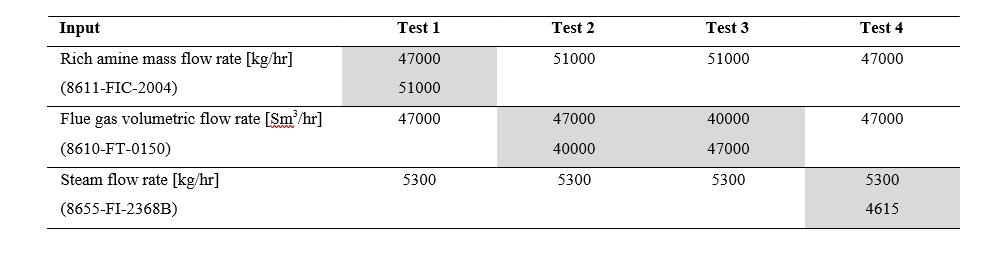

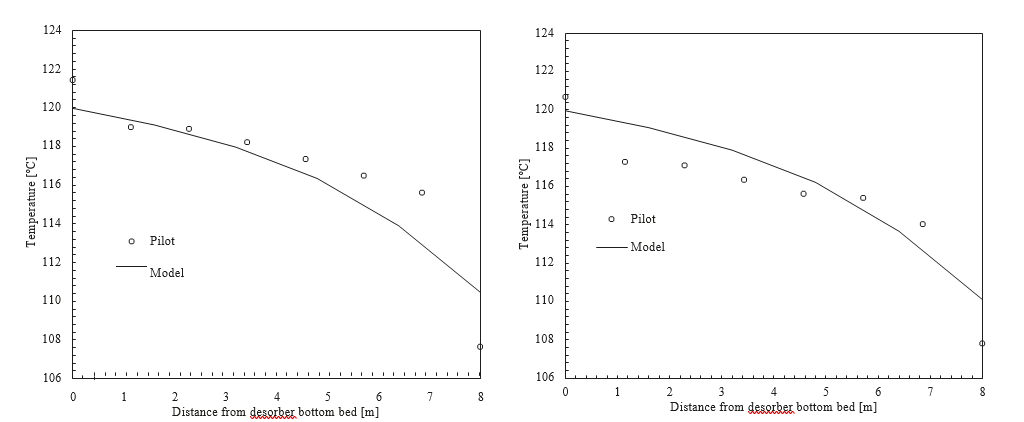

† The difference between CHP and RFCC strippers is in the diameter. CHP stripper ID=1.25 m and RFCC stripper ID=2.2 m. Both strippers are The model validation results are shown in Fig. 2. As it can be seen from the Fig. 2, the model predicts the pilot scale data with good accuracy both for CO2 capture as well as specific reboiler duty (SRD). The outliers or higher deviation in the SRD corresponds to cases where maldistribution and foaming were occurring in the stripper during operation.

After extensive validation with TCM scale pilot data and proven model predictability over wide range of operation window, the TCM Aspen plus model is used for simulating and designing real industrial scale plants.

2.2 Step 2 – Simulation of CO2 capture from NGCC power plant

The present study is to capture CO2 from 555 MWe Natural Gas Combined Cycle (NGCC) power plant. Aqueous 30 wt% MEA solution is used as solvent for capturing CO2. Steady state simulation with aqueous 30 wt% MEA solvent targeting 90% CO2 capture from 555 MWe‡ Natural Gas Combined Cycle (NGCC) power plant. This was based on the case 14 from NETL baseline reference [8] performed with MEA solvent. The flue gas conditions are given in Table 2.

The validated model described in section 2.1 using Aspen plus is used to simulate the design case. The process description for CO2 capture is given in the following paragraphs.

Table 2 555 MWe NGCC plant flue gas conditions for CO2 capture

| Name | Value | Units |

| Flow rate | 113,831 (3,230,636) | kgmol/hr (kg/hr) |

| T | 143 | °C |

| P | 0.1 | MPa, abs |

| Annual operation | 8000 | hours |

| Capture rate | 90 | % |

| Annual CO2 capture | 1,475, 200 | ton/year |

| Composition | Mole fraction | |

| Ar | 0.0089 | |

| CO2 | 0.0404 | |

| H2O | 0.0867 | |

| N2 | 0.7432 | |

| O2 | 0.1209 | |

| NOX | 155 | ton/year |

Flue gas from the NGCC power plant is introduced in direct contact cooler (DCC) to cool it to the required absorber inlet temperature. In the DCC cold water is feed at the top and hot flue gas (143°C) is introduced at the bottom of the DCC column. The flue gas moves counter-current to the cold water over a packed section and gets cooled to the desired temperature and leaves to the absorber via a flue gas blower. The flue gas blower supplies enough pressure to the flue gas to overcome the pressure drop in the absorber. In the DCC, when the incoming flue gas is cooled by contacting with the cold water, water vapor in the flue gas gets condensed. The excess water condensed from flue gas will be bled and the remaining water will be cooled in the DCC water cooler (DCCHEX) and sent back to the DCC top. The flue gas cooling process implementation in Aspen Plus is shown in Fig. 3.

The pre-conditioned flue gas from DCC is fed to the absorber bottom where it meets counter-currently the lean amine fed at the top of absorption section. CO2 is captured by amine via an exothermic reaction forming a carbamate as MEA is primary amine. The lean amine becomes richer and richer as it flows down the absorber column and leaves the absorber bottom via rich amine pump to the stripper via rich/lean cross plate heat exchanger. The flue gas becomes depleted in CO2 on its way upward in the absorber column, due to exothermic reactions in the absorber, the flue gas and amine solvent temperature increases. The NGCC flue gas leaving the absorption section is normally saturated with water and containing volatile components like solvent amine and other amine degradation products. To reduce loss of amine and reduce emission of volatile components such that the plant can be operated within regulated emission permit, the flue gas from the absorption section needs to be cooled and conditioned water washes sections above of the absorber section before sending it to the atmosphere via flue gas stack. In the water wash sections, the flue gas is cooled by counter current flow of cold water, which partially condenses water and some of the volatile components. The condensed stream is fed back either to the bottom of the absorber or can be fed with lean amine feed to the absorber to keep the plant in water balance and reduce the amine loss.

In the stripper the CO2-rich amine solution flows downwards during which CO2 is stripped off from the rich solution by supplying heat in a reboiler with low pressure steam. The CO2-rich gas stream containing CO2, steam, and solvent vapor from the top of the stripper is partially condensed in the overhead condenser and separated from the gas stream in the gas-liquid separator. The condensed liquid is sent to the stripper using reflux pump. The top section of the stripper is a wash/rectification section designed to limit the amount of solvent vapor entering the stripper overhead system.

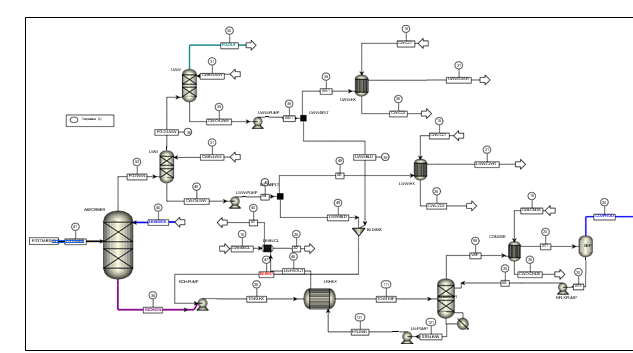

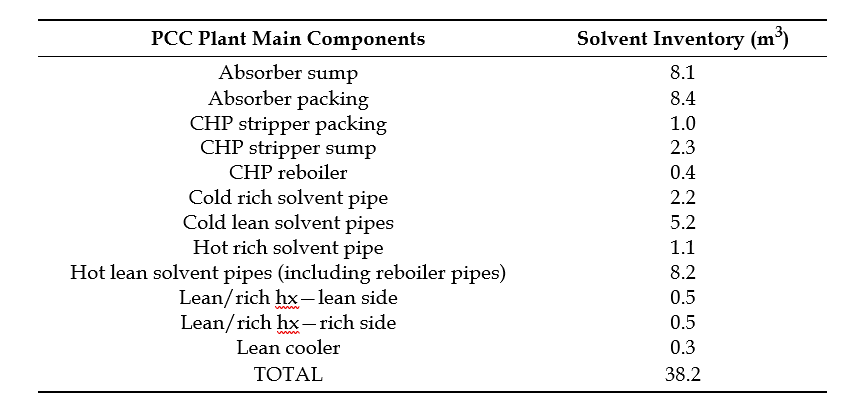

The stripped solvent from the bottom of the stripper, i.e., CO2-lean solution from the bottom of the stripper is cooled-down in the lean/rich cross heat exchanger after heat exchange against the rich solvent; further cooled in the lean amine cooler to achieve the desired temperature for the optimal operation of the absorber. However, solid particles from the feed flue gas could get into the solvent and cause foaming during operation. A split stream of about 5-10% of the circulating solvent is passed through a filtration unit consisting of a mechanical pre-filter, activated carbon bed and post-filter, to remove solid particles and substances that could increase foaming in the solvent. Aspen plus V12 implementation of CO2 capture process is shown in Fig. 4.

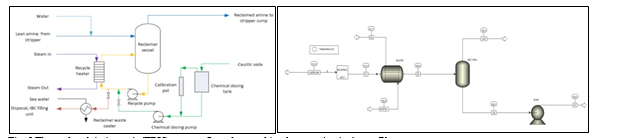

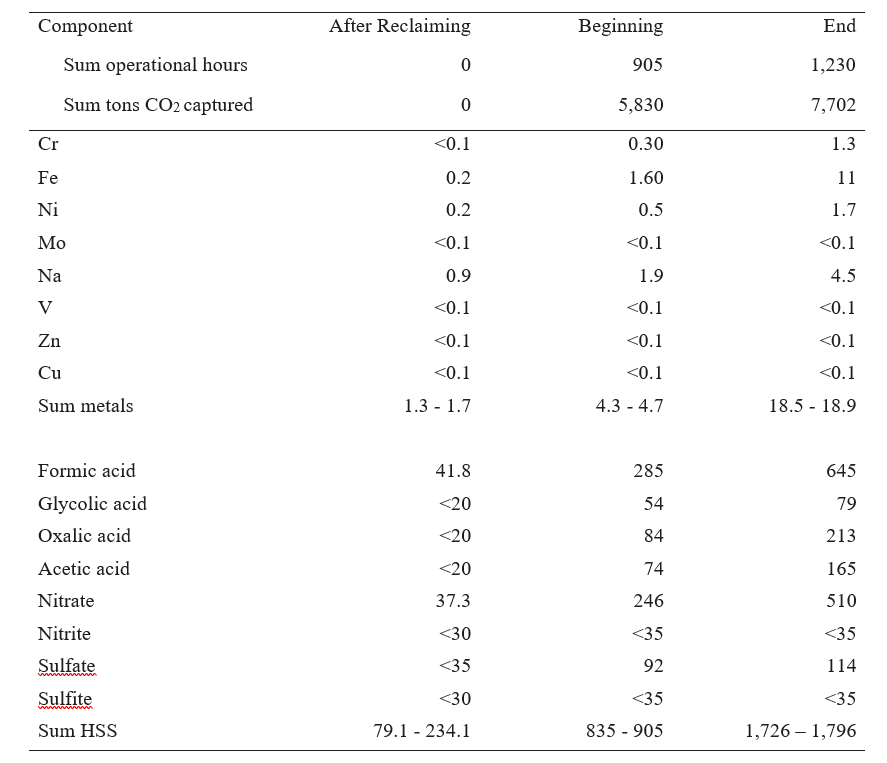

Amine based solvents will degrade over time, the rate of degradation is depending on the solvent molecular stability, flue gas contaminants more specifically NO2, SO2 and O2, operating conditions and plant design (hot inventory). The level and composition of corrosion and solvent degradation products also affect the degradation rate. Capture, HSE and energy performance of the solvent will deteriorate over time unless the solvent is kept in good hygiene to reduce the degradation. One way of keeping the solvent is reclaiming, where a slip stream (normally a slip from hot lean amine stream downstream lean amine pump) is reclaimed in a thermal reclaimer unit (TRU). Reclaiming is performed at higher temperatures than stripper (130-150°C for MEA). Caustic soda (NaOH) is added to the recycle stream to neutralize the acids and liberate MEA. The amount of caustic to inject can be calculated based on the amounts of organic acids (formic, glycolic, oxalic, and acetic), nitrate, nitrite, and sulfate in the solvent. Due to high temperature, water and major portion of the non-degraded amine are evaporated and fed back to the stripper via top of the TRU. The bottom of the TRU contains heavy molecules, some solvent amine and most of the degradation products. These bottoms products are more viscous than solvent amine and are pumped out and disposed as hazardous waste depending on the composition. The reclaiming section schematic and implementation in Aspen Plus is shown in Fig. 5.

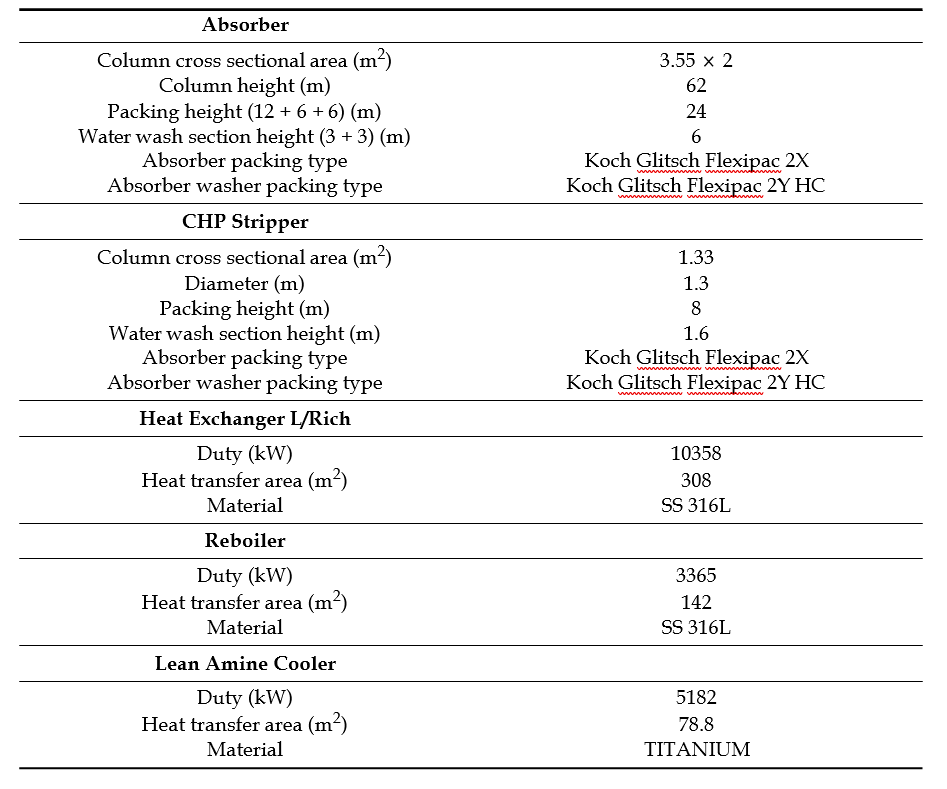

2.3 Step 3 – Equipment sizing

After simulation the CO2 capture unit, the next step is to perform sizing of all essential equipment. This sizing information will be utilized in the next cost estimation step. This section provides some key information and tools

used to perform sizing of different equipment.

- Columns: As Aspen Plus rate-based model is used to perform the simulation in Step 2 above, diameter and packing height is calculated from the Aspen Plus for the selected packing by maintaining good hydrodynamics and meeting the design requirements. In the costing, as the tangent-to-tangent information needs to be provided to get accurate/reliable price for the columns, the spacing required for the internals (e.g., demisters, liquid collectors and distributors, packing supports, sump … etc.) in the columns was calculated based on TCM amine plant columns.

- Plate heat exchangers: The process information from the Aspen Plus simulation is transferred to the Aspen Exchanger Design and Rating (EDR) V12 software and exchanger sizing was performed using the EDR tool to meet the required heat transfer duties and achieve corresponding temperatures for the process/utility streams. The plate types in the plate heat exchangers are selected based on the TCM internal datasheets from the amine plant.

- Reboiler: Kettle type reboilers were designed in the EDR software using the solvent and steam information from the Aspen Plus simulation.

- Separators/vessels: Gas -liquid Separators, reclaimer vessel sizing was performed using Aspen Plus sizing feature.

- Storage tanks: Storage tanks sizes for solvent storage, Caustic storage, reclaimer waste storage was estimated from volume of liquids/solvents from process simulation as well as process operating experience from TCM.

- Cooling towers: Cooling duties and cooling water flowrate were taken from the Aspen Plus simulation performed in step 2. Using this information and cooling towers standards, cooling tower units sizing was considered by discussing with experts working in the industry.

- Filtration unit: Activated carbon filter package sizing was performed assuming that a slip stream of lean amine solvent, i.e., 10% of lean solvent will be sent to filter package.

In addition to the AspenTech softwares, TCM internal tool for reclaimer and TCM internal database have been used in the present study.

2.4 Step 4 – Cost Estimation

This section provides information and methodology followed to estimate the costing using Aspen Capital Cost Estimator (ACCE) V12 software. Step 4 has been performed together with experts from AspenTech. The cost estimations in this work represent the costs that are relative to new plants without considering specific project requirements for design, standards or site integration

AspenTech’s Economic Evaluation solution is based on a core design, estimating, scheduling, and expert systems technology. It automatically develops preliminary design-based economic results – early from minimal scope, and refined designs and economics later in the project. This unique technology provides:

- Key answers quickly

- Dramatic reductions in evaluation time and resources

- The best, most economical process and plant design for funding/bidding decisions and project evaluation.

Aspen economic evaluation systems (including Aspen Capital Cost Estimator and Aspen Process Economic Analyzer) are in daily use. Aspen Capital Cost Estimator uses the equipment models contained in the Evaluation Engine – a knowledge base of design, cost, and scheduling data, methods, and models – to generate preliminary equipment designs and simulate vendor-costing procedures to develop detailed Engineering-Procurement- Construction (EPC) estimates. Volumetric models generate a costed, quantity takeoff for the bulk materials without using factors or user input. The volumetric models also produce the quantities of pipe, valves, concrete, steel, and instruments identified by the associated equipment or area. Components of each line of pipe and instrument loop are quantified and costed, enabling the user to view and adjust construction tasks. The Aspen Capital Cost Estimator Work Item Models produce the required man-hours by craft and task needed to install Aspen Capital Cost Estimator- generated bulks, as well as the equipment Aspen Capital Cost Estimator designed, by simulating detailed design construction tasks. Finally, the Engineering Models in Aspen Capital Cost Estimator produce man-hours by discipline and engineering work product.

Cost indices in the economic evaluation suite and Aspen Capital Cost Estimator include engineering disciplines, wage rates, material costs, shop and field labor rates, construction equipment rental rates, etc. These indices do not derive from public sources, and they may not accurately reflect how they affect a specific project. To evaluate this, the user should run benchmark projects and develop own adjustments.

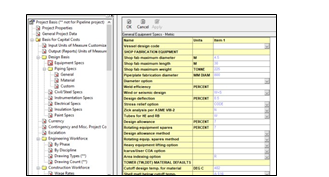

2.4.1 Aspen Capital Cost Estimator Project General Workflow

- Create project scenario and define properties like country base, units of measure, and currency.

- Define design basis (general mechanical design rules), wage rates and productivities, code of account definition and allocation, material and man-hour indexing, equipment rental, and project execution schedule settings.

- Define the Power Distribution system (if desired).

- Define the Process Control system (if desired) and link to areas and substations.

- Add contractors and redefine responsibilities (if desired) and link to areas and substations.

- Run an item evaluation to produce direct costs for an individual component or run a project evaluation to produce design and cost results needed to prepare project reports.

- View and/or print reports.

2.4.2 Generating the economic evaluation for this project

The economic evaluation project with the equipment list can be generated in simulation either within the simulation itself or by importing the simulation file into ASPEN CAPITAL COST ESTIMATOR. The economic evaluation can be started from within the simulation, by setting the economics active in the economic evaluation tab, as shown in Fig. 6.

The simulation will generate a preliminary estimate based on default values; however, these values should be reviewed by the user. The first thing to review will be the mapping process.

Simulations and estimates differ in the sense that a theoretical unit operation is not the same as pieces of equipment set on a plant. For example, a column unit operation may converge for heat and mass balance, but when estimating it, an actual distillation process needs the column vessel, the reboilers, the condensers and accumulators as well as the pumps to circulate the condensate. Furthermore, mapping is important because while a heat exchanger may be represented by a simple unit operation, for estimation it will be very important to define if the type is an air cooler, shell and tube exchanger or others. Lastly, the mapping exercise will also have an impact on the bulks cost calculated by the economic evaluation engine for example a separator in a simulation may represent a process vessel or a storage tank and these will have greatly different impact in the piping and instrumentation associated to each of them as shown in Fig.7.

As the Fig.7 illustrates below, a horizontal process vessel needs more piping and instrumentation items than a general storage tank would. This has an impact in the final estimated project cost.

Once the mapping exercise is done the, the economic evaluation technology integrated in the simulation will perform a sizing of the equipment list generated in the previous list. This sizing considers the mass and energy balances calculated in the simulation and sizes the equipment following standards defined in the design bases under “cost options”. Design Basis defines the general mechanical design rules for the entire project. AspenTech’s Economic Evaluation uses built in, industry-standard design procedures for the preparation of mechanical designs. The standards used include ASME (American Standards), BS5500 (British Standards), JIS (Japanese Standards), DIN (German Standards), or EN 13445 (European Standards).

Finally given the equipment list and design generated in the economic evaluation, a preliminary cost analysis will be generated for the equipment listed in the simulation which includes the material cost as well as the installed cost of the equipment list, it will also include a preliminary operational cost given the utilities defined in the simulation (ACCE has default utilities defined in case a user does not define them manually) and generates an “IZP” file that is readable by Aspen Capital Cost Estimator, AspenTech’s detailed estimating tool.

It is important to mention that an estimate generated from the simulation and the cost results displayed in the simulation are just a preliminary cost. For an asset’s total install cost (TIC) to be completely estimated, it still needs definitions of structures such as Pipe Racks, the Piping that will interconnect multiple areas, Control Centers, Power Distributions, any and all skids for the dosage packages etc. User input is required for labor wage rates, productivities, escalation indexes, utilities cost definitions, licensor and other indirect costs, contingency costs, etc. For this, previously generated IZP file is imported into Aspen Capital Cost Estimator and add more details to the existing estimate to create a higher quality estimate that can be backed up with better data.

Open the IZP file in Aspen Capital Cost Estimator and review the Project Basis. So far, default values have been used, however have more control within the Aspen Capital Cost Estimator User Interface to adjust and modify the cost and design basis to meet the needs.

In the Equipment Specs form under Design Basis, design information specific to the project needs to be entered, such as:

- Design allowances

- Rental equipment option for lifting

- Shop fabrication specifications

- Design cut off temperature

Notice default values are light blue colored while user entered values will be black as shown in Fig. 8.

Continuing under Project basis view, user will find General Piping Specs form. Enter here information such as Pipe fabrication preferences, tracing tube material, X-ray analysis percentage, insulation jacket material, etc.

As moving on to the next form Civil/Steel Specs will be displayed. This form will let the user enter information about plant site such as soil type, loading density, wind velocity, pile types and sizes. All this data is used to calculate the amount of civil work needed to setup the equipment, for example how much foundation the columns need as well as structural steel, all key parts of the direct cost estimated.

Continuing, next to the Instrumentation Specs Form. This form allows the user to enter information about the instrumentation configuration needed in the project, such as P&ID design, Instrumentation type and system, Junction Box distances and cable size option. Entering this information will affect the quantity of material needed for instrumentation, the type of material used and will directly affect the Instrumentation code of account direct cost. The most important modification done for this project will be the type of instrumentation, as the default Pipe and Instrumentation design (P&IDs) is changed from Standard Instrumentation to Fully Instrumented (FULL). One important point to consider here using the domain knowledge, even the fully instrumented option still doesn’t have all the required instrumentation for few equipment, such as absorber column which contains both absorption and water wash sections in the same column. User needs to add additional instrumentation required manually. This option is available in ACCE.

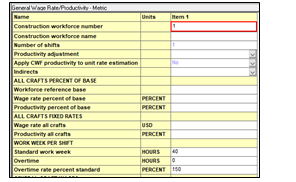

Wage Rates form is available under the Construction Workforce folder. This form shown in Fig. 9 allows to enter data for wage rates, productivities, shifts per workday, overtime wage rates. This information is used to calculate the total labor hours needed to install all equipment and bulks, reflected in the direct costs.

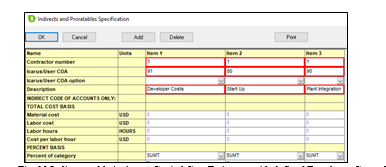

To add Indirect cost such as Developer Cost, Plant Integration and Start Up as a percentage of the EPC cost, user can add them to the “Indirect Prorate-able” table, in this table users are able to define costs as percentage basis of the EPC cost and can also organize said costs as direct costs by defining its “code of account” a code that allows for reporting purposes where should the cost be displayed. An example of how this table looks can be seen in Fig. 10.

Moving into Project basis, there are other aspects of an EPC estimate that have been not considered so far. The Aspen Plus simulation link with Economic Evaluation gave us the major pieces of equipment present in the project, however items such as pipe racks, interconnecting piping with the outside battery limits, motor control centers, and even services such as dosage packages and cooling towers are not present in a normal simulation but are important to be considered when evaluating the capital cost of a project. Items can be added manually from the Aspen Capital Cost Estimator library of components as shown in Fig. 11.

For items like the dosage packages, user can add them as vessels and pumps that are mounted on skids. ACCE allows us to add these skids and reuse them in future projects as new library items.

Once user has completed the scope of the direct costs entered in Project View and the Indirect Costs entered in Project Basis, user can evaluate the estimates to generate reports to give the CAPEX of the project.

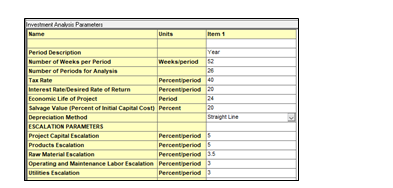

To analyze the OPEX of the project is important to correctly define the Investment Parameters form for the asset. The Economic Evaluation soluition provides a standard form with data, but defining correctly the Economic Life of the Project, the number of years and how many weeks per year, will be important for this analysis. User should also define how many hours will the asset will be operating per year as shown in Fig. 12.

It is important to set-up operating unit costs, that allows to define operator and supervision costs that will be needed year over year to operate the asset/plant. Raw material cost is also necessary for this analysis, in this case, defining the cos of the MEA will be key. Lastly defining the utilities costs for steam, cooling water, electricity and intrumentation air will allow the software incorporate these costs into the Investment Analysis and provide a breakdown of the costs year over year of the asset.

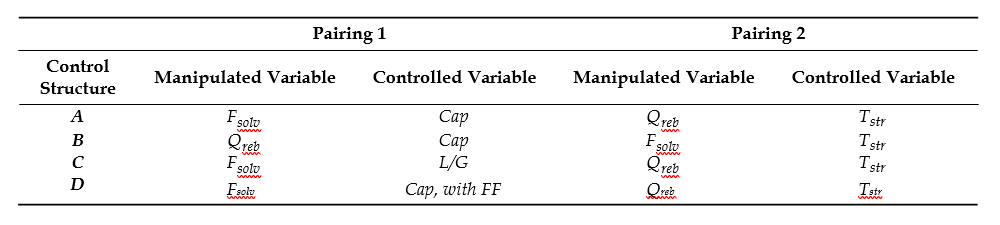

3. Results and Discussion

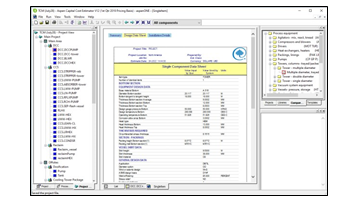

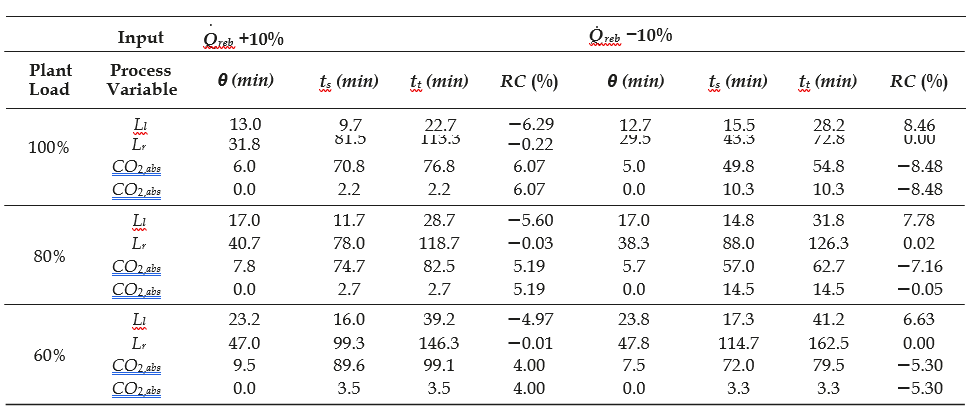

After finishing the step 4, the user needs to evaluate the project in ACCE to get costing report for the project. The user has the possibility to select interactive excel based report. ACCE will generate extensive report with 99 different types of summaries related to the project. In this section (step 5), the main focus will be on the results generated/estimated from the economic analysis to get insights like capital and operating costs and cost of CO2 capture per ton. The cost basis used for economic analysis in ACCE V12 is 2019 Q1. This is considered as base year for TCM costing estimations.

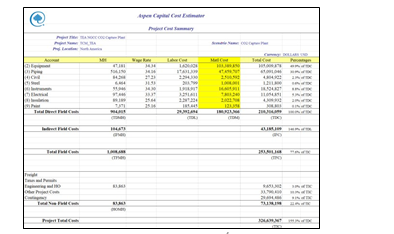

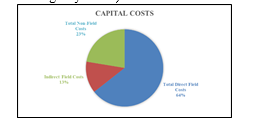

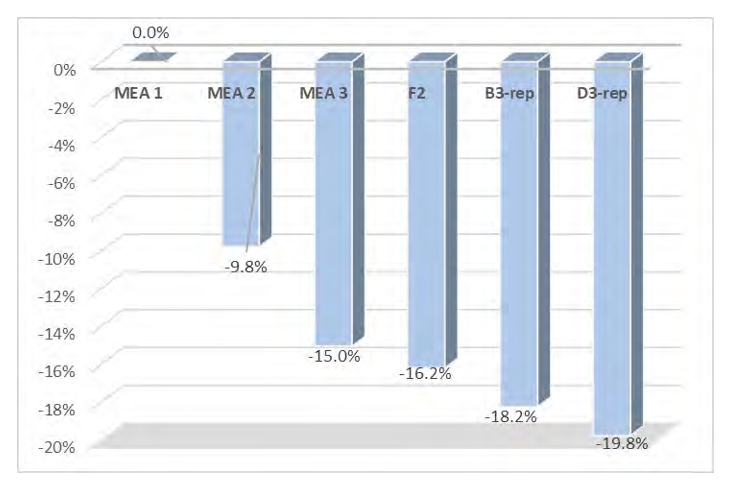

The Capital cost summary with various details, estimated by ACCE is shown in Fig. 13 below. The total capital cost (referred to as Project Total Costs in ACCE and Fig. 13) for capturing 90% CO2 from 555 MWe Natural Gas Combined Cycle (NGCC) power plant using aq. 30 wt% MEA solvent, estimated by ACCE is around 326.6 MUSD. The equipment cost (~105 MUSD) corresponds to 32% of Project Total Costs.

The direct and indirect field costs summary is shown in Fig. 14. Direct field costs contribute to 64% of total capital costs. Direct field costs include equipment, piping and instrumentation, civil and steel structures, insulation, and paint required. Indirect field costs include scaffolding, consumables like small tools and consumable materials, construction rental equipment costs, startup and commission, field supervision …etc. Non-field costs include engineering costs (basic, detailed engineering and materials procurement, contract fees, general, and administrative overheads, and contingency …etc.)

§ According to the current market data, the cost for plate heat exchangers is overestimated in ACCE V12. This can be modified by recalibrating the plate heat exchangers costs in ACCE using vendor quotes. This calibration was performed by using costing data from CO2 capture projects, calculating the over-estimation factor and indexing the data accordingly, matching market data.

The materials cost summary of CO2 capture plant is shown in Fig. 15. Columns material costs account for 63% of total equipment material costs and absorber accounts for 45% of total equipment material costs.

In order to understand and verify the accuracy of the cost estimates from the present work, a comparison has been made with NETL baseline study cost estimates [8]. In the NETL baseline study, flue gas pre-conditioning is not considered. Therefore, a comparison is made after excluding the flue gas pre-conditioning section (all associated equipment) which represent a reduction of 18% of the total equipment costs. The CAPEX for equipment (total field costs) estimated by ACCE is around 172.8 MUSD and prorating the NETL baseline costs using the chemical engineering plant cost index (CEPCI) estimated to be around 162.1 MUSD. This translates into 6.5% increase in costs, which is an acceptable deviation, as shown in Table 3.

Table 3 TCM Aspen and NETL baseline cost estimates comparison

| Name | TCM | NETL |

| Cost base | 2019 Q1 | 2007 June |

| Capital costs excluding flue-gas pre-conditioning (direct), MUSD | 172.8 | 140.0 |

| Prorated costs to TCM base year, MUSD | – | 162.1 |

| Difference (%) | – | 6.5 |

Operating costs for the CO2 capture plant will include costs for manpower, utilities (cooling water, steam, process water), power and solvent makeup, other chemicals and waste handling costs. It is assumed that on annual basis, cooling water make-up will be 10% to compensate for bleed. Solvent costs will require an estimate of solvent lost due to degradation, evaporation losses as well as solvent lost in the waste during reclaiming. TCM internal tool for reclaiming has been used to estimate the annual total solvent makeup required. Solvent and reclaimer waste handling costs are taken from TCM internal quotes.

The total annual operating costs are estimated to be 47 MUSD. With MEA cost of 2000 USD/ton, the solvent makeup costs account for 15% of the total operating costs and these costs share increases to 20% with 3000 USD/ton MEA price. Solvent degradation is very crucial when it comes to optimizing the CO2 capture projects operating costs.

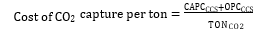

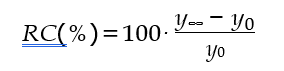

Cost of CO2 capture per ton:

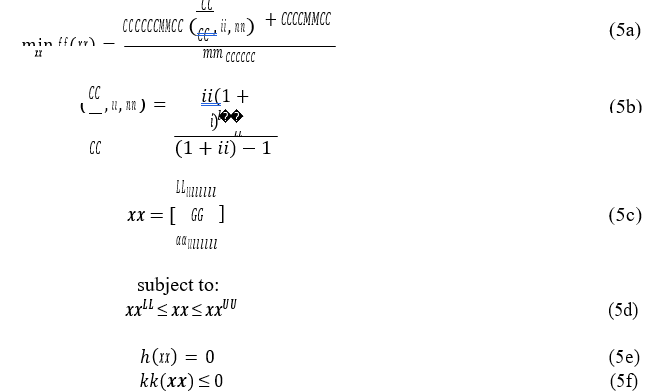

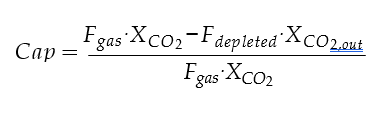

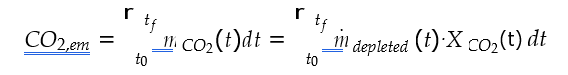

Cost of CO2 capture per ton is calculated using the following equation (9) [12].

Where CAPCCCS represents annualized capital investment costs and OPCCCS represents annual operational costs of CO2 capture plant and TONCO2 represents tons of CO2 removed in a year.

With 25 years of plant life and 5% discount rate, the cost of CO2 capture per ton is calculated to be 47 USD and the cost increases to 50 USD with 3000 USD/ton MEA solvent price, i.e., 6.4 % increase.

4. Conclusions

An extensive study has been conducted by Technology Centre Mongstad together with AspenTech to develop CO2 capture process cost baseline for 555 MWe NGCC power plant using non-proprietary 30 wt% MEA solution as solvent to guide project developers as well as new technology developers to assess the project feasibility as well as merits of new technologies.

This study explains in detail all the essential steps involved in developing a cost baseline starting from the model development, validation with pilot scale operational data, simulation of process at the desired scale, detailed equipment design, project costs estimation and finally analysis of the costs to estimate cost of CO2 capture. Multiple AspenTech software tools (Aspen Plus, Aspen EDR, ACCE) as well as TCM internal calculation tools together with TCM practical operational knowledge is used to come up with reliable costing.

From the current study, it can be seen that using AspenTech products together with domain expertise, amine based post-combustion carbon capture projects costs can be estimated and these estimates can provide reliable budgetary estimation for CO2 capture projects.

For FEED studies, the accuracy of the total project estimation is likely not sufficient since FEED studies are often relative to specific sites. But the estimation of alternatives (process, utilities) may be useful with AspenTech tools during FEED studies.

For other studies, AspenTech tools are useful for:

- Feasibility studies

- Screening of project alternatives

- Conceptual studies

- Preliminary cost estimations

Acknowledgements

The authors gratefully acknowledge the staff of TCM DA, Gassnova, Equinor, Shell and TotalEnergies for their contribution and work at the TCM DA facility. The authors also gratefully acknowledge Gassnova, Equinor, Shell, and TotalEnergies as the owners of TCM DA for their financial support and contributions. The authors also thank AspenTech for providing working sessions for the present study

References

- D. Thimsen, A. Maxson, V. Smith, T. Cents, O. Falk-Pedersen, O. Gorset, E.S. Hamborg, Results from MEA testing at the CO2 Technology Centre Mongstad. Part I: Post-Combustion CO2 capture testing methodology, Energy Procedia. 63 (2014) 5938–5958. https://doi.org/10.1016/j.egypro.2014.11.630.

- E.S. Hamborg, V. Smith, T. Cents, N. Brigman, O.F.- Pedersen, T. De Cazenove, M. Chhaganlal, J.K. Feste, Ø. Ullestad, H. Ulvatn, O. Gorset, I. Askestad, L.K. Gram, B.F. Fostås, M.I. Shah, A. Maxson, D. Thimsen, Results from MEA testing at the CO2 Technology Centre Mongstad. Part II: Verification of baseline results, Energy Procedia. 63 (2014) 5994–6011. https://doi.org/10.1016/j.egypro.2014.11.634.

- L. Faramarzi, D. Thimsen, S. Hume, A. Maxon, G. Watson, S. Pedersen, E. Gjernes, B.F. Fostås, G. Lombardo, T. Cents, A.K. Morken,M.I. Shah, T. de Cazenove, E.S. Hamborg, Results from MEA Testing at the CO2 Technology Centre Mongstad: Verification of Baseline Results in 2015, Energy Procedia. 114 (2017) 1128–1145. https://doi.org/10.1016/j.egypro.2017.03.1271.

- C. Benquet, A.B.N. Knarvik, E. Gjernes, O.A. Hvidsten, E. Romslo Kleppe, S. Akhter, First Process Results and Operational Experience with CESAR1 Solvent at TCM with High Capture Rates (ALIGN-CCUS Project), SSRN Journal. (2021). https://doi.org/10.2139/ssrn.3814712.

- S.A. Hume, M.I. Shah, G. Lombardo, T. de Cazenove, A. Maxson, C. Benquet, Results from MEA testing at the CO2 Technology Centre Mongstad. Verification of Residual Fluid Catalytic Cracker (RFCC) baseline results, SSRN Electronic Journal. (2021) 12.

- B. Languille, A. Drageset, T. Mikoviny, E. Zardin, C. Benquet, Ø. Ullestad, M. Aronson, E.R. Kleppe, A. Wisthaler, Atmospheric Emissions of Amino-Methyl-Propanol, Piperazine and Their Degradation Products During the 2019-20 ALIGN-CCUS Campaign at the Technology Centre Mongstad, SSRN Journal. (2021). https://doi.org/10.2139/ssrn.3812139.

- S.A. Hume, B. McMaster, A. Drageset, M.I. Shah, E.R. Kleppe, Results from CESAR1 testing at the CO2 Technology Centre Mongstad. Verification of Residual Fluid Catalytic Cracker (RFCC) baseline results, in: Lyon, France, 2022.

- J. Haslback, N. Kuehn, E. Lewis, L.L. Pinkerton, J. Simpson, M.J. Turner, E. Varghese, M. Woods, Cost and Performance Baseline for Fossil Energy Plants, Volume 1: Bituminous Coal and Natural Gas to Electricity, Revision 2a, National Energy Technology Laboratory (NETL), Pittsburgh, PA, Morgantown, WV, and Albany, OR (United States), 2013. https://doi.org/10.2172/1513268.

- K.R. Putta, D.D.D. Pinto, H.F. Svendsen, H.K. Knuutila, CO2 absorption into loaded aqueous MEA solutions: Kinetics assessment using penetration theory, International Journal of Greenhouse Gas Control. 53 (2016) 338–353.

- AspenTech, Rate-Based Model of the CO2 Capture Process by MEA using Aspen Plus, 2018.

- K.R. Putta, H.F. Svendsen, H.K. Knuutila, Kinetics of CO2 Absorption in to Aqueous MEA Solutions Near Equilibrium, Energy Procedia. 114 (2017) 1576–1583.

- S. Roussanaly, N. Berghout, T. Fout, M. Garcia, S. Gardarsdottir, S.M. Nazir, A. Ramirez, E.S. Rubin, Towards improved cost evaluation of Carbon Capture and Storage from industry, International Journal of Greenhouse Gas Control. 106 (2021) 103263. https://doi.org/10.1016/j.ijggc.2021.103263.

Development of process model of CESAR1 solvent system and validation with large pilot data (2022)

Joshua C. Morgana,b,*, Matthew Campbellc, Koteswara Rao Puttac, Muhammad Ismail Shahc, Michael Matuszewskia,b, Benjamin Omella

a National Energy Technology Laboratory (NETL), 626 Cochrans Mill Road, Pittsburgh PA, 15236

b NETL Support Contractor, 626 Cochrans Mill Road, Pittsburgh PA, 15236

c CO2 Technology Centre Mongstad, Mongstad 71, 5954 Mongstad, Norway

*Corresponding author. Tel.: +1-412-386-5357, E-mail address: Joshua.Morgan@netl.doe.gov

Abstract

The United States (U.S.) Department of Energy (DOE)-sponsored Carbon Capture Simulation for Industry Impact (CCSI2) is collaborating with Norway’s Technology Centre Mongstad (TCM) on the development and validation of a process model of the CESAR1 solvent system for post-combustion carbon capture applications. The CESAR1 solvent, developed through the CO2 Enhanced Separation and Recovery (CESAR) project, is an aqueous blend of 2-amino-2-methyl-1-propanol (AMP) and piperazine (PZ) with concentrations of approximately 3 M and 1.5 M, respectively. The process model, developed in the Aspen Plus® software platform, uses thermodynamic and kinetic models from the AMP-H2O-CO2 and PZ-H2O-CO2 system models distributed by Aspen Tech. Enhancements in this work include calibrating the interaction parameters for the AMP-PZ pair with thermodynamic data from the open literature for the AMP-PZ-H2O-CO2 system and updating the reaction kinetics parameters to ensure thermodynamic consistency with the chemical equilibria. The process model is validated with a set of seven steady-state test runs, collected over a wide range of operating conditions at the pilot plant at TCM (12 MWe scale) with natural gas-based combined cycle turbine flue gas (~ 3.5 vol% CO2). The integrated process model developed for the TCM pilot plant includes rate-based models for the CO2 absorption and solvent regeneration processes and predicts key output variables (e.g., CO2 capture percentage, specific reboiler duty) within ± 5% for the validation data set. This paper presents model development and validation work for an initial version of the CESAR1 process model along with discussion of future updates to be made to the model prior to its open-source release.

1. Introduction

The United States (U.S.) Department of Energy (DOE)-sponsored Carbon Capture Simulation for Industry Impact (CCSI2) is a collaboration among national laboratories, industry organizations, and academic institutions focused on application of the open-source toolset developed through its predecessor program, Carbon Capture Simulation Initiative (CCSI) [1]. The CCSI Toolset (https://github.com/CCSI-Toolset) includes a suite of computational tools and models for accelerating the development, deployment, and scale-up of CO2 capture technologies. This toolset includes a process model, implemented in Aspen Plus®, of a monoethanolamine (MEA)-based carbon capture process, which was validated with steady-state data from the National Carbon Capture Center (NCCC) [2–3] and Technology Centre Mongstad (TCM) [4], at scales of 0.5 and 12 MWe, respectively. TCM, owned jointly by Gassnova, Equinor, Shell, and TotalEnergies, is the world’s largest facility for evaluation of novel process technologies in the carbon capture and storage (CCS) field. The TCM staff also provides expertise in process modeling and analysis in addition to 10 years of experience in CCS process operation. In a recent work by Putta et al. [5], TCM has collaborated with Aspen Tech on a rigorous economic analysis of a natural gas combined cycle (NGCC) power plant integrated with an aqueous MEA CO2 capture system achieving 90% capture. This work uses a model of the MEA system that has been validated with process data from TCM for operation with various flue gas sources: natural gas-based (~ 4 vol% CO2), steam- methane reform-based (~ 8-10 vol% CO2), and coal-based (~ 12-14 vol% CO2). In contrast, the previous MEA model developed by the CCSI/CCSI2 team [2–4] has been validated with NCCC data for 7-12 vol% CO2 flue gas and TCM data for 8-10 vol% CO2 flue gas and has yet to be re-evaluated for operation with natural gas-based flue gas.

This paper is based on a collaboration between CCSI2 and TCM focused on the development and validation of a process model of a second-generation amine solvent (CESAR1) for point source carbon capture applications. The CESAR1 solvent, developed through the CO2 Enhanced Separation and Recovery (CESAR) project, is an aqueous blend of 2-amino-2-methyl-1-propanol (AMP) and piperazine (PZ) with concentrations of approximately 3 M (5 m) and 1.5 M (2.5 m), respectively. This corresponds to an aqueous solution of approximately 27 wt% AMP and 13 wt% PZ. This solvent blend has been identified as an improvement over MEA, long considered the nonproprietary standard for solvent-based carbon capture, due to the combination of high reactivity associated with PZ and the lower heat of absorption of AMP, which leads to a reduction in solvent regeneration energy requirement [6–7] as well as stability of the solvent (lower solvent degradation rates).

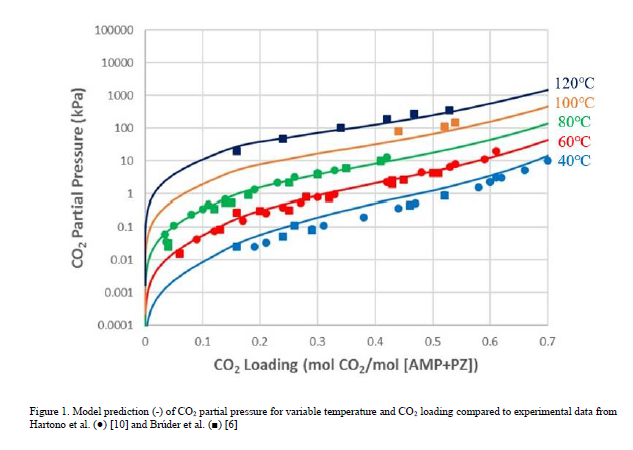

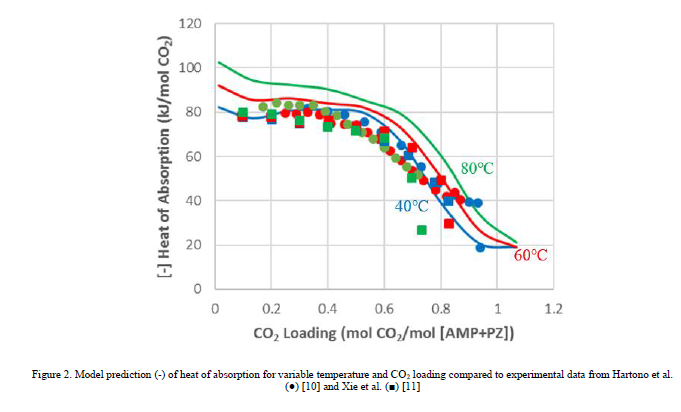

In this work, the CESAR1 process model was developed by combining existing thermodynamic models distributed with Aspen Tech software of the CO2-loaded aqueous PZ [8] and AMP [9] systems and regressing the interaction parameters for the PZ–AMP pair to fit CO2 partial pressure [6, 10] data for the temperature range of 40–120℃ and heat of absorption data for 40–80℃ [10–11]. A simulation of the pilot plant at TCM was developed in Aspen Plus, with absorber and stripper columns modeled as rate-based columns. In the absorber model, reactions are specified on activity basis with forward and reverse kinetic parameters fit to ensure consistency with the chemical equilibria calculated from the solution thermodynamic model. The process model is validated with seven steady-state data sets from the TCM pilot plant, and the overall model validation set includes variation in solvent (35000–65000 kg/hr) and flue gas flowrates (60000–70000 kg/hr), solvent CO2 loading (0.049–0.176 mol CO2/mol alkalinity), and absorber packing height (12–24 meter). The process model accurately predicts, generally within ± 5%, the key output variables of interest for the process, including percentage of CO2 capture from absorption and reboiler duty for solvent regeneration. Finally, future work on the CESAR1 model, which will be released to the open-source CCSI Toolset in the near future, is discussed. This includes sub-model level uncertainty quantification (UQ) and the extension of the thermodynamic model to operating conditions for the water wash column to allow for accurate characterization of solvent emissions.

2. Model Development

2.1 Thermodynamic Model

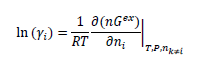

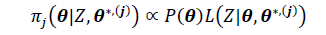

The thermodynamic models for the CO2-loaded aqueous PZ and AMP systems were adapted from the documentation distributed with Aspen Tech software [8–9]. In these models, the liquid and vapor phase fugacity values are calculated from the electrolyte non-random two liquid (e-NRTL) model [12] and the Redlich-Kwong equation of state, respectively. Thermodynamic data of relevance to the combined AMP-PZ-H2O-CO2 system were identified from the literature. Hartono et al. [10] includes CO2 partial pressure data and heat of absorption for solutions at 40–80℃. Brúder et al. [6] includes a CO2 partial pressure data set that is generally consistent with that of Hartono et al. [10], but also includes data for 100–120℃, the temperature range of interest for stripping CO2 from solvent. A data set for heat of absorption for solutions at 40–80℃ from Xie et al. [11] was also identified. The parameters of interest for characterizing the AMP-PZ interaction in the activity coefficient model are embedded in the local interactions term in the e-NRTL model for excess Gibbs energy, which is related to the activity coefficient as follows:

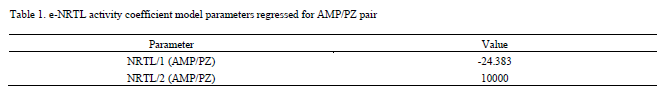

A summary of the e-NRTL activity coefficient model and the details of the parameters used for fitting solvent- based CO2 capture systems is found in our previous work on thermodynamic modeling of the aqueous MEA system [13]. The regressed parameter values for the molecule-molecule interaction for the AMP/PZ pair are given in Table 1. These values were estimated through use of a maximum likelihood objective function implemented in the Aspen Plus data regression system.

When developing this model, it was assumed that the binary pair parameters for the AMP-PZ interaction are symmetric, in that the values for NRTL/1 and NRTL/2 are equal for (AMP/PZ) and (PZ/AMP) pairs. It was found that simultaneous regression of the parameters for (PZ/AMP) in addition to those for (AMP/PZ) did not result in a statistically significant improvement in the model. Furthermore, the model fit did not significantly improve when regressing electrolyte pair parameters for the AMP-PZ interaction. The fit of the model to CO2 partial pressure and heat of absorption data is shown in Figures 1–2, respectively.

As shown in Figures 1-2, the model generally gives good prediction of the CO2 partial pressure isotherms and captures the trend of heat of absorption with respect to the lean loading. For the CO2 partial pressure, the R2 values for the model fits are 0.922 for data from Brúder et al. [6] and 0.876 for data from Hartono et al. [10]. There is some discrepancy among the two data sources used for heat of absorption [10–11] and the effect of temperature on heat of absorption is unclear. The model predicts that the magnitude of heat of absorption increases with temperature, consistent with the observation for the aqueous MEA system [13]. As a result of this discrepancy, the R2 values for the model fit are lower for the heat of absorption than for the CO2 partial pressure – 0.835 for the data from Hartono et al. [10] and 0.815 for the data from Xie et al. [11]. As the model fit to both heat of absorption and CO2 partial pressure data is generally good at 40°C and 60°C, it is expected that the model will predict with reasonable accuracy absorber operation, in terms of both CO2 capture and temperature bulge due to the exothermic reaction between CO2 and amine. Since no heat of absorption data are available for temperatures above 80°C, the heat of absorption is extrapolated in the modeling of the stripper column, and further analysis would be required to determine the effect this has on model accuracy. Further improvements to the thermodynamic model would likely require uncertainty quantification, for which discussion is forthcoming, or reevaluation of the accuracy of the thermodynamic models of the AMP-H2O-CO2 and PZ-H2O-CO2 subsystems.

2.2 Chemical Equilibrium and Kinetic Models

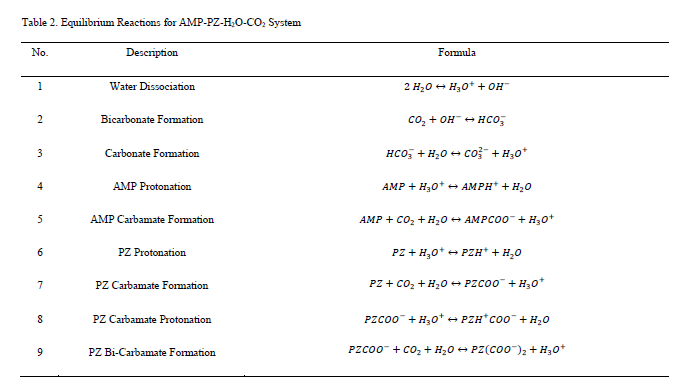

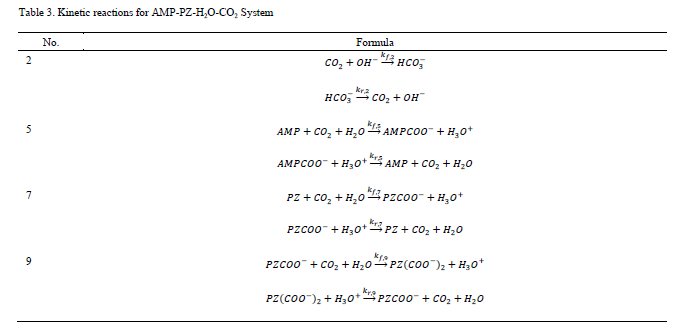

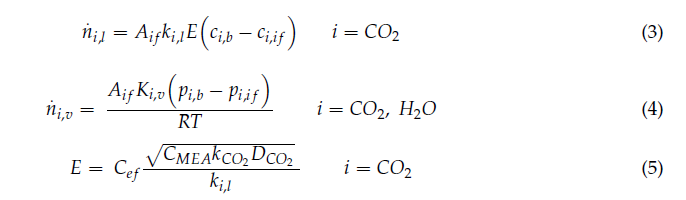

In this work, the solution chemistry for the AMP-PZ-H2O-CO2 system is represented by the equilibrium reactions shown in Table 2 [8-9].

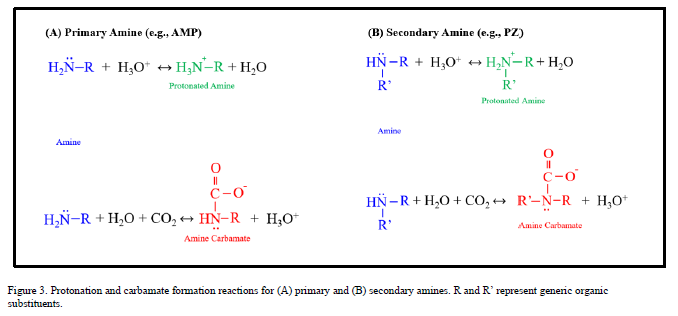

The aggregate reaction set includes amine-independent reactions (No. 1–3) that describe the interactions of CO2 and H2O in addition to reactions specific to each amine sub-system. The amine-specific reactions are represented schematically in Figure 3.

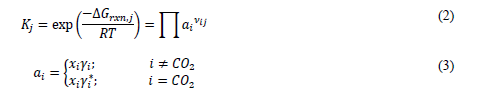

The chemistry of AMP (No. 4–5), a sterically hindered primary amine, is typical for a CO2-loaded aqueous amine system. The amine molecule is in equilibrium with its protonated form through a proton exchange reaction. The amine also forms a carbamate through displacement of a proton by CO2. The chemistry of PZ (No. 6-9), a cyclic compound with two secondary amine groups is more complex in that the additional amine group on the PZ carbamate ion [PZCOO-] can react with hydronium to form a zwitterion [PZH+COO-] or with CO2 to form a bi-carbamate ion [PZ(COO-)2]. For each equilibrium reaction (j), the chemical equilibrium constant is defined as:

Note that CO2 is defined as a Henry component in the model. Thus, the activity is defined in terms of the asymmetric activity coefficient, whereas the symmetric activity coefficient is used for all other species. As in the process models distributed with Aspen Plus [8–9], only the reactions involving CO2 are represented as kinetic reactions in the absorber model. These are summarized in Table 3.

For each reaction (j) for which kinetics are defined, the rate expressions for both forward and reverse reactions are in elementary form and use activity as the concentration basis. The forward reaction rate constants are represented as:

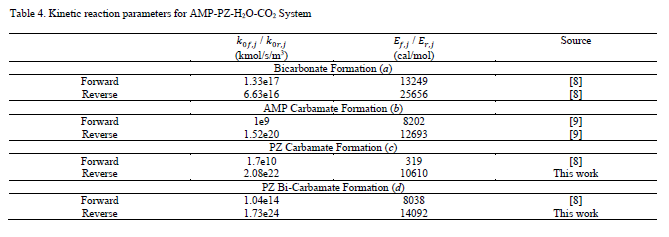

The reverse reaction rate constants are defined analogously. Kinetic parameters for all reactions are given in Table 4.

In determining the kinetic parameters for the individual reactions, the rate constants of the forward and reverse reactions should be related to the chemical equilibrium by:

As the kinetic parameter values provided for the bicarbonate formation and AMP carbamate formation reaction in the Aspen Tech models [8–9] are consistent with the chemical equilibria as shown in Eq. 5, these parameter values are also used in this work. This consistency was not observed for the PZ carbamate and bi-carbamate formation reactions, and the reverse rate parameters (𝑘0𝑟,𝑗 and 𝐸𝑟,𝑗) were adjusted to ensure that Eq. 5 is also satisfied for each reaction. This model update was found to be essential not only for ensuring consistency between thermodynamic and kinetic sub-models, but also for obtaining adequate prediction of absorber performance.

2.3 Pilot Plant Model

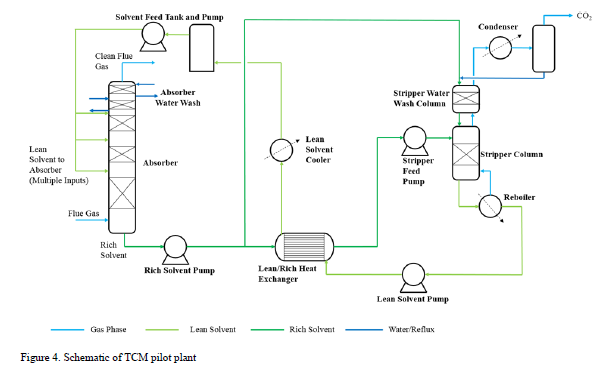

A schematic of the TCM pilot plant, on which the process model is based, is shown in Figure 4.

This process represents a typical post-combustion carbon capture system, with two notable process enhancements. The absorber tower consists of two 6-meter packed beds and one 12-meter bed for gas/solvent contacting. There are three inlets to the absorber for the CO2-lean solvent so that testing may be performed with either 12, 18, or 24 meters of packing. Moreover, a bypass system is included so that a fraction (~ 20%) of the CO2-rich solvent exiting the absorber is bypassed from the lean/rich heat exchanger and heated in the stripper water wash column by the vapor exiting the top of the stripper. This process configuration was implemented at TCM to reduce the required energy input to the reboiler. The flowsheet shown in Figure 4 is implemented in Aspen Plus V11, using the thermodynamic and kinetic models described in the previous sections. The absorber and stripper are modeled as rate-based columns with mass transfer and interfacial area models based on the work of Bravo et al. [14]; the liquid hold-up in the absorber column uses the model of Billet and Schultes [15]. The model of the absorber water wash was not included in this work because it was not needed for validation of the absorber/stripper loop but it will be developed in future work focused on prediction of amine emissions, for which discussion is forthcoming.

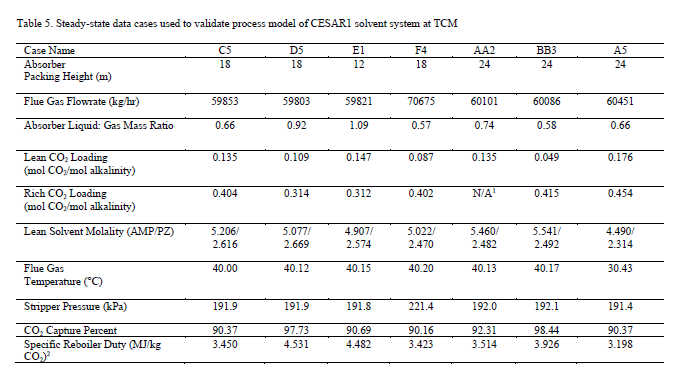

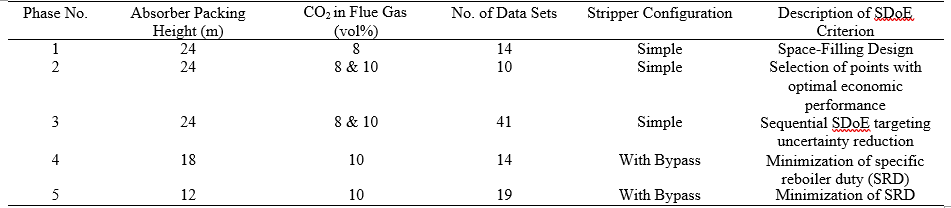

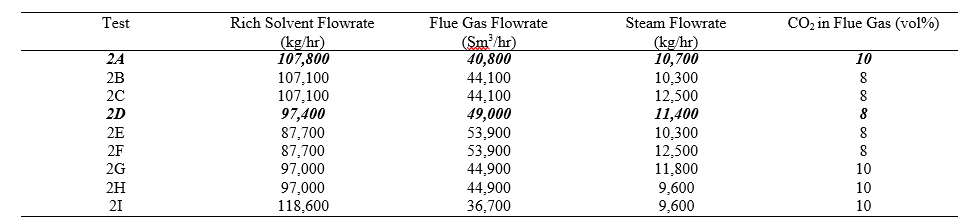

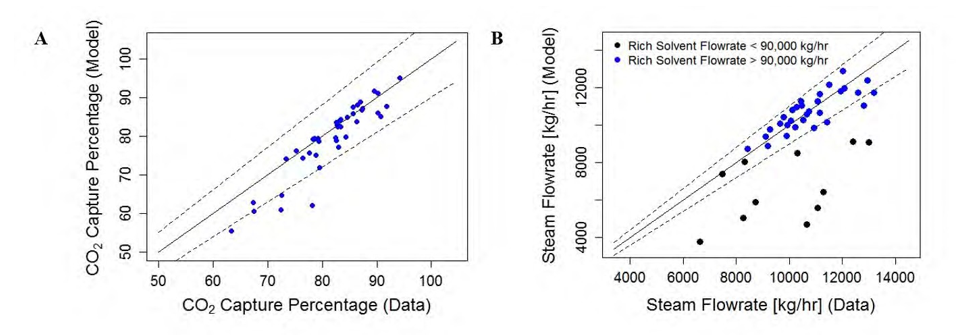

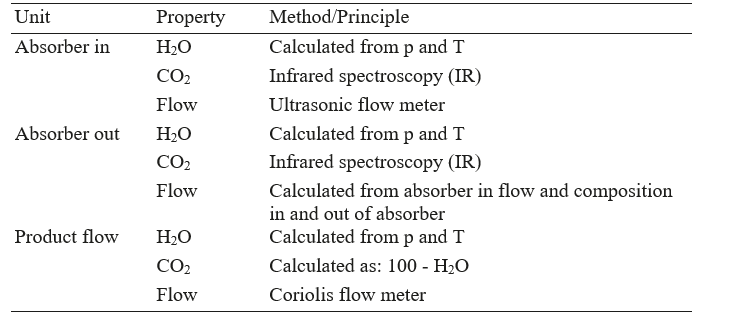

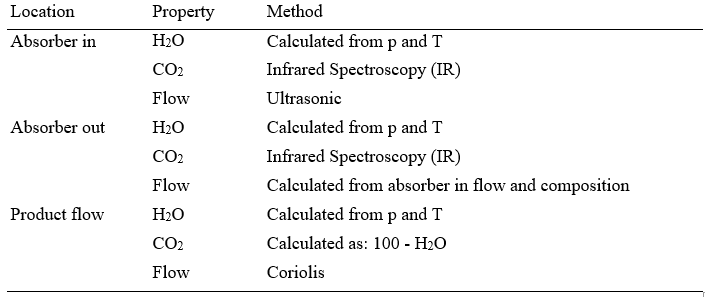

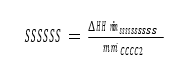

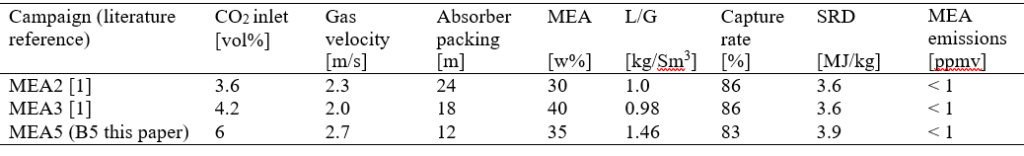

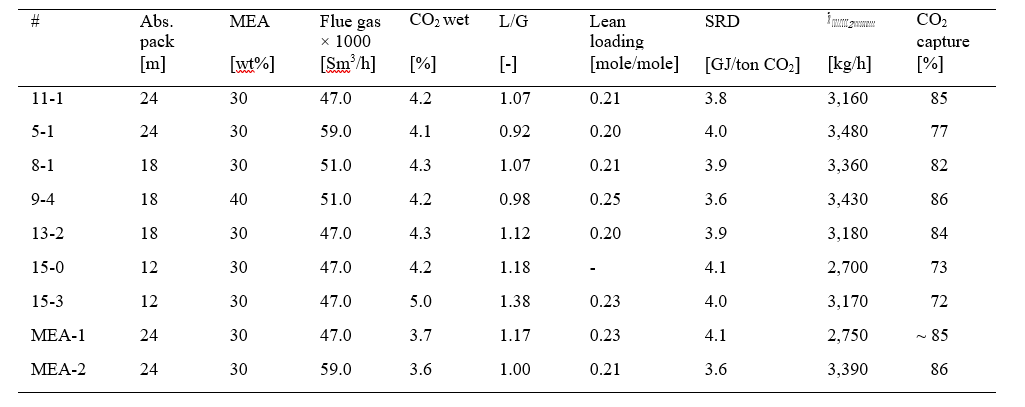

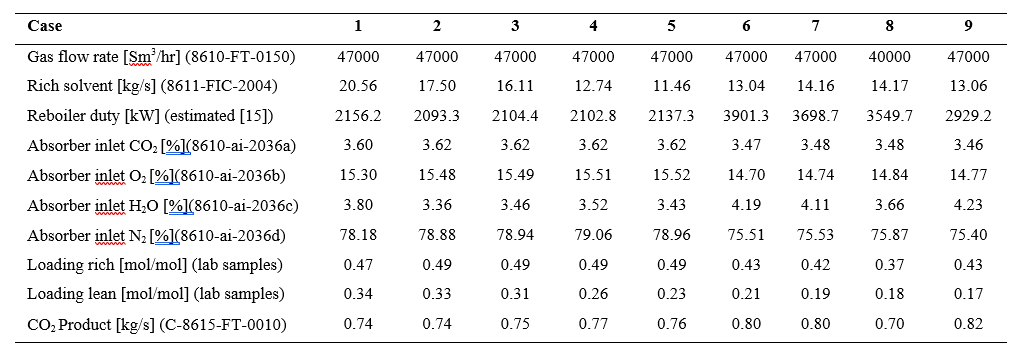

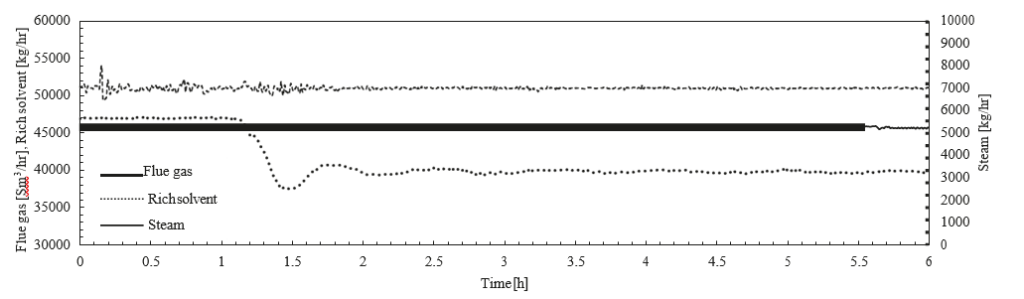

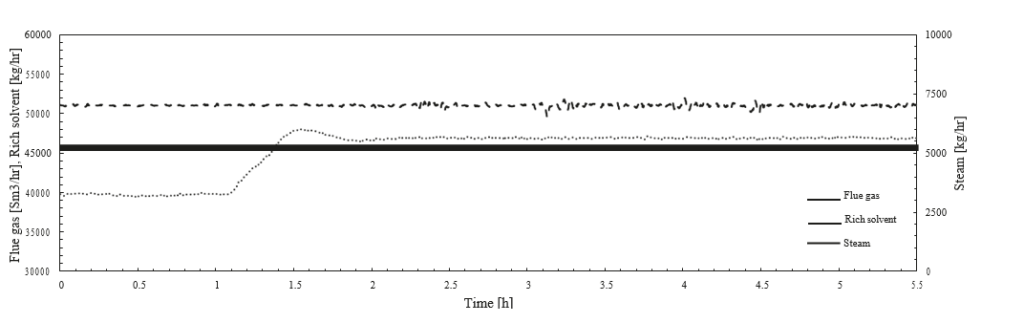

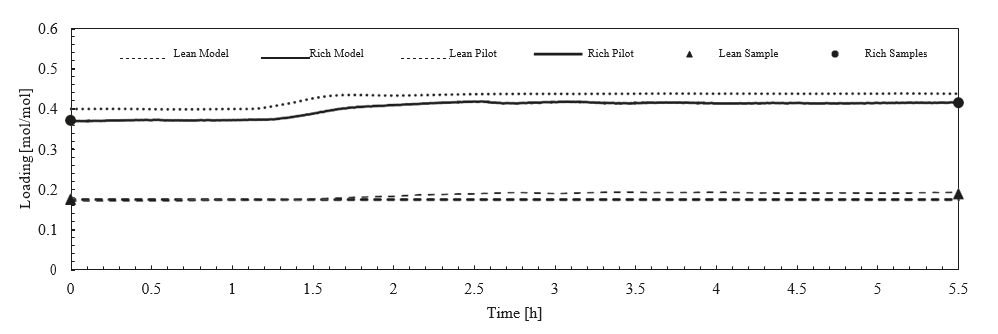

3. Model Validation

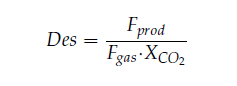

Seven steady-state data sets, collected at TCM during a test campaign in September–October 2019 sponsored by the Accelerating Low Carbon Industrial Growth through Carbon Capture, Utilisation, and Storage (ALIGN-CCUS) program [16], are used to validate the process model. Shown in Table 5, the overall data set includes substantial variation in process operating conditions, including absorber packing height and the flowrates of circulated solvent, flue gas, and reboiler steam. For all cases, natural gas-based combined cycle turbine flue gas, containing 3.5% by volume CO2, was used. It is also notable that the level of CO2 capture varies from 90–98.5%, while the approximate level of CO2 capture required for net-zero emissions for this flue gas source is approximately 99%.

2 Specific reboiler duty (SRD) is the ratio of the reboiler duty to the mass of CO2 captured – which is determined through a mass balance around the absorber

In Table 5, the CO2 loading is defined in terms of total alkalinity:

This is done for consistency with the liquid phase composition measurements at TCM. However, the convention used for CO2 loading in the context of thermodynamic model validation (Figures 1 – 2) is:

This convention follows that used in the sources for which thermodynamic data were obtained [6; 10 –11]. It can be shown that the two definitions of CO2 loading are related as follows:

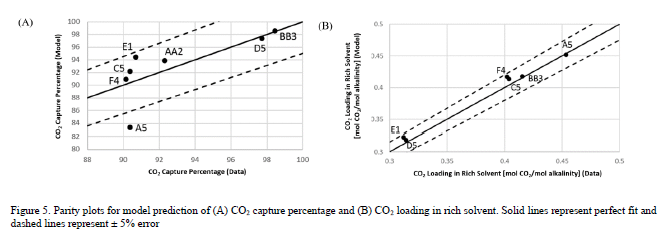

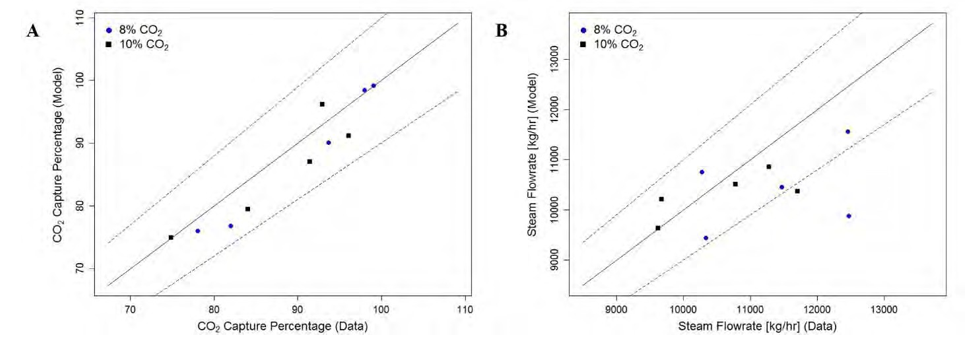

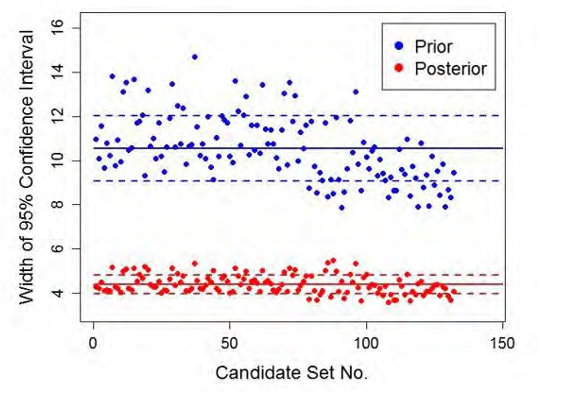

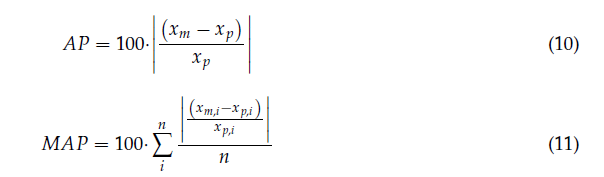

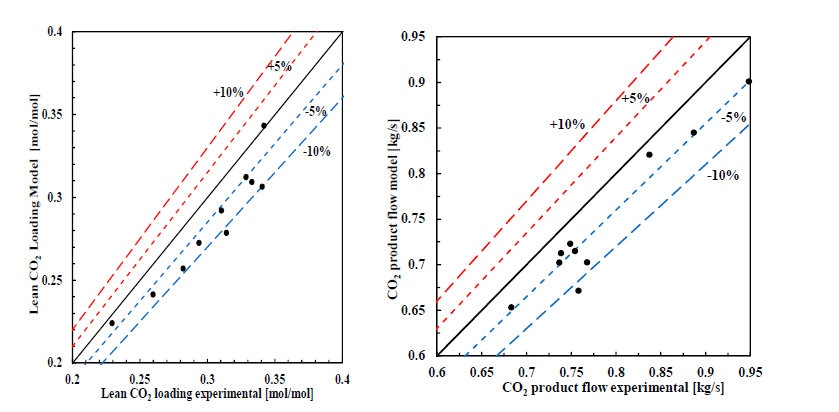

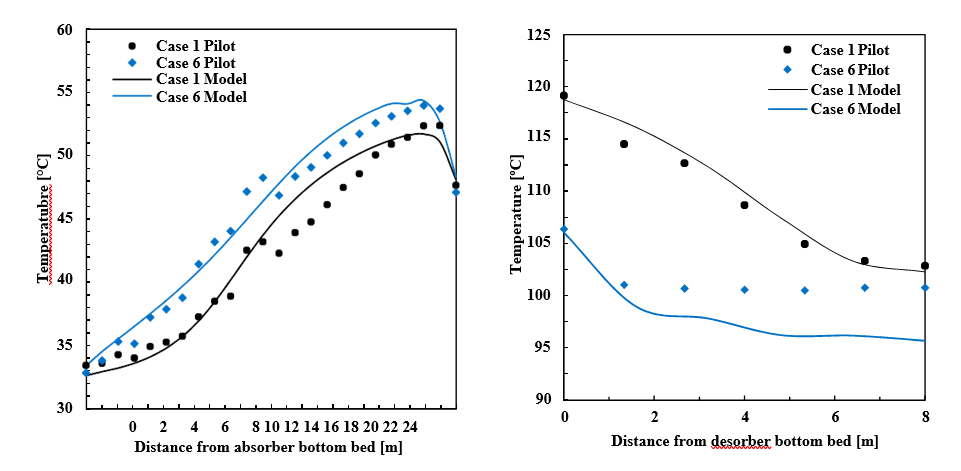

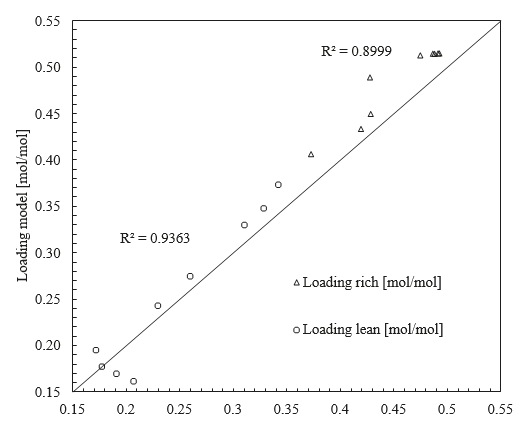

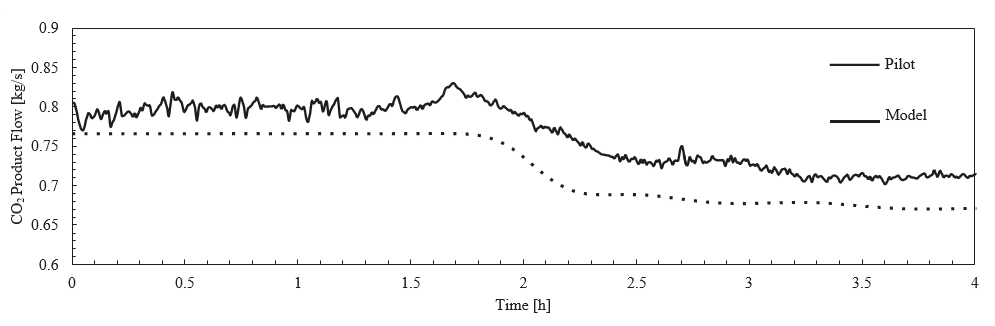

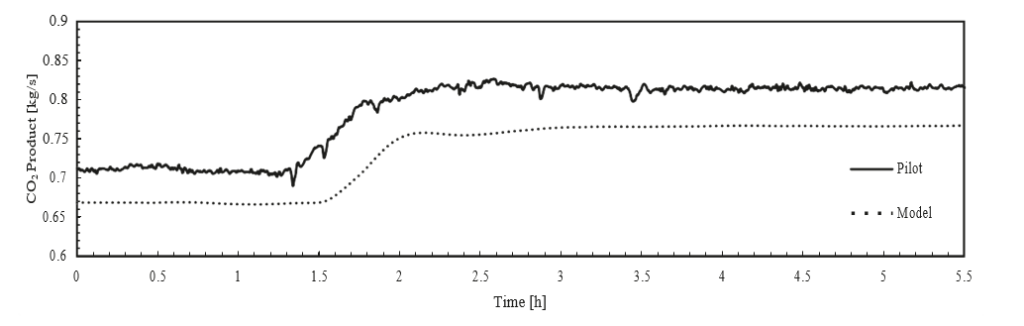

The process model of the TCM pilot plant with CESAR1 solvent system developed in this work is evaluated for all data cases. The absorber model performance is evaluated by comparing experimental values and model predictions of CO2 capture percentage and CO2 loading in the rich solvent exiting the absorber. A perturbation factor in the liquid holdup sub-model is included to minimize the error in the absorber model, although this assumption will be analyzed further through uncertainty quantification of the mass transfer, kinetic, and holdup sub-models in future work. Parity plots for the model predictions of the absorber output variables are shown in Figure 5.

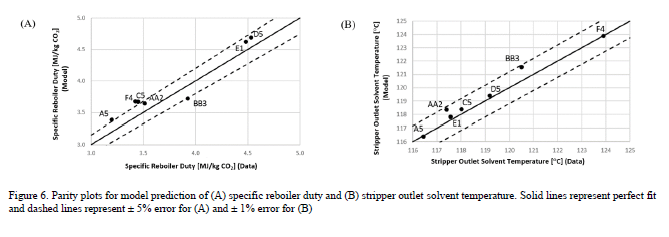

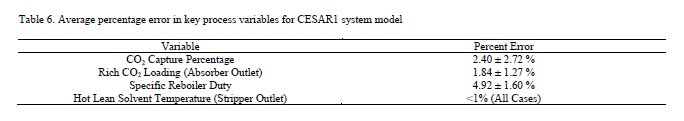

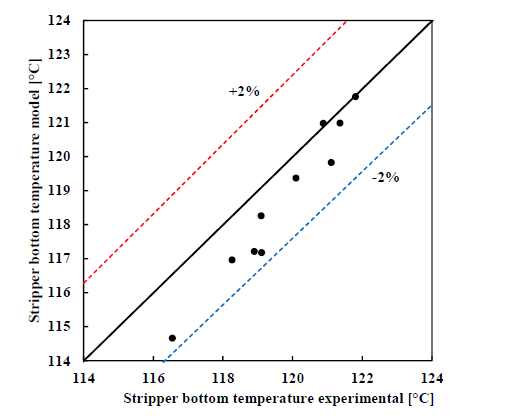

As shown in Figure 5, the model predicts the CO2 capture percentage and CO2 loading in the rich solvent within ±5 for most data cases, although the model seems to underpredict the percentage of CO2 capture for case A5. However, the model accurately predicts the CO2 loading in the rich solvent for this case, which suggests an inaccuracy in the mass balance closure for this case. The stripper model performance is evaluated through the specific reboiler duty, which is the ratio of the reboiler duty and the mass of CO2 captured, and the temperature of the lean solvent exiting the bottom of the column. Parity plots for the model predictions of the stripper output variables are shown in Figure 6. Moreover, Table 6 includes a summary of the percentage error in the model prediction of key process variables for the CESAR1 model.

Figure 6. Parity plots for model prediction of (A) specific reboiler duty and (B) stripper outlet solvent temperature. Solid lines represent perfect fit and dashed lines represent ± 5% error for (A) and ± 1% error for (B).

The specific reboiler duty is generally predicted with percentage error of ± 5% for all cases, and the percentage error in the prediction of the stripper outlet temperature is less than 1% for all cases.

4. Conclusions

In summary, a model was developed for the CESAR1 post-combustion carbon capture process at the TCM pilot plant for a flue gas source consistent with natural gas conditions. The model was validated with seven steady-state data sets, representing a variety of operating conditions and CO2 capture levels near the point of net-zero emissions (~ 99% capture for flue gas from natural gas combustion), and found to be predictive of key output variables for both the CO2 absorption and solvent regeneration processes. Ongoing and future work on the CESAR1 model will focus on analysis of the solution thermodynamics and reaction kinetics of the underlying sub-systems of the AMP-PZ-H2O-CO2 system (i.e., CO2-loaded aqueous PZ and AMP systems). While the thermodynamic models were deemed accurate for characterization of the absorber and stripper performance for the concentration of interest for the CESAR1 solvent system (5 m AMP, 2.5 m PZ), further analysis of the sub-systems would be required to ensure accuracy of the model for AMP–PZ blends of varying concentrations. Parametric UQ will be implemented on the key process sub-models, including thermodynamics, reaction kinetics, liquid holdup, and mass transfer/interfacial area to enable stochastic estimation of model performance at pilot scale. This will be essential for quantifying technical process risk associated with scale-up as well as estimating the economic performance prior to the deployment of CESAR1 as a plant-scale CCS system. In a separate effort under the Sustainable OPEration of post-combustion Capture plants (SCOPE) program the CESAR1 modeling framework will be expanded to include the absorber water wash section for quantifying the level of solvent emissions associated with the process. The SCOPE project [17], funded through the Accelerating CCS Technologies (ACT) program, is focused on supporting the development of technology for greenhouse gas emissions control through large scale deployment of effective emissions management tools and demonstration at CO2 capture pilot plants. Accurate prediction of amine emissions requires thermodynamic models that are valid for solutions with much lower amine concentrations than those encountered in the absorber/stripper loop. One of the goals of SCOPE is to fill the current gap in the literature for vapor-liquid equilibria data for solutions of low amine concentration, thus enabling the development of more accurate amine emissions models. Finally, the CESAR1 process model will be released as part of the open-source CCSI Toolset in the near future to accompany the existing baseline aqueous MEA model for use by researchers for such analyses including, but not limited to, multi- scale modeling and validation, techno-economic analysis, and rigorous comparison of solvent-based CO2 capture systems.

References

[1] Miller DC, Syamlal M, Mebane DS, Storlie C, Bhattacharyya D, Sahinidis NV, Agarwal D, Tong C, Zitney SE, Sarkar A, Sun X, Sundaresan S, Ryan E, Engel D, Dale C, 2014. Carbon capture simulation initiative: a case study in multiscale modeling and new challenges. Annu. Rev. Chem. Biomol. Eng. 5: 301-323.

[2] Morgan JC, Chinen AS, Omell B, Bhattacharyya D, Tong C, Miller DC, Buschle B, Lucquiaud M, 2018. Development of a rigorous modeling framework for solvent-based CO2 capture: Part 2: steady-state validation and uncertainty quantification with pilot plant data. Ind. Eng. Chem. Res. 57: 10464-10481.

[3] Morgan JC, Chinen AS, Anderson-Cook C, Tong C, Carroll J, Saha C, Omell B, Bhattacharyya D, Matuszewski M, Bhat KS, Miller DC, 2020. Development of a framework for sequential Bayesian design of experiments: application to a pilot-scale solvent-based CO2 capture process. Appl. Energy. 262: 114533.

[4] Morgan JC, Omell B, Matuszewski M, Miller DC, Shah MI, Benquet C, Knarvik ABN, de Cazenove T, Anderson-Cook CM, Ahmed T, Tong C, Ng B, Bhattacharyya D, 2021. Application of sequential design of experiments (SDoE) to large pilot-scale solvent-based CO2 capture process at Technology Centre Mongstad (TCM). Proceedings of the 15th International Conference on Greenhouse Gas Control Technologies. 15-18 March 2021, Available at SSRN: https://ssrn.com/abstract=3811695

[5] Putta KR, Saldana D, Campbell M, Shah MI, 2022. Development of CO2 capture process cost baseline for 555 MWe NGCC power plant using standard EA solution. Proceedings of the 16th International Conference on Greenhouse Gas Control Technologies. 23 – 27 October 2022, Lyon, France.

[6] Brúder P, Grimsvedt A, Mejdell T, Svendsen HF, 2011. CO2 capture into aqueous solutions of piperazine activated 2-amino-2-methyl-1- propanol. Chem. Eng. Sci. 66: 6193-6198.

[7] Cousins A, Feron P, Hayward J, Jiang K, Zhai R, 2019. Further Assessment of Emerging CO2 Capture Technologies for the Power Sector and their Potential to Reduce Costs: IEAGHG Technical Report. Available at http://documents.ieaghg.org/index.php/s/YKm6B7zikUpPgGA?path=%2F2019%2FTechnical%20Reports

[8] Aspen Plus documentation, 2014. Rate-based model of the CO2 capture process by PZ using Aspen Plus. Aspen Technology Inc, Cambridge MA.

[9] Aspen Plus documentation, 2014. Rate-based model of the CO2 capture process by AMP using Aspen Plus. Aspen Technology Inc, Cambridge MA.

[10] Hartono A, Ahmad R, Svendsen HF, Knuutila HK, 2021. New solubility and heat of absorption data for CO2 in blends of 2-amino-2-methyl- 1-propanol (AMP) and piperazine (PZ) and a new eNRTL model representation. Fluid Phase Equilib. 550: 113235.

[11] Xie Q, Aroonwilas A, Veawab A, 2013. Measurement of heat of CO2 absorption into 2-amino-2-methyl-1-propanol (AMP)/piperazine (PZ) blends using differential reaction calorimeter. Energy Procedia. 37: 826-833.

[12] Chen CC, Evans LB, 1986. A local composition model for the excess Gibbs energy of aqueous electrolyte systems. AIChe J. 32(3): 444-454.

[13] Morgan JC, Chinen AS, Omell B, Bhattacharyya D, Tong C, Miller DC, 2017. Thermodynamic modeling and uncertainty quantification of CO2-loaded aqueous MEA solutions. Chem Eng Sci. 168: 309-324.

[14] Bravo JL, Rocha JA, Fair JR, 1985. Mass transfer in gauze packings. Hydrocarbon Proc. 64(1):91.

[15] Billet R, Schultes M, 1993. Predicting mass transfer in packed columns. Chem Eng Technol. 16, 1-9.

[16] Benquet C, Knarvik A, Gjernes E, Hvidsten OA, Kleppe ER, Akhter S, 2021. First process results and operational experience with CESAR1 solvent at TCM with high capture rates (ALIGN-CCUS project). Proceedings of the 15th International Conference on Greenhouse Gas Control Technologies. 15-18 March 2021, Abu Dhabi, UAE.

[17] Kvamsdal HM, van Os P, Moser P, Korre A, Martin A, Matuszewski MS, Gupta NC, Khakharia P, McNally C, 2022. SCOPE: an ERA-NET ACT project on sustainable operation of post-combustion capture plant. Proceedings of the 16th International Conference on Greenhouse Gas Control Technologies. 23 – 27 October 2022, Lyon, France.

Disclaimer

This project was funded by the Department of Energy, National Energy Technology Laboratory an agency of the United States Government, through a support contract. Neither the United States Government nor any agency thereof, nor any of its employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Acknowledgements

The authors graciously acknowledge funding from the U.S. Department of Energy, Office of Fossil Energy and Carbon Management, through the Carbon Capture Program.

The authors gratefully acknowledge the staff of TCM DA, Gassnova, Equinor, Shell, and TotalEnergies for their contribution and work at the TCM DA facility. The authors also gratefully acknowledge Gassnova, Equinor, Shell, and TotalEnergies as the owners of TCM DA for their financial support and contributions.

Application of Sequential Design of Experiments (SDoE) to Large Pilot-Scale Solvent-Based CO2 Capture Process at Technology Centre Mongstad (TCM) (2021)

Joshua C. Morgana,b,*, Benjamin Omella, Michael Matuszewskia, David C. Millera, Muhammad Ismail Shahc, Christophe Benquetc, Anette Beate Nesse Knarvikc, Thomas de Cazenovec, Christine M. Anderson-Cookd, Towfiq Ahmedd, Charles Tonge, Brenda Nge, Debangsu Bhattacharyyaf

aNational Energy Technology Laboratory, 626 Cochrans Mill Road, P.O. Box 10940, Pittsburgh PA 15236-0940, USA b NETL Support Contractor, 626 Cochrans Mill Road, P.O. Box 10940, Pittsburgh PA 15236-0940, USA cCO2 Technology Centre Mongstad, Mongstad 71, 5954 Mongstad, Norway dLos Alamos National Laboratory, P.O. Box 1663, Los Alamos NM 87545, USA eLawrence Livermore National Laboratory, 7000 East Ave, Livermore CA 94550, USA fWest Virginia University, Department of Chemical and Biomedical Engineering, 1306 Evansdale Drive, P.O. Box 6102, Morgantown WV 26506-6102, USA *Corresponding author

Abstract

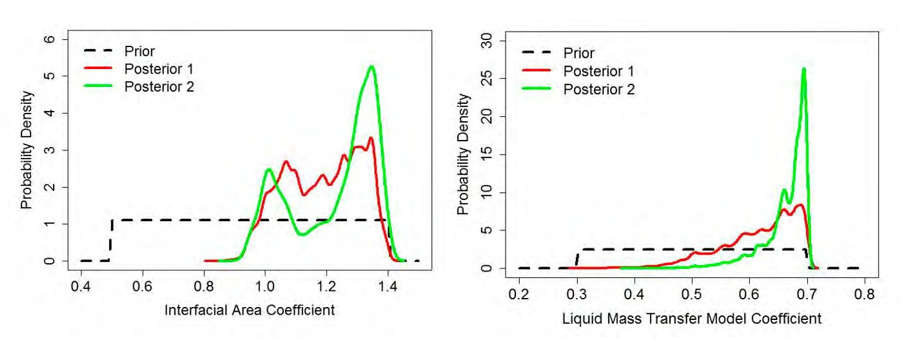

The United States Department of Energy’s Carbon Capture Simulation for Industry Impact (CCSI2) program has developed a framework for sequential design of experiments (SDoE) that aims to maximize knowledge gained from budget- and schedule- limited pilot scale testing. SDoE was applied to the planning and execution of campaigns for testing CO2 capture systems at pilot- scale in order to optimally allocate resources available for the testing. In this methodology, a stochastic process model is developed by quantifying the parametric uncertainty in submodels of interest; for a solvent-based CO2 capture system, these may include physical properties and equipment performance submodels (e.g., mass transfer, interfacial area). This uncertainty is propagated through the full process model, over variable operating conditions, for estimating the resulting uncertainty in key model outputs (e.g., percentage of CO2 capture, solvent regeneration energy requirement). In developing a data collection plan, the predicted output uncertainty is incorporated into an algorithm that seeks simultaneously to select process operating conditions for which the predicted uncertainty is relatively high and to ensure that the entire space of operation is well represented. This test plan is then used to guide operation of the pilot plant at varying steady-state conditions, with resulting process data incorporated into the existing model using Bayesian inference to refine parameter distributions. The updated stochastic model, with reduced parametric uncertainty from data collected, is then used to guide additional data collection, thus the sequential nature of the experimental design.

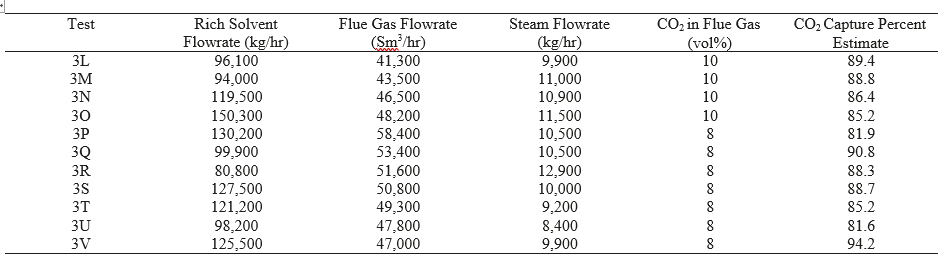

The SDoE process was implemented at the pilot test unit (12 MWe in scale) at Norway’s Technology Centre Mongstad (TCM) in a summer 2018 test campaign with aqueous monoethanolamine (MEA). During the test campaign, the varied operating conditions included the flowrates of circulated solvent, flue gas, and reboiler steam and the CO2 concentration in the flue gas. The process data were used to update probability distributions of mass transfer and interfacial area parameters of a stochastic process model developed by the CCSI2 team. Two iterations of the SDoE process were executed, resulting in the uncertainty in model predicted CO2 capture percentage decreasing by an average of 58.0 ± 4.7% over the full input space of interest. This work demonstrates the potential of the SDoE process for model refinement through reduction in process model parametric uncertainty, and ultimately risk in scale-up, in CO2 capture technology performance.

1. Introduction

The United States Department of Energy’s Carbon Capture Simulation for Industry Impact (CCSI2) program is a collaboration of national laboratories, universities, and industrial organizations that provides research and development support for novel CO2 capture technologies with the objective of reducing risk and accelerating their commercialization. These efforts involve continuing advancements in and applications of the open-source toolset1 developed as part of its predecessor project, the Carbon Capture Simulation Initiative (CCSI). The CCSI Toolset includes a suite of computational tools and models with the overarching goal of accelerating the development, deployment, and scale-up of CO2 capture technologies. The toolset includes a rigorous process model, implemented in Aspen Plus®, of the aqueous monoethanolamine (MEA) solvent system, which is the industrial standard for solvent- based CO2 capture. This model includes quantification of parametric uncertainty for solvent physical property models such as viscosity, density, and surface tension [1], the thermodynamic framework [2], and packing-specific models such as mass transfer, interfacial area, and hydraulics [3]. These submodels combine with a full process model that was validated with process data from the 0.5 MWe pilot test unit at the National Carbon Capture Center (NCCC) in 2014 [4]. In 2017, an additional test campaign for the aqueous MEA system was held at NCCC, incorporating the CCSI2 framework for SDoE. In this methodology, the existing process model is leveraged to inform collection of data that are subsequently used to refine the model and modify the test plan accordingly [5,6]. Over two iterations of the SDoE process, parametric distributions for process submodels were refined through experimental observations of absorber CO2 capture percentage, resulting in an average uncertainty reduction of approximately 50% for the model prediction of CO2 capture percentage throughout the input space of interest.

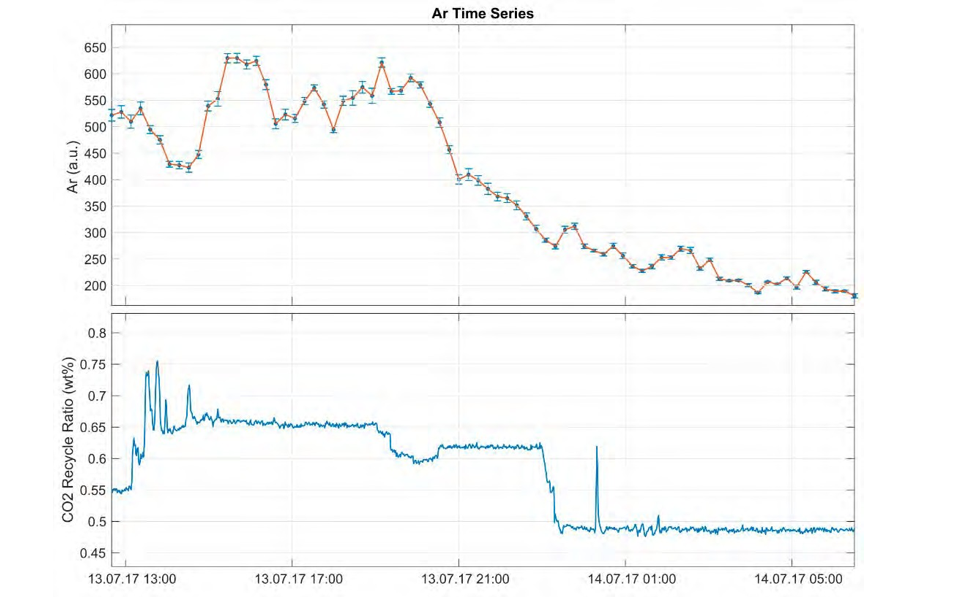

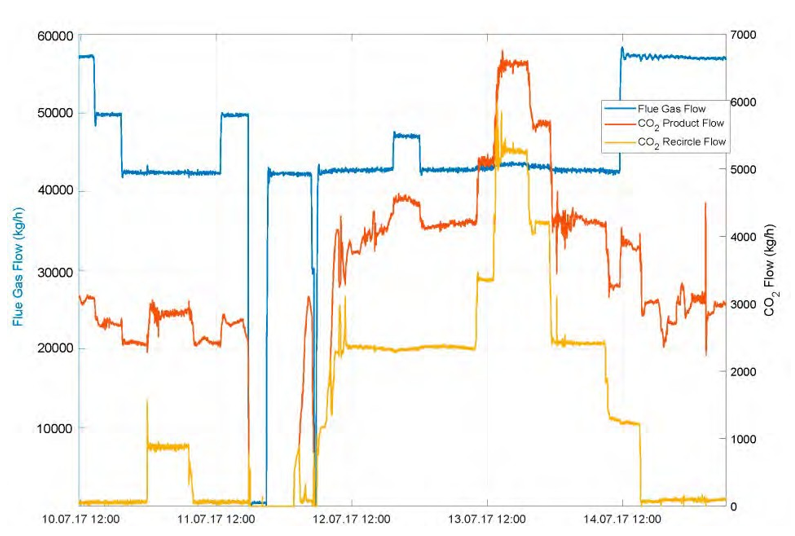

The CCSI aqueous MEA process model was scaled up to 12 MWe for consistency with the pilot test unit at Norway’s Technology Centre Mongstad (TCM) and was used in the planning and execution of a test campaign at TCM in summer 2018. TCM is one of the world’s largest facilities for testing carbon capture technologies, and previous test results with the MEA solvent system have been reported in the open literature [7-12], including variation in many process variables and both steady-state and dynamic operation. The pilot plant at TCM notably has two sources of flue gas: combined cycle gas turbine (CCGT) based heat and power plant (CHP), with ~3.5 vol% CO2, and residual fluidized catalytic cracker (RFCC) unit, with ~13-14 vol% CO2. The TCM plant also contains two stripper columns, each designed for process operation with one of the flue gas sources. This work focused on collecting additional data for the MEA process at TCM with variation in the flowrates of solvent, flue gas, and reboiler steam, the concentration of CO2 in the flue gas, the packing height of the absorber, and the stripper configuration. During the first three weeks of the test campaign, which are the primary focus of this paper, the SDoE framework was used to guide the collection of process data using the existing MEA process model and multiple test objectives. The data were used to update the model by refining the distributions of parameters in the mass transfer and interfacial area submodels, ultimately resulting in a reduction of predicted uncertainty in the CO2 capture percentage from 10.5 ± 1.5% to 4.4 ± 0.4%, or an average reduction of 58.0 ± 4.7%, over the full input space of interest. In the final two weeks of the campaign, data were collected for a modified process configuration in which the packing height of the absorber was reduced to 18 meters, and eventually 12 meters, and the stripper configuration was modified so that a fraction (~20%) of the rich solvent exiting the absorber bypasses the lean-rich heat exchanger and is heated in the water wash of the stripper. This work, along with the previous test campaign at NCCC, demonstrates the potential of the SDoE methodology for refining predictions of stochastic process models through strategic data collection. The reduction of model uncertainty effectively reduces expected risk in process design and operation, thus improving confidence when predicting process performance and conducting economic analyses.

2. Methodology

2.1 SDoE Methodology

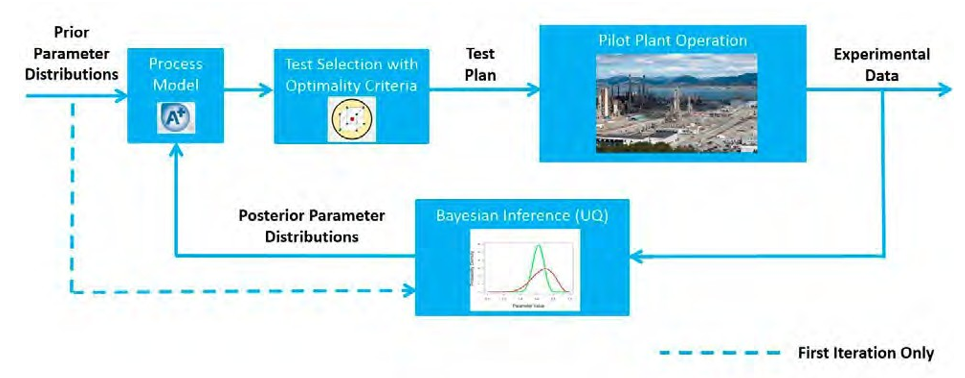

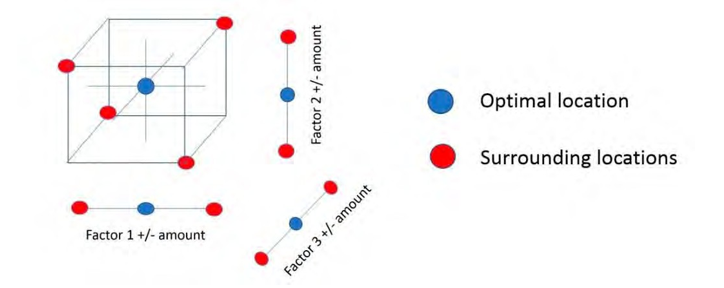

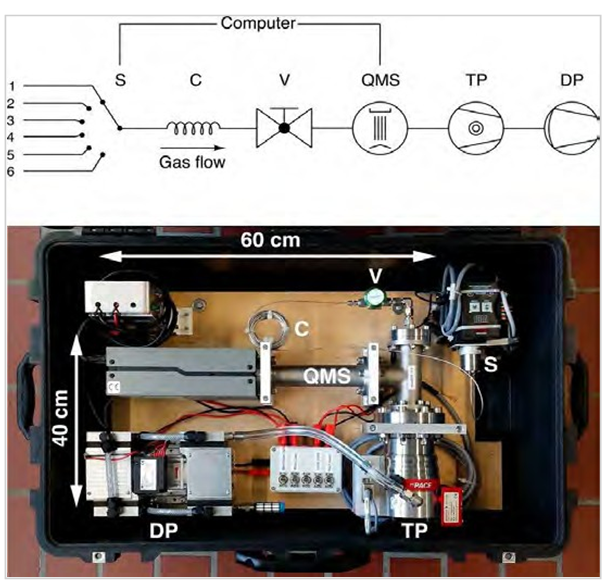

The SDoE process developed by CCSI2 uses a stochastic model, with parametric uncertainty quantified in the submodels, to inform collection of process data in order to maximize the value of data obtained during a test campaign. Moreover, it provides a framework for directly reducing uncertainty in model prediction of capture rates based on new process knowledge gained from data collection. The SDoE process is represented schematically in Fig. 1.

Fig. 1. Schematic representation of SDoE methodology.

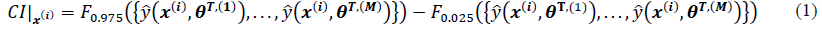

As shown in Figure 1, a priori probability distributions of submodel parameters are propagated through a process model, denoted as 𝑦(𝒙, 𝜽, 𝜽∗), where 𝒙 is a set of input variables that can be manipulated in plant operation and 𝜽 and 𝜽∗ are sets of model parameters. These sets differ in that 𝜽 contains parameters for which uncertainty is reduced over the course of executing the SDoE methodology whereas 𝜽∗ has parameters with irreducible uncertainty based on the type of data collected. For the example of a solvent-based CO2 capture system, 𝜽 includes process specific parameters from submodels such as mass transfer or interfacial area that may be informed through collection of plant data (e.g. CO2 capture percentage in the absorber column). Conversely, 𝜽∗ includes parameters from physical property submodels, for which uncertainty is readily estimated through direct measurements of the corresponding properties and cannot reasonably be informed from plant level data. If the process model y is sufficiently complex, it may be necessary to replace it with a surrogate model, denoted as 𝑦̂(𝒙, 𝜽, 𝜽∗), developed and validated over the full input space. For a given point in the input space, a confidence interval for the model prediction are computed by propagating the uncertainty in the full set of parameters (𝜽𝑻 = [𝜽 𝜽∗]) through the surrogate model. The 95% confidence interval, estimated by taking a sample of size M over the full parameter space (𝜽𝑻,(𝒋), ∀ 𝑗 = 1, … 𝑀), is given as: