Real-time monitoring of 2-amino-2-methylpropan-1-ol and piperazine emissions to air from TCM post combustion CO2 capture plant during treatment of RFCC flue gas

Audun Drageseta*, Øyvind Ullestada,b, Eirik Romslo Kleppea,b, Blair McMastera,c, Magnus Aronssona,b, Jonas-Andre Olsena,b

aTechnology Centre Mongstad (TCM), 5954 Mongstad, NorwabEquinor ASA, PO Box 8500, 4035 Stavanger, Norway

cTotalEnergies EP Norge AS, Finnestadveien 44, Dusavik, 4029 Stavanger, Norway

Abstract

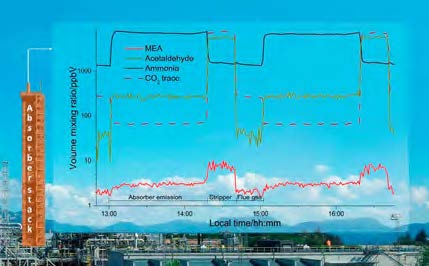

Monitoring and understanding the emissions of pollutants is vital for safe implementation of new industries. To ensure the safe adoption of amine-based post-combustion carbon capture to combat climate change, reliable and accurate monitoring technologies must be available for commercial projects to ensure they can monitor and control any new pollutants that might results from capturing CO2 from an industrial flue gas. As a test site for carbon capture technologies, Technology Centre Mongstad (TCM) monitors pollutants emitted in the flue gas via online sampling and analysis as per regulatory requirements. This work presents the first results from a newly installed ion-molecule reaction mass spectrometer (IMR-MS) that was employed during a test campaign with the amine solvent blend of 2-amino-2-methylpropan-1-ol (AMP) and piperazine (PZ) to monitor trace pollutants in the emitted flue gas. The primary pollutants were monitored and reported in real time in the range from 100 ppb (parts per billion) to 10 ppm (parts per million) and compared with extractive isokinetic sampling during a test campaign with an oil refinery cracker gas. The instrument allowed for real-time trending of the amine pollutants AMP and PZ in ppb range, which is the expected range required by regulators for some full-scale plants.

1. Introduction

Decarbonizing heavy industries is key for achieving the carbon mitigation goals outlined in the IPCC-6 report [1]. Amine-based carbon capture is among the most mature technologies for decarbonizing existing industrial point sources for CO2 emissions. Technology Centre Mongstad (TCM) have operated and demonstrated both non-proprietary and proprietary amine solvents for post-combustion carbon capture (PCCC) since 2012 [2]. TCM is located on the west coast of Norway in the vicinity of Equinor’s oil refinery at Mongstad. With access to two distinctly different industrial flue gases: combined-cycle gas turbine (CCGT)-based combined-heat-and-power plant (CHP) and RFCC (Residual fluid catalytic cracker) and the ability to manipulate these flue gases through air dilution and recycling of CO2, TCM can assess solvent technologies under conditions that are representative of multiple industries emissions [3]. Among the main objectives of TCMs test campaigns is to reduce the risk (economic and environmental) for commercial application and full-scale deployment of Carbon Capture and Storage (CCS). Key among the test campaigns conducted

* Corresponding author. Tel.: +47 9592 5273, E-mail address: Audun.drageset@tcmda.com

at TCM are the open test campaigns with non-proprietary solvents like aqueous 2-aminoethan-1-ol (commonly known as Monoethanolamine or MEA) and the aqueous blend of 2-amino-2-methylpropan-1-ol (AMP) and Piperazine (PZ), also known as CESAR1. Data and learnings from these campaigns can be disseminated in line with TCMs purpose to ensure safe technology adoption to combat climate change.

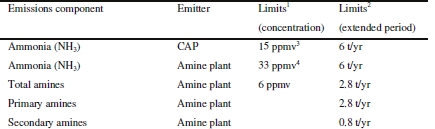

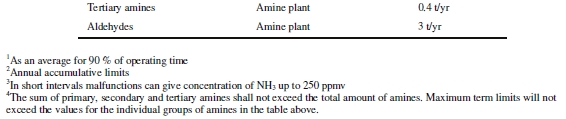

The test activities at TCM must be conducted within the framework of an emission permit [4]. The permit regulates aspects of the plant operation, among them emission to air and sets restrictions on components and their concentration. During the CO2 capture process trace amounts of contaminants are introduced to the treated gas emitted to air. Common pollutants are amines and volatile degradation products from the process like aldehydes, ketones and ammonia. Of particular concern is the class of compounds known as Nitramines and Nitrosamines, as these are known mutagenic agents and can cause cancer with prolonged exposure. In addition to direct process emissions, amines generate these compounds through photochemical reactions in the atmosphere [5]. Thus, the combination of stack emission monitoring and dispersion modelling is used to ensure the load to local environment (air and water) are within acceptable safety margins to safeguard public health and avoid damaging local ecosystems. TCM is required by the regulators to conduct continuous real-time monitoring of emissions and similar requirements may be imposed on full- scale plants in Norway and the rest of Europe. Industrial emission monitoring instruments and methods will therefore be important for full scale adoption of amine-based carbon capture. Fourier transformed infrared spectroscopy (FTIR) has been the primary instrument for real-time reporting of emissions for plant operation at TCM, but the quantification limit has been in the range of 0.5-1 ppm [2c]. Instruments with lower limits are required as the emission limit for some plants can be 1 ppm or lower [6]. Proton Transfer Reaction Time of Flight Mass spectrometry (PTR-TOF-MS) have been demonstrated in monitoring applications at TCM down to single digit ppb levels [7], however at time of writing the instrument results are not available in real-time for plant operation as the raw results recorded by the instrument require post-processing by skilled personnel. Herein we present results from a new Ion-Molecule Reaction Mass spectrometer (IMR-MS) tested during the 2020 campaign with an open solvent mixture of AMP and PZ.

2. Experimental section

2.1 Amine plant and operational conditions

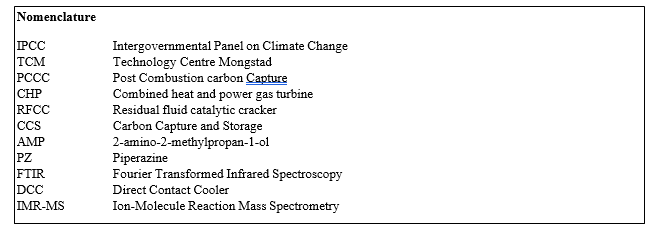

TCM operates a generic amine plant built and designed by Aker Solutions and Kværner with a flue gas capacity up to 60 000 Sm3/h and which has previously been described in the literature, hence only a description of the plant configuration is disclosed below [2]. The data presented in this work is from a test period of optimized plant configuration with the RFCC flue gas (14 vol% CO2) and a solvent mixture of AMP (29 wt%) and PZ (11 wt%). The plant was operated with 18-meter packing height and a flue gas flow rate of 35 000 Sm3. The plant was optimized to reduce aerosol emissions by (1) removal of acidic sulfuric aerosols from the flue gas via pH regulation of the Direct Contact Cooler (DCC) (NaOH injection to keep pH 8) [8], (2) Brownian diffusion filter [3b] to further reduce particle count and (3) a temperature profile adjusted to promote aerosol growth and capture in the first two water washes. The plant configurations and process conditions are summarized in Table and Figure 1, additional information and overall test objectives of the campaign are available in the literature [9].

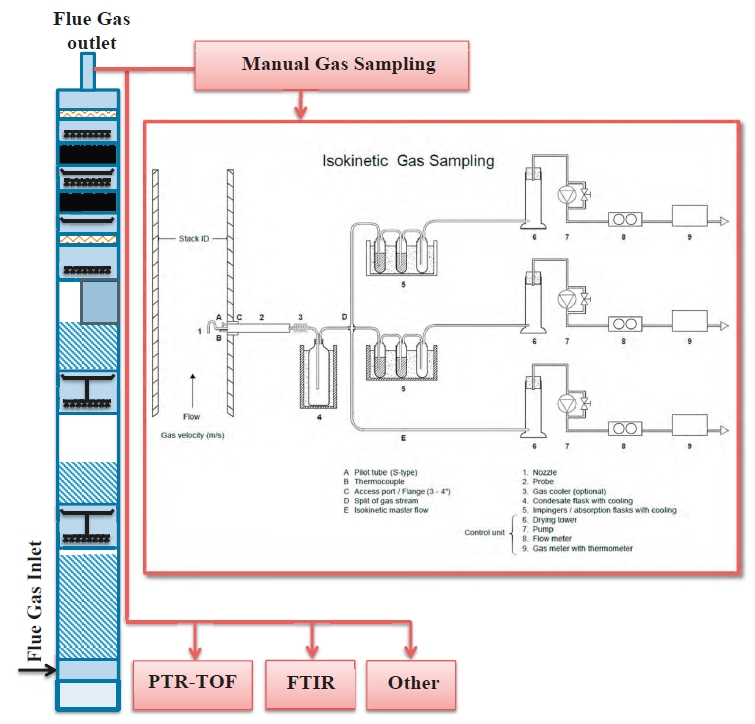

2.2 Absorber stack emission sampling

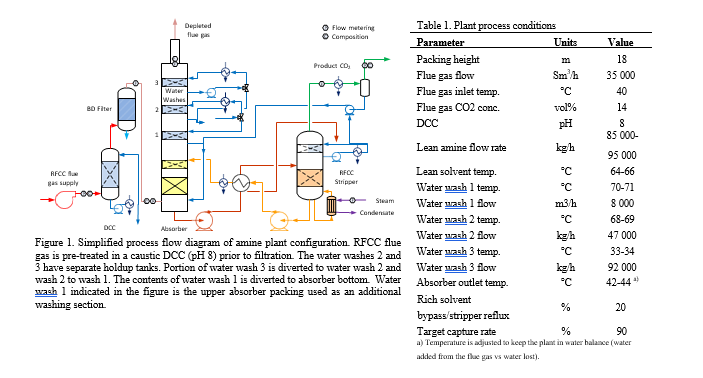

The RFCC flue gas contain acidic aerosols. Such aerosols will promote amine emissions to air, as amines are dissolved in the aerosol droplets as they travel through the absorber [10]. To acquire representative samples from such an emission point one must account for the aerosol momentum [11]. Key considerations are: (1) selection of the sample probe shape and placement, (2) the sampling rate and conditioning of the sample and (3) its transport. As a test site TCM have additional needs with respect to gas sampling and analysis for R&D applications and have therefore 3 separate sample points with comparable probes and location (Gooseneck, Paul Gothe, Heated combination probe, Version B, S-Pitot tube) (see Figure 2). Isokinetic extractive samples are collected via a cold sample system (see section 2.4) while online systems use a heated sample system (see Figure 3). The heated gas sampling system at TCM is designed to reduce measurement bias when the gas contains aerosols. The sample gas is collected via a gooseneck sample probe (SP2) heated to 120 °C. In addition, a fast-loop system is configured to sample the stack at 1 m3/h, resulting in a sampling velocity 10-11 m/s that mimics isokinetic sampling conditions. By mimicking isokinetic sampling conditions one aim to get a representative sample of the aerosols in the gas. The fast loop is equipped with a vaporizer (Elmess thermo systems, Electrical flow heater, 35 – 200 °C with modified temperature control) where the sample is heated to elevated temperature (120 °C), disrupting and evaporating the aerosols to the gaseous phase. An inline heated filter (3-micron pore size) removes solid particulates from the gas stream. A sample stream of the fast-loop sample gas is transported through an approximately 100-meter sample line (O’Brien, TRACEPAC®, TrueTube EPS, Electropolished SilcoNet tubing, 1/4 inch) to an environmentally controlled analyser-house at ground level for easy access to the analytical instruments. The final heated samples system (SP3) is connected to an analyser

house at the top of the absorber via a 10-meter heated sample line and is predominantly used for research applications [7].

2.3 Mass spectrometry system

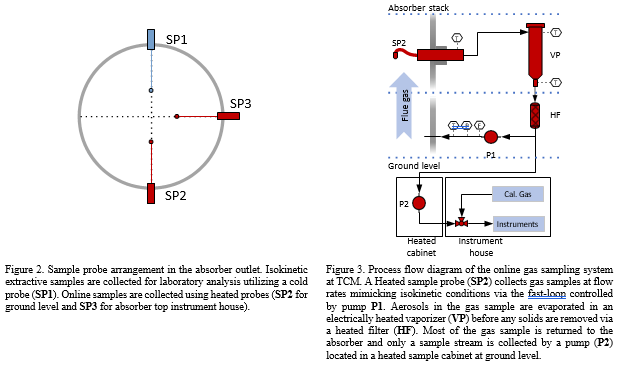

This work utilizes a commercially available Ion-Molecule Reaction Mass spectrometer (IMR-MS) (AirSense, V&F Analyse- und Messetchnik GmbH, Austria) [12]. Soft chemical ionisation of the sample gas is favourable to respectively reduce and minimise fragmentation of the parent molecules in a complex mixture like a flue gas containing trace volatile organic compounds. To achieve this the instrument utilises different gasses with varying ionisation energy to ionise the sample, in this work Hg (10.44 eV) and Xe (12.13 eV) ionisation modes were used. This can allow for the separation of ions with similar mass if their ionisation potential is different. The IMR-MS was installed in the ground level analyser house with the sampling system described in Figure 3. The instrument was calibrated using aqueous solutions and a calibration gas generator (HOVACAL, Digital 312-MF, IAS GmbH, Germany) with nitrogen as a carrier gas (Table 2.). The mass spectra of each component were recorded and used in selection mass signal for monitoring (see Figure 4). AMP exhibited water cross sensitivity in addition to mass fragment overlap with PZ, these effects were minimized after the implementation of enhancements (online calculations to correct for cross interaction between components and non-linear behaviour) in the instrument software suite (V&F Viewer Software, version 2.4). An overview of compound selection and enhancements are found in Table 2.

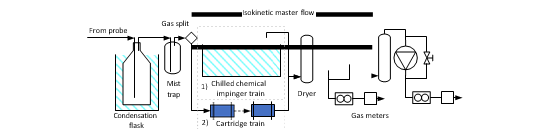

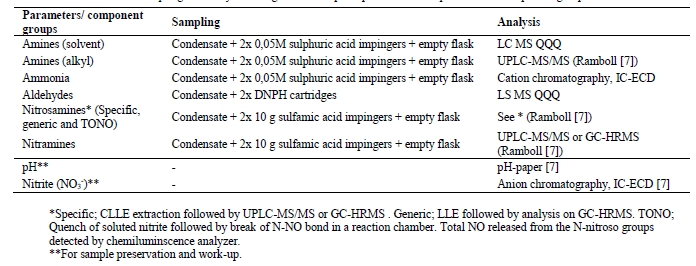

2.4 Extractive gas sampling

The extractive sampling equipment, control unit (Paul Gothe GmbH) and sample train was assembled at the sample location by TCM laboratory personnel. The probe and sample lines were at ambient temperature with a sample train consisting of three capture modes: (1) Condensation flask which cools down the gas to collect condensable, (2) Mist trap consisting of an empty impinger flask containing a 1 mm jet generating approximate gas speed of 80 m/s that that collects medium/large aerosols and (3) absorption flasks containing sulfuric acid (0.05M) and a 1mm jet captures small aerosols, gaseous amines and ammonia in the acidic solution (see Figure 5). Generally sampling time is 1-2 hours. Samples are analysed using a Dionex Integrion HPIC System (model ICS-5000, Thermo Fisher Scientific) which included an IonPac CS19 column and an IonPac CG19 guard column and MS detector (Thermo Fisher, ISQ EC Mass spectrometer). Aldehydes and acetone are sampled using a similar sample train where the absorption bottles are exchanged with two silica cartridges (Sep-Pak® DNPH-Silica Cartridge, 800 mg). Sample time is considerably shorter as cartridges have lower capacity than absorption flasks, all cartridges were analysed by a third-party lab. Isokinetic gas sampling was performed on five occasions during the test period.

3. Results and discussion

3.1 Plant stability

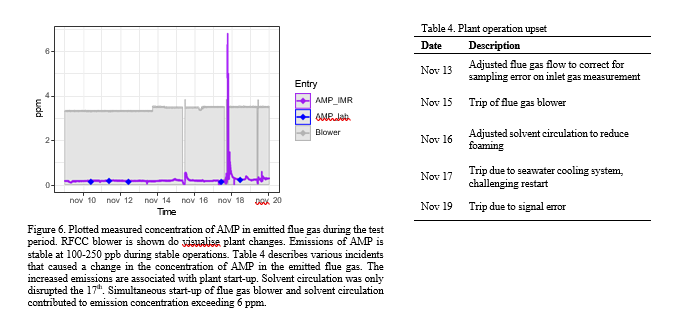

During the test period minor plant upsets occurred resulting in unstable plant conditions in the following hours (see Figure 6 and Table 3). The instruments capture the impact on process emissions prior to reaching a steady state. Shorter process upsets have negligible impact and emissions are relatively stable. However more complex situations or extended downtime can result in a significant elevation of emissions during a limited period. Accommodating for increased emissions during such eventualities should be described in the plant emission permit to ensure regulators and operators are aligned on acceptable limits that give operators the required flexibility to stabilise the plant in such scenarios.

3.2 Result evaluation

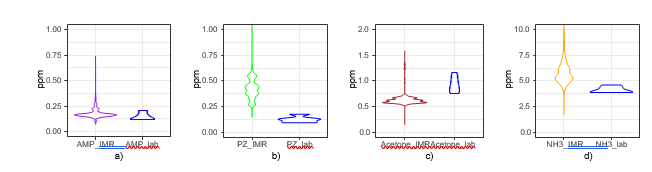

The incidents described above do not represent stable process conditions and are therefore removed from the dataset when comparing the performance of the IMR-MS instrument to established extractive sampling methods. Figure 7 shows violin plots of the cleaned online dataset and extractive lab sampling. Violin plots are similar to box plots but also visualize the distribution of measurements. Among the extractive samples, AMP results have the best agreement with the extractive samples (Figure 7a). As AMP was shown to be the primary emission component in previously

reported work [11], care was taken to implement enhancements to mitigate cross-sensitivity affecting AMP during calibration. The water content in the flue gas was the main component impacting the AMP signal, this was resolved by adding a linearization to the water signal in addition to a multiplicative enhancement with AMP. As seen in Figure 4 PZ has a fragmentation pattern that overlaps with the selected mass for AMP (see Table 2). The impact of this interaction is reduced with an enhancement (Table 2), as a result AMP is monitored with high accuracy.

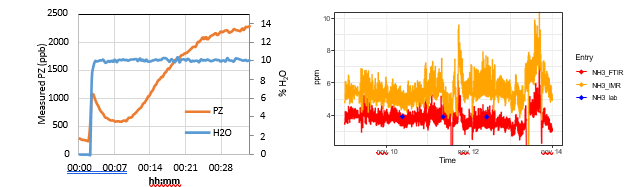

The calibration of PZ was challenging when using the available aqueous solutions and Hovacal setup. The component is sticky and adheres to the surfaces of the calibration equipment and lines. Therefore, achieving saturation of the Hovacal and inlet lines to the instrument were time consuming (30-60 minutes). A potential consequence is that a zero or span calibration was performed before the system had reached equilibrium, as is suggested in Figure 8, pointing to a bias in the span calibration. This could explain the instrument bias shown in Figure 7b.

Figure 7c shows poor agreement between the IMR-MS and the extractive samples for acetone. No clear explanation could be discerned by examining the calibration logs or setup. Further investigation is required.

Ammonia on the IMR-MS overestimates the concentration as can be seen in Figure 7d, however this is due to a calibration bias as is evident when comparing with FTIR results (see Figure 9). The instruments follow the same trends, and the bias should be resolved by improved the instrument calibration.

4. Conclusion

In this work we have successfully demonstrated the application of a new IMR-MS instrument for real-time monitoring and reporting of contaminants in the treated flue gas for an amine-based post-combustion carbon capture process. The instrument was installed in an industrial environment and measured the main emission components regulated in the emission permit of TCM.

The real-time monitoring and reporting of 2-methyl-2-aminopropan-1-ol (AMP) emissions was successfully conducted with a new IMR-MS instrument at TCM. The instrument accurately reported AMP in a range of 100-250 ppb. The instrument also reported PZ, acetone and ammonia but with lower accuracy. This was predominantly due to sub optimal calibration setups and procedures resulting in a systematic error. To mitigate some of the challenges experienced in this work dry calibration gasses should be used, preferably certified gas bottles. In addition, a more thorough screening of the flue gas contaminants and potential cross interactions of all contaminants should be assessed. This work demonstrates that commercial instruments capable of monitoring emissions in ppb range are available on the market. With application tailored calibration the instrument can be adapted to different flue gas sources and

capture solvents.

5. Acknowledgment

The authors gratefully acknowledge the staff of TCM DA, Gassnova, Equinor, Shell and TotalEnergies for their contribution and work at the TCM DA facility. The authors also gratefully acknowledge Gassnova, Equinor, Shell, and TotalEnergies as the owners of TCM DA for their financial support and contributions.

References

- IPCC, 2021: Summary for Policymakers. In: Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change [MassonDelmotte, Zhai VP, Pirani A, Connors SL, Péan C, Berger S, Caud N, Chen Y, Goldfarb L, Gomis MI, Huang M, Leitzell K, Lonnoy E, Matthews JBR, Maycock TK, Waterfield T, Yelekçi O, Yu R, and Zhou B (eds.)]. Cambridge University Press.

- a) Gjernes E, Pedersen S, Jain D, Åsen KI, Hvidsten OA, de Koeijer G, Faramarzi L, de Cazenove T, Documenting modes of operation with cost saving potential at the Technology Centre Mongstad, 14th Greenhouse Gas Control Technologies Conference Melbourne 21-26 October 2018 (GHGT-14), b) Faramarzi L, Thimsen D , Hume S, Maxon A, Watson G, Pedersen S , Gjernes E, Fostås BF, Lombardo G, Cents T, Morken AK, Shah MI, de Cazenove T, Hamborg ES, Energy Procedia, 114, 2017, 1128-1145, c) Morken A, Pedersen S, Kleppe ER, Wisthaler A, Vernstad K , Ullestad Ø , Flø NE, Faramarzi L, Hamborg ES, Energy Procedia, 114, 2017, 1245-1262, d) Benquet C, Knarvik A, Gjernes E, Hvidsten OA, Kleppe ER, Akhter S, First Process Results and Operational Experience with CESAR1 Solvent at TCM with High Capture Rates (ALIGN-CCUS Project), Proceedings of the 15th Greenhouse Gas Control Technologies Conference 15-18 March 2021.

- a) Johnsen K, Kleppe ER, Faramarzi L, Benquet C, Gjernes E, de Cazenove T , Morken AK, Flø N, Shah MI, Aronsson M, Ullestad Ø, CO2 product quality: assessment of the range and level of impurities in the CO2 product stream from MEA testing at the Technology Centre Mongstad (TCM), Proceedings of the 14th Greenhouse Gas Control Technologies Conference Melbourne 21-26 October 2018 (GHGT-14), b) Lombardo G, Shah MI, Fostås B, Hvidsten OA, Faramarzi L, de Cazenove T, Lepaumier H, Rogiers P, Results from testing of a Brownian diffusion filter for reducing the aerosol concentration in a residual fluidized catalytic cracker flue gas at the Technology Centre Mongstad, 14th Greenhouse Gas Control Technologies Conference Melbourne 21-26 October 2018 (GHGT-14).

- TCM emission permit, Permit Nr.: 2011.0257T, Plant Nr.: 1263.0105.01 – accessed 02.08.2022. https://www.norskeutslipp.no/WebHandlers/PDFDocumentHandler.ashx?documentID=577603&documentType=T&companyID=25735&aar=0&epslanguage=no

- a) Nielsen CJ, Herrmann H, Weller C, Chem. Soc. Rev., 41, 2012, 6684-6704, b) Låg M, Andreassen Å, Instanes C, Lindeman B, Health effects of amines and derivatives associated with CO2 capture, Norwegian Institute of Public Health, 2011, c) Gjernes E, Helgensen LI, Maree Y, Energy Procedia, 37, 2013, 735-742, d) de Koeijer G, Talstad VR, Nepstad S, Tønnesen D, Falk-Pedersen O, Maree Y, Nielsen CJ, 2013, 18, 200-207, e) Tan W, Zhu L, Mikoviny T, Nielsen CJ, Wisthaler A, D’Anna B, Antonsen S, Stenstrøm Y, Farren NJ, Hamilton JF, Boustead GA, Brennan AD, Ingham T, Heard DE. J. Phys. Chem. A, 125, 2021, 411-422, f) Tan W, Zhu L, Mikoviny T, Nielsen CJ, Tang Y, Wisthaler A, Eichler P, Müller M, D’Anna B, Farren NJ, Hamilton JF, Petterson JBC, Halliquist M, Antonsen S, Stenstrøm Y, J. Phys. Chem. A, 125, 2021, 7502-7519.

- Tønnesen D, CO2-capture at Klemetsrud. Modelling of nitros- and nitramines, Norwegian Institute for Air Research, NILU report 11/2018. https://hss.miljodirektoratet.no/api/1/publisert/hoering/vedlegg/16832, accessed 20.07.20

- a) Languille B, Drageset A, Mikoviny T, Zardin E, Benquet C, Ullestad Ø, Aronson M, Kleppe ER, Wisthaler A, Best practices for the measurement of 2-amino-2-methyl-1-propanol, piperazine and their degradation products in amine plant emissions, 15th Greenhouse Gas Control Technologies Conference Abu Dhabi 15-18 March 2021 (GHGT-15), b) Languille B, Drageset A, Mikoviny T, Zardin E, Benquet C, Ullestad Ø, Aronsson M, Kleppe ER, Wisthaler A, Atmospheric emissions of amino-methyl-propanol, piperazine and their degradation products during the 2019-20 ALIGN-CCUS campaign at the Technology Centre Mongstad, 15th Greenhouse Gas Control Technologies Conference Abu Dhabi 15-18 March 2021 (GHGT-15).

- Akinpelumi K, Saha C, Rochelle GT, Piperazine aerosol mitigation for post-combustion carbon capture, International Journal of Greenhouse Gas Control, 2019, 91, 102845.

- Hume, SA McMaster, Drageset A, Shah, MI, Kleppe ER, Results from CESAR1 testing at the CO2 Technology Centre Mongstad. Verification of Residual Fluid Catalytic Cracker (RFCC) baseline results, 16th Greenhouse Gas Control Technologies Conference Lausanne 23-27 October 2022 (GHGT-16).

- a) de Cazenove T, Bouma RHB, Goetheer ELV, van Os PJ, Hamborg ES, Aerosol Measurement Technique: Demonstration at CO2 Technology Centre Mongstad, Energy Procedia, 2016, 86, 160-170, b) Lombardo G, Fostås BF, Shah MI, Morken AK, Hvidsten OA, Mertens J, Hamborg ES, Results from aerosol measurement in amine plant treating gas turbine and Residue Fluidized Catalytic Cracker flue gases at the CO2 Technology Centre Mongstad, 13th Greenhouse Gas Control Technologies Conference Lausanne 14-18 November 2016 (GHGT-13).

- Lodge JrJP, Methods of Air sampling and Analysis, Third edition, CRC Press, 1989.

- a) Sauer C, Lorén A, Schefer A, Carlsson P-A, On-Line Composition Analysis of Complex Hydrocarbon Streams by Time-Resolved Fourier Transform Infrared Spectroscopy and Ion−Molecule Reaction Mass Spectrometry, Analytical Chemistry 2021, 93, 13187-13195, b) Wang Y, Han H, Shen S, Li J, Wang H, Chu Y, Control of solvent use in medical devices by proton transfer reaction mass spectrometry and ion molecule reaction mass spectrometry, Journal of Pharmaceutical and Biomedical Analysis, 2009, 50, 252-256, c) Dearth MA, Evaluation of a Commercial Mass Spectrometer for Its Potential To Measure Auto Exhaust Constituents in Real Time, Industrial & Engineering Chemistry Research, 1999, 38, 2203-2209.

Atmospheric emissions of amino- methyl-propanol, piperazine and their degradation products during the 2019–20 ALIGN-CCUS campaign at the Technology Centre Mongstad (2021)

Baptiste Languillea, Audun Dragesetb, Tomas Mikovinya, Erika Zardina, Christophe Benquetb,c, Øyvind Ullestadb,d, Magnus Aronsonb,d, Eirik Romslo Kleppeb,d, Armin Wisthalera*

aUniversity of Oslo, Department of Chemistry, P.O. Box 1033 Blindern, 0351 Oslo, Norway bTechnology Centre Mongstad (TCM), 5954 Mongstad, Norway cTotal E&P Norge, Finnestadveien 44, Dusavik, 4029 Stavanger, Norway dEquinor ASA, PO Box 8500, 4035 Stavanger, Norway *Corresponding author

Abstract

In the frame of the 2019-20 ALIGN-CCUS campaign, the amine plant at the Technology Centre Mongstad (TCM) was operated with the CESAR 1 solvent, i.e. an aqueous solution of 2-amino-2-methylpropan-1-ol (AMP) and piperazine (PZ), for removing carbon dioxide from the flue gas of Equinor’s combined cycle gas turbine plant. An online Proton-Transfer-Reaction Time-of- Flight Mass Spectrometer (PTR-TOF-MS) was used for quantifying atmospheric emissions of AMP and PZ, as well as emissions of amine degradation products and solvent impurities. Mean and median AMP levels emitted to the atmosphere over an operational period of 13 weeks were 562 and 377 ppb, respectively. PZ emissions to the atmosphere were much lower, with mean and median levels being 6.0 and 0.4 ppb, respectively. Three small carbonyl species (formaldehyde, acetaldehyde, acetone) were emitted at levels of tens to hundreds of ppb. Nitrogen-containing degradation products and impurities of solvent amines with mean emission levels >1 ppb included the following compounds: monomethylamine (MMA), formamide (FA), morpholine (MOR), 4,4- dimethyloxazolidine (DMO), 2-methyl-2-(methylamino)propan-1-ol (MeAMP), 4-acetylmorpholine (AMOR) and a compound with a molecular sum formula of C8H14N2, which we tentatively assigned to an alkylated imidazole or pyrazole. Low (<5 ppm) emissions of AMP were associated with a low flue gas temperature (<38 °C) and large temperature gradient between the two water wash sections.

1. Introduction

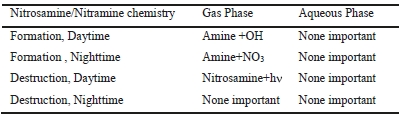

Amine-based post-combustion carbon capture (PCCC) is the technologically most mature solution for removing carbon dioxide (CO2) from a flue gas stream. The reduction in CO2 emissions comes, however, at the expense of amine emissions to the atmosphere. Atmospheric oxidation processes may partially transform the emitted amines into nitrosamines and nitramines [1], which are substances with known carcinogenic or potential carcinogenic properties. Since it is not possible to monitor and surveil nitrosamines and nitramines at ambient sub-ng/m³ levels, exposure to nitrosamines and nitramines is usually calculated taking into account dispersion and atmospheric processing of emitted amines. A key input parameter to such calculations is the emission rate of solvent amines and of smaller amines formed during solvent degradation. Amine emission data are thus of pivotal importance for ensuring an environmentally safe operation of an amine-based PCCC plant. A recent review by Scottish Environment Protection Agency [2] concludes that there is limited open source data available on amine emissions to the atmosphere and that most available data is based on capture solvents such as monoethanolamine (MEA) that are not necessarily representative of the mix of solvents used in state-of-the-art PCCC plants.

The Technology Centre Mongstad (TCM) (www.tcmda.com) in Norway is one of the world’s leading facilities for testing and improving CO2 capture technologies. TCM’s tasks also include the assessment of amine emissions to the atmosphere and the development of emission reduction strategies. Only few results from the emission measurements have, however, hitherto been disclosed. This is because detailed emission data would reveal the chemical composition of the solvent, which is, in most cases, confidential business information. Therefore, only MEA emission data are currently available in the open literature [3, 4].

ALIGN-CCUS (Accelerating Low CarboN Industrial Growth through Carbon Capture Utilisation and Storage) is a project financed through the first ERA-NET Co-fund ACT program funded by nine European countries and the European Union Horizon 2020 program. The ALIGN consortium includes 31 partners from industry, research and academia and has considerable involvement of industrial companies and an enterprise organization. The ALIGN- CCUS project aims at accelerating the transition of current industry and power sectors into a future of continued economic activity and low-carbon emissions, in which carbon capture, utilization and storage (CCUS) plays an essential role. For optimizing and reducing costs of PCCC, the ALIGN consortium has implemented test programs at four different pilot plants and testing facilities including TCM, the SINTEF pilot rig at Tiller/Trondheim in Norway, RWE’s Coal Innovation Centre at Niederaussem in Germany, and the Pilot-scale Advanced CO2 Capture Technology (PACT) facilities in Sheffield in the United Kingdom. TCM’s contribution to the ALIGN-CCUS project is aimed at bridging knowledge gaps as well as reducing HSE, technical and financial risks of technology upscaling.

In the 2019-20 ALIGN-CCUS campaign at TCM, flue gas from Equinor’s combined cycle gas turbine (CCGT) plant in Mongstad was treated with the aqueous 2-amino-2-methylpropan-1-ol (AMP) / piperazine (PZ) (CESAR 1) solvent. The CESAR 1 solvent was selected due to its lower energy consumption and higher stability as compared to MEA. Among the topics of the study were emission control and monitoring as well as solvent consumption. The main goal of the campaign was to demonstrate that this advanced amine solvent can be used at a large scale and with a real flue gas.

Results from the ALIGN-CCUS project are in the open domain, and we are herein reporting, for the first time, atmospheric emission data of AMP, PZ and their degradation products.

2. Method

The ALIGN-CCUS 2019-2020 campaign was carried out at TCM from September 12, 2019 to January 10, 2020. Flue gas from Equinor’s CCGT plant in Mongstad was treated in TCM’s amine plant operating with the CESAR 1 solvent. The chemical-analytical set-up to measure atmospheric emissions of amines, amine impurities and amine degradation products is described in detail in a companion paper [5]. Herein, we only use the data collected with an online Proton-Transfer-Reaction Time-of-Flight Mass Spectrometer (PTR-TOF-MS) [3]. The calibration of AMP and PZ is also described in the companion paper. Formaldehyde, acetaldehyde and acetone as well as acetonitrile were calibrated using a dynamically diluted calibration gas standard (Apel-Riemer Environmental, Inc., Miami, FL, USA). All other compounds are reported as acetone-equivalents, i.e. the acetone response factor was used for signal quantification. Reported volume mixing ratios have an accuracy of ±10% for calibrated compounds, and ±50% for compounds reported as acetone-equivalents.

3. Results and discussion

3.1 Atmospheric emissions of AMP and PZ

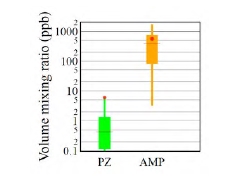

Figure 1 shows the distribution of AMP and PZ volume mixing ratios, respectively, as measured during the 2019- 2020 ALIGN-CCUS campaign at TCM. Mean and median AMP levels emitted were 562 and 377 ppb, respectively. PZ emissions were much lower, with mean and median levels being 6.0 and 0.4 ppb, respectively. The mean value is significantly higher than the median value because of sporadic PZ bursts. No experimental data are available in the open literature to compare our data with. Kolderup et al. [6] carried out modeling simulations and estimated total AMP and PZ emissions in the 0.55 – 30 ppm range. The AMP levels observed in this study were similar to MEA levels found in previous work at TCM [7, 4, 8]. Notably, AMP emissions were typically three orders of magnitude higher than PZ emissions. Khakharia et al. [9] reported an AMP-to-PZ emission ratio of 26, while Mertens et al. [10] found two orders of magnitude higher AMP emissions as compared to PZ. This discrepancy cannot be explained by the AMP-to-PZ-ratio in the solvents (3 M AMP and 1.8 M PZ in the Mertens et al. study [10]; 3.6 M AMP and 0.9 M PZ in the Khakharia et al. study [9]; 3 M kg-1 AMP and 1.5 M kg-1 PZ in the CESAR 1 solvent). The low PZ emission levels observed during the ALIGN-CCUS campaign can be explained by a low entrainment rate of PZ into the gas phase and/or more efficient scrubbing of PZ in the water wash sections.

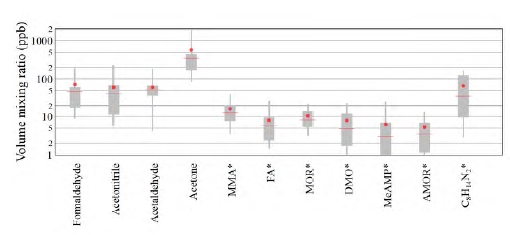

3.2 Atmospheric emissions of amine degradation products and impurities

10 amine degradation products and 1 solvent impurity were emitted to the atmosphere with a mean and median volume mixing ratio above 1 ppb during the ALIGN-CCUS 2019-2020 campaign (Figure 2). Three small carbonyl species (formaldehyde, acetaldehyde, acetone) were emitted at levels of tens to hundreds of ppb, with acetone reaching the highest levels. It was observed previously [12, 13] that acetone is a major decomposition product of an aqueous AMP/PZ blend. Seven of the remaining species that were emitted to the atmosphere included one nitrogen atom: monomethylamine (MMA), formamide (FA), morpholine (MOR), 4,4-dimethyloxazolidine (DMO), 2-methyl-2- (methylamino)propan-1-ol (MeAMP), and 4-acetylmorpholine (AMOR). The remaining compound has a molecular sum formula of C8H14N2, which we tentatively assign to an alkylated imidazole or pyrazole. Notably, MMA was emitted at a mean level of almost 20 ppb. Wang [12] expected MMA to be formed from AMP degradation but did not detect it. Wang [12] also observed the formation of formamide when exposing AMP to UV radiation. MeAMP is a common impurity of AMP and DMO has been observed as a decomposition compound in the liquid phase [12]. But so far, they have not been reported as being released to the atmosphere. MOR, AMOR and C8H14N2 have not been reported previously. It is also noteworthy that 1-nitrosopiperazine was detected in the emitted flue gas. A tentative quantification puts emission levels well below 1 ppb, but more calibration work is needed for quantifying nitrosamines.

Fig. 1. Distribution of volume mixing ratios of PZ and AMP emitted to the atmosphere when flue gas from Equinor’s CCGT plant in Mongstad was scrubbed of CO2 in TCM’s amine plant operating with the CESAR 1 solvent. Boxes represent 25th and 75th percentiles, the horizontal line is the median, the dot is the mean, and whiskers represent 5th and 95th percentiles.

Fig. 2. Distribution of the 10 amine degradation products and 1 solvent impurity (MeAMP) that were emitted to the atmosphere with a mean level. > 1 ppb. Boxes represent 25th and 75th percentiles, the horizontal line is the median, the dot is the mean, and whiskers represent 5th and 95th percentiles. Compounds marked with an asterisk (*) are reported as in acetone-equivalent mixing ratios (see text).

3.3 Impact of the operational parameters of the plant

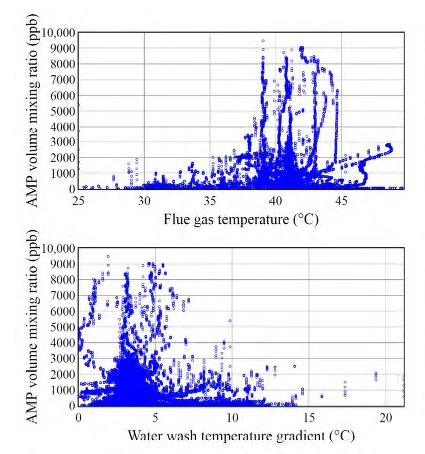

The operating parameters of the amine plant obviously influence the level of emissions. Mertens et al. [10] found that emissions depend upon the flue gas temperature and the temperature gradient over the water wash (WW) section. Our initial analysis thus focused on the effect of these two parameters on atmospheric emissions. Figure 3 (upper panel) shows that high (>5 ppm) AMP emissions were associated with high (>38 °C) flue gas temperatures. Figure 3 (lower panel) on the other hand shows that high AMP emissions only occurred when the temperature gradient between the two WW sections was low. Emissions of PZ and degradation products exhibited similar trends. More details will be disclosed in a forthcoming paper.

Our findings are thus in agreement with the observations by Mertens et al. [10], and this information may be used to mitigate emissions from amine plants. Previous work [9, 11] has, however, also shown that other parameters such as solvent temperature, pH and CO2 content significantly impact atmospheric emissions. The effect of additional parameters will be investigated in future work.

Finally, we would like to point out that the results shown here were obtained when the amine plant was operated with flue gas from the CCGT plant. This flue gas has a low acidic content, which prevents the formation of aerosol particles (“mist”) in the absorber column. Currently ongoing studies indicate that emission profile changes significantly when the amine plant runs on the other flue gas available at TCM, which is from the Residue Fluid Catalytic Cracker (RFCC). The results from these ongoing studies will be presented in future work.

Fig. 3. Scatter plots of AMP emissions versus flue gas temperature (upper panel) and AMP emissions versus the temperature gradient over the water wash sections (lower panel). Data associated with flue gas temperatures below 25 °C were not included in the analysis. Such low temperatures only occur during the plant warm-up and not during regular plant operation.

Conclusions

We herein report, for the first time, the levels of AMP and PZ as well as of their degradation products that are emitted into the atmosphere from a PCCC plant, which was operated on the CESAR 1 solvent. Significant emissions of AMP and of two small reactive carbonyls (formaldehyde, acetaldehyde) will need to be considered in any atmospheric impact assessment study, while minor emissions of other degradation products (in particular of 1- nitrosopiperazine) warrant further investigations. We also characterized the impact of specific plant parameters on emissions and found that high (>5 ppm) AMP emissions were associated with a high flue gas temperature (>38 °C) and small temperature gradient between the two water wash sections. A more in-depth analysis of the collected data will allow us to give recommendations for mitigating emissions from amine-based PCCC plants operating on the advanced CESAR 1 solvent.

Acknowledgements

ACT ALIGN-CCUS Project No 271501. This project has received funding from RVO (NL), FZJ/PtJ (DE), Gassnova (NO), UEFISCDI (RO), BEIS (UK) and is co-funded by the European Commission under the Horizon 2020 programme ACT, Grant Agreement No. 691712 (www.alignccus.eu).

The authors gratefully acknowledge the staff of TCM DA, Gassnova, Equinor, Shell and TotalEnergies for their contribution and work at the TCM DA facility. The authors also gratefully acknowledge Gassnova, Equinor, Shell, and Total as the owners of TCM DA for their financial support and contributions.

References

- Nielsen CJ, Herrmann H, and Weller C. Atmospheric chemistry and environmental impact of the use of amines in carbon capture and storage (CCS). Chem. Soc. Rev., 41 :6684–6704, 2012.

- SEPA Scottish Environment Protection Agency. Review of amine emissions from carbon capture systems. Stirling, UK, pages 1–86, 2015.

- Zhu L, Schade G, and Nielsen CJ. Real-time monitoring of emissions from monoethanolamine-based industrial scale carbon capture facilities. Environmental science & technology, 47, 11 2013.

- Morken A, Pedersen S, Kleppe ER, Wisthaler A, Vernstad K, Ullestad Ø, Flø NE, Faramarzi L, and Hamborg ES. Degradation and emission results of amine plant operations from MEA testing at the CO2 Technology Centre Mongstad. Energy Procedia, 114:1245–1262, 07 2017.

- Languille B, Drageset A, Mikoviny T, Zardin E, Benquet C, Ullestad Ø, Aronson M, Kleppe ER, Wisthaler A. Best practices for the measurement of 2-amino-2-methyl-1-propanol, piperazine and their degradation products in amine plant emissions, 15th International Conference on Greenhouse Gas Control Technologies, GHGT-15, 15th 18th March 2021 Abu Dhabi, UAE

- Kolderup H, Silva E, Mejdell T, Tobiesen A, Haugen G, Hoff KA, Josefsen K, Strøm T, Furuseth O, Hanssen KF, Wirsching H, Myhrvold T, and Johnsen K. Emission reducing technologies amine. SINTEF Materials and Chemistry, pages 1 – 123, 2011.

- Morken A, Nenseter B, Pedersen S, Chhaganlal M, Feste JK, Tyborgnes RB, Ullestad Ø, Ulvatn H, Zhu L, Mikoviny T, Wisthaler A, Cents A, Bade O, Knudsen J, Koeijer G, Pedersen OF, and Hamborg ES. Emission results of amine plant operations from MEA testing at the CO2 Technology Centre Mongstad. Energy Procedia, 63: 6023–6038, 12 2014.

- Zhu L, Mikoviny T, Morken AK, Tan W, and Wisthaler A. A compact and easy-to-use mass spectrometer for online monitoring of amines in the flue gas of a post-combustion carbon capture plant. International Journal of Greenhouse Gas Control, 78:349 – 353, 2018.

- Khakharia P, Brachert L, Mertens J, Anderlohr C, Huizinga A, Fernandez ES, Schallert B, Schaber K, Vlugt TJH and Goetheer E. Understanding aerosol based emissions in a post combustion CO2 capture process: Parameter testing and mechanisms. International Journal of Greenhouse Gas Control, 34:63 – 74, 2015.

- Mertens J, Knudsen J, Thielens ML, and Andersen J. On-line monitoring and controlling emissions in amine post combustion carbon capture: A field test. International Journal of Greenhouse Gas Control, 6:2–11, 01 2012.

- Fulk SM and Rochelle GT. Quantification of gas and aerosol-phase piperazine emissions by FTIR under variable bench-scale absorber conditions. Energy Procedia, 63:871 – 883, 2014. 12th International Conference on Greenhouse Gas Control Technologies, GHGT-12.

- Wang T. Degradation of Aqueous 2-Amino-2-methyl-1-propanol for Carbon Dioxide Capture. PhD thesis, 2013.

- Wang T and Jens KJ. Oxidative degradation of aqueous PZ solution and AMP/PZ blends for post-combustion carbon dioxide capture. International Journal of Greenhouse Gas Control, 24:98 – 105, 2014.

Best practices for the measurement of 2-amino-2- methyl-1-propanol, piperazine and their degradation products in amine plant emissions (2021)

Baptiste Languillea, Audun Dragesetb, Tomas Mikovinya, Erika Zardina, Christophe Benquetb, Øyvind Ullestadb, Magnus Aronsonb, Eirik Romslo Kleppeb, Armin Wisthalera*

aUniversity of Oslo, Department of Chemistry, P.O. Box 1033 Blindern, 0351 Oslo, Norway bTechnology Centre Mongstad (TCM), 5954 Mongstad, Norway cTotal E&P Norge, Finnestadveien 44, Dusavik, 4029 Stavanger, Norway dEquinor ASA, PO Box 8500, 4035 Stavanger, Norway *Corresponding author

Abstract

We herein present the chemical-analytical setup used to measure atmospheric emissions of amines and amine degradation products from an amine-based post-combustion carbon capture plant. The emission measurements were carried out at the Technology Centre Mongstad (TCM) in Norway, in the frame of the ALIGN-CCUS campaign from September 2019 to January 2020, when the amine plant was operated with the CESAR 1 solvent. This advanced solvent is an aqueous solution of 2-amino-2-methyl-1-propanol (AMP) and piperazine (PZ). Four chemical-analytical techniques were deployed for characterizing emission of AMP, PZ and their degradation products: online Fourier Transform Infrared (FTIR) Spectroscopy, online Proton-Transfer-Reaction Time-of-Flight Mass Spectrometry (PTR-TOF-MS), online Proton-Transfer-Reaction Quadrupole Mass Spectrometry (PTR-QMS), as well as manual impinger sampling followed by offline Ion Chromatography Mass Spectrometry (IC-MS) analysis. AMP was detected by all four methods, with the results being in reasonably good agreement. PZ was detected by PTR-TOF-MS, PTR-QMS and IC-MS, but because of the low emission levels (single-digit ppb) the latter two methods suffered from a positive bias (due to an interfering compound) and a large measurement uncertainty, respectively. 17 amine degradation products were only detected by the PTR- ToF-MS analyzer. We present exemplary results from the emission measurements carried out during the ALIGN-CCUS 2019- 2020 campaign and share some of the lessons learned from this exercise.

![]() 1. Introduction

1. Introduction

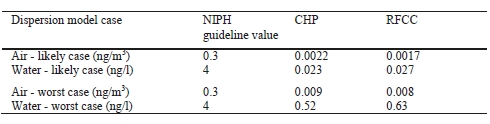

Amine-based post-combustion carbon capture (PCCC) is the technologically most mature solution for removing carbon dioxide (CO2) from a flue gas stream. The reduction in CO2 emissions does, however, come at the expense of amine emissions to the atmosphere [1]. Atmospheric oxidation processes may partially transform the emitted amines into nitrosamines and nitramines [2], which are substances with known carcinogenic or potential carcinogenic properties. Based on a conservative risk analysis, inhalation exposure to the sum of PCCC-derived nitrosamines and nitramines should be kept below an annual average concentration of only 0.3 ng m-3 [3] for the general public. Since it is not possible to monitor such low concentrations in the atmosphere, exposure to nitrosamines and nitramines is calculated taking into account emission rates of amines, as well as the dispersion and atmospheric processing of emitted amines. Amine emission rates need to be measured, but their low concentrations (typically 0.1-10 ppm) and the high humidity levels in the treated flue gas make this a challenging analytical effort.

The Technology Centre Mongstad (TCM) (www.tcmda.com) in Norway is one of the world’s leading facilities for testing and improving CO2 capture technologies. TCM’s tasks also include the validation and optimization of emission sampling and measurement techniques. TCM has put considerable efforts into the characterization of atmospheric emissions and nowadays routinely monitors amines in the absorber effluent stream using a variety of analytical methods [4]. These include online Fourier Transform Infrared (FTIR) Spectroscopy, online Proton-Transfer-Reaction Time-of-Flight Mass Spectrometry (PTR-TOF-MS) [5], online Proton-Transfer-Reaction Quadrupole Mass Spectrometry (PTR-QMS) [6], as well as manual impinger sampling followed by offline Ion Chromatography Mass Spectrometry (IC-MS) analysis [4]. While amine emission data are routinely reported to the authorities, only few results have hitherto been publicly disclosed because the solvent composition is, in most cases, confidential.

ALIGN-CCUS (Accelerating Low CarboN Industrial Growth through Carbon Capture Utilisation and Storage) is a project financed through the first ERA-NET Co-fund ACT program funded by nine European countries and the European Union Horizon 2020 program. The ALIGN consortium includes 31 partners from industry, research and academia and has considerable involvement of industrial companies and an enterprise organization. The ALIGN- CCUS project aims at accelerating the transition of current industry and power sectors into a future of continued economic activity and low-carbon emissions, in which carbon capture, utilization and storage (CCUS) plays an essential role. For optimizing and reducing costs of PCCC, the ALIGN consortium has implemented test programs at four different pilot plants and testing facilities including TCM, the SINTEF pilot rig at Tiller/Trondheim in Norway, RWE’s Coal Innovation Centre at Niederaussem in Germany, and the Pilot-scale Advanced CO2 Capture Technology (PACT) facilities in Sheffield in the United Kingdom. TCM’s contribution to the ALIGN-CCUS project is aimed at bridging knowledge gaps as well as reducing HSE, technical and financial risks of technology upscaling.

In the ALIGN-CCUS 2019-2020 campaign at TCM, flue gas from Equinor’s combined cycle gas turbine (CCGT) plant in Mongstad was treated with the aqueous 2-amino-2-methyl-1-propanol (AMP) / piperazine (PZ) (CESAR 1) aqueous solvent. The CESAR 1 solvent was selected due to its lower energy consumption and higher stability as compared to monoethanolamine (MEA). Its promising characteristics have made CESAR 1 the new benchmark IEAGHG amine solvent. Emission control and monitoring as well as solvent consumption were among the study topics of the ALIGN-CCUS 2019-2020 campaign. The main goal of the campaign was to demonstrate that this advanced amine solvent can be used at a large scale and with a real flue gas. Results from the ALIGN-CCUS project are in the open domain, thus offering the opportunity to show, for the first time, qualitative and quantitative results on the measurement of AMP and PZ in the absorber effluent. Emission data will be presented in a companion paper.

In this work, we will present the chemical-analytical methods used for carrying out the emission measurements during the ALIGN-CCUS 2019-2020 campaign and present some of the results along with the lessons learned from this exercise.

![]() 2. Methods

2. Methods

2.1 Overview of the campaign and overall system description

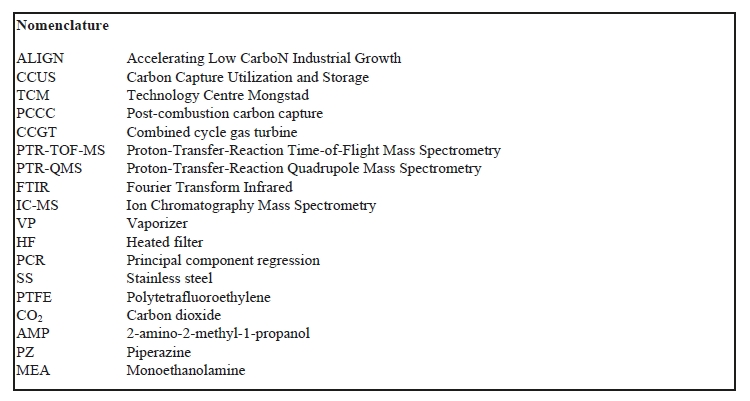

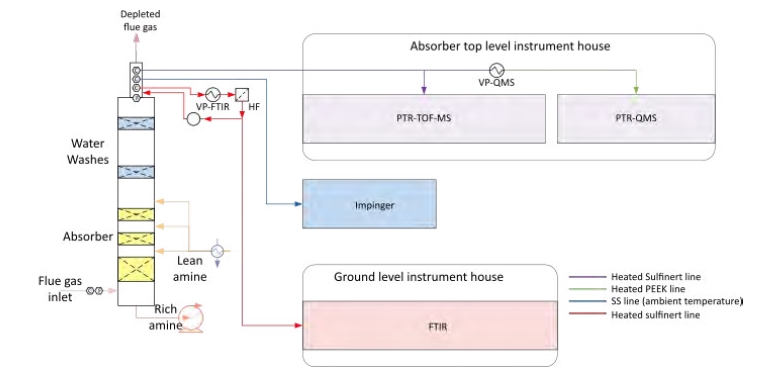

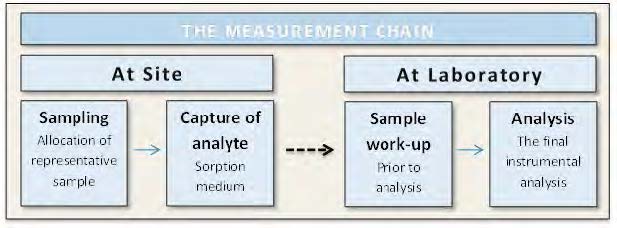

The ALIGN-CCUS campaign at TCM was conducted from September 12th 2019 to January 10th 2020. As already stated above, flue gas from a CCGT plant was treated with the CESAR 1 solvent. Figure 1 is a sketch of the analytical set-up used for emission monitoring. Table 1 gives an overview of the analytical methods used for emission monitoring, their time of deployment, the measurement frequency and the compounds measured.

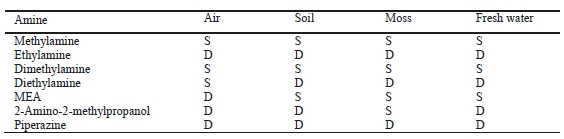

Table 1. Overview of the analytical methods used for emission monitoring, their time of deployment, the measurement frequency and the compounds measured.

Fig. 1. Process flow diagram of emission sampling of absorber outlet. (VP: vaporizer).

2.2 Proton-Transfer-Reaction Mass Spectrometry (PTR-MS)

PTR-MS is a well-established technique for monitoring organic trace gases online (i.e., without sample pre- treatment), at a typical measurement frequency of 1 Hz and down to ppt levels [7]. In PTR-MS, the gas to be analyzed is introduced into a low-pressure reaction cell wherein organic molecules are softly ionized via gas-phase proton transfer reactions with H3O+ ions [8]. The protonated analyte molecules are detected in a quadrupole mass spectrometer (QMS) or a time-of-flight mass spectrometer (TOF-MS). [5] have described the use of PTR-MS for monitoring amines in the treated flue gas emanating from an amine-based PCCC plant. For the work presented herein, we used two different PTR-MS instruments, a PTR-TOF-MS analyzer (model PTR-TOF 8000; Ionicon Analytik, Innsbruck, Austria) and a PTR-QMS instrument (model QMS 300; Ionicon Analytik, Innsbruck, Austria). The latter is a cheaper and easier to use instrument version, which was conceived for industrial monitoring purposes. Both instruments were placed in an analyzer house on top of the absorption tower, and connected to the stack via a ~10 m long heated (120 °C) sampling line made of SilcoNert2000®/Sulfinert. The subsampling line of the PTR-QMS instrument included a vaporizer (VP-QMS) for evaporating potential mist particles. The operating parameters of both PTR-MS instruments were as follow: drift tube pressure 2 mbar, drift tube temperature 120 °C, drift tube voltage 500 V. The resulting reduced electric field strength (E/N) was ~150 Td (1 Td = 10-17 V.cm2).

Both PTR-MS instruments were calibrated for AMP and PZ using a HovaCAL® calibration gas generator (model

312-MF; IAS GmbH, Oberursel, Germany). A quantitative aqueous amine solution (AMP, PZ) was prepared by TCM’s analytical laboratory. This solution was evaporated at 180 °C in the HovaPOR evaporator (IAS GmbH, Oberursel, Germany) under a pure nitrogen atmosphere. By increasing the calibration solution flow into the evaporator, the humidity increases in the resulting calibration gas. This allowed us to study the response of the two PTR-MS instruments at different humidity levels.

2.3 Fourier Transform Infrared (FTIR) Spectroscopy

The FTIR instrument (Analect 5000; Schneider Electric) was located in the analyzer house at the bottom of the absorption tower. It was connected to the stack via a 100 m long sampling line made of SilcoNert2000®/Sulfinert. The flue gas was extracted from the stack at a fixed flow rate using a fast flow loop system mimicking isokinetic conditions [9]. The fast flow loop system included a vaporizer (VP-FTIR) for evaporating potential mist particles and a heated filter (HF). The temperatures of these units were adjusted to minimize the thermal degradation of analytes. The FTIR instrument was calibrated using the same HovaCAL® calibration gas generator as described above. Principal component regression (PCR) models were used for extracting CO2, H2O, NO, NO2, SO2, NH3, acetaldehyde, formaldehyde, AMP and PZ from the FTIR spectra.

2.4 Impinger sampling followed by Ion Chromatography Mass Spectrometry (IC-MS) analysis

Samples were extracted isokinetically and collected in a standard impinger sampling train including a condensation flask, a filter flask and three absorption flasks. Typical sampling times were 1-2 hours. The samples were analyzed in TCM’s laboratory using a Dionex Integrion HPIC System (model ICS-5000, Thermo Fisher Scientific) which included an IonPac CS19 column and an IonPac CG19 guard column.

![]() 3. Results and Discussion

3. Results and Discussion

3.1 Measurement of AMP emissions and encountered difficulties

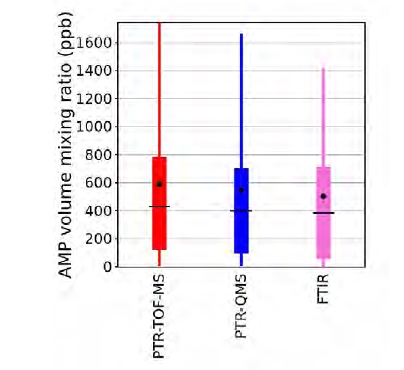

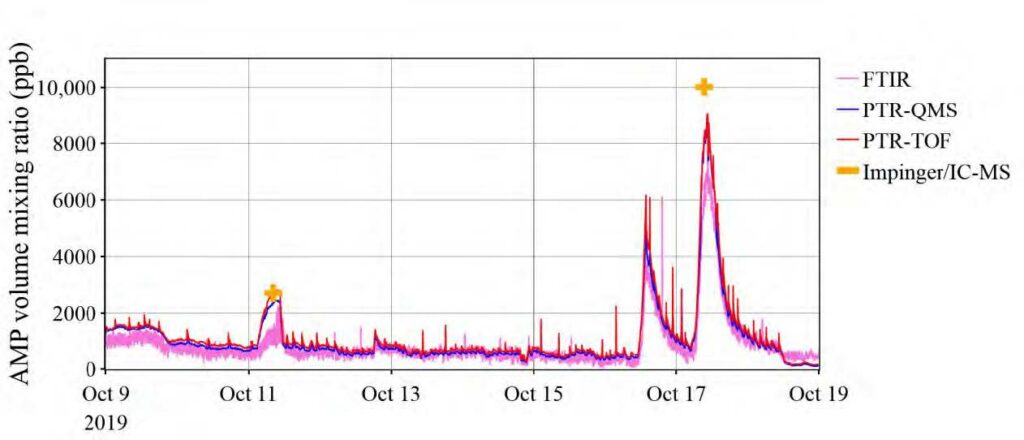

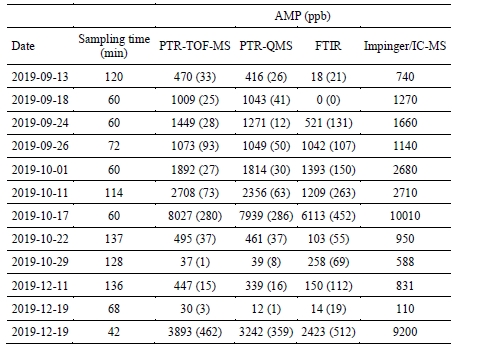

The only compound detected by all four measurement techniques was AMP. The results obtained with the four methods were in good agreement. As shown in Figure 2, the distribution of the measured AMP volume mixing ratios was very similar, with the PTR-TOF-MS, the PTR-QMS and the FTIR instrument measuring median AMP levels of 433, 400 and 388 ppb, respectively. Mean measured AMP levels were 592, 549 and 503 ppb, respectively. Figure 3 shows an exemplary time series of AMP as recorded over a period of ten days. Two impinger samples were collected during this period. The measurements are again in good agreement, the only major discrepancy being the systematically lower levels measured by the FTIR instrument during periods with enhanced emissions. Table 2 shows a systematic comparison for all data collected during twelve impinger sampling periods, with sample collection times ranging from 42 to 136 minutes. The overall agreement was good, even though in some case large discrepancies were observed. It is not clear why the level of agreement varied between the samples. Future work is needed for addressing this issue.

Fig. 2. Distribution of AMP volume mixing ratios as measured in the emitted flue gas by the PTR-TOF-MS, PTR-QMS and FTIR instruments, respectively, over the duration of the whole 2019-2020 ALIGN-CCUS campaign. Boxes represent 25th and 75th percentiles, the black line is the median, and the black dot is the mean. Whiskers represent 5th and 95th percentiles.

Fig. 3. Exemplary time series of AMP volume mixing ratios as measured in the emitted flue gas by the PTR-TOF-MS, PTR-QMS and FTIR instruments, respectively, in the period from October 9 to October 19, 2019. Also included are the two discrete measurement points obtained via impinger sampling followed by IC-MS analysis.

Table 2. AMP mixing ratios as measured by all four measurement techniques during the impinger sampling periods. Standard deviations are given in brackets.

A number of problems and difficulties were observed for all of the measurement methods used during the ALIGN- CCUS campaign. A forthcoming paper will address these issues in more detail and only a brief outline is given here.

The FTIR analyzer was sampling through a 100 m long sampling line. Long sampling lines are known to require long conditioning times for amines, meaning that peak levels were dampened and thus underestimated. In addition, we found that a stainless steel (SS) line originally connected to the FTIR instrument was corroded. The SS line was replaced with a sampling line made of polytetrafluoroethylene (PTFE) during the campaign. AMP degrades when in contact with a hot SS surface. It was thus important to reduce the temperature of the vaporizer (see Figure 1) to a level at which no AMP decomposition is observed. Finally, it should be noted that the AMP concentrations in the treated flue gas were close to the detection limit of the FTIR instrument, which made the measurements with this instrument less accurate.

The response of PTR-MS instrument to amines usually does not depend on the humidity of the sample matrix. This was not the case for AMP. The response of the PTR-QMS and the PTR-TOF-MS instruments varied by a factor of 5 between dry and humid conditions. For obtaining accurate results, it was essential to calibrate both instruments over the full range of humidity levels observed in the flue gas stack. Also, the reduction, processing and analysis of the PTR-TOF-MS data was highly complex and time-consuming and required a full time engagement of an expert scientist.

Impinger sampling followed by ICMS analysis is time consuming and laborious. Only 12 samples were thus collected and analysed over a period of the whole campaign. In addition, the measurement uncertainty was high at low ppb levels. Only AMP (typically >100 ppb) was thus quantitatively reported from the IC-MS analysis.

Finally, it should be noted, that during the ALIGN-CCUS campaign no mist was observed in the treated flue gas. Measurement problems that occurred in the presence of mist will be presented in a separate study.

3.2 Measurement of PZ

PZ was only present at low ppb levels in the treated flue gas, meaning that only the PTR-TOF-MS instrument was able to quantitatively detect it. PZ also exhibited a humidity-dependent response. It was thus necessary to carry out a humidity-dependent calibration of the PTR-TOF-MS instrument. The PTR-QMS instrument also detected an ion signal at m/z 87, which corresponds to protonated PZ. An intercomparison with the PTR-TOF-MS data revealed that a second peak at m/z 87 (which can only be resolved by the PTR-TOF-MS and not by the PTR-QMS) becomes quantitatively relevant at low ppb levels. Since these were typical emission levels during the ALIGN-CCUS 2019- 2020 campaign at TCM, it was not possible to quantitatively measure PZ with the PTR-QMS instrument. Impinger sampling followed by offline Ion Chromatography Mass Spectrometry (IC-MS) analysis suffered from a high measurement uncertainty at low ppb levels, meaning that not quantitative PZ data were reported during the ALIGN- CCUS 2019-2020 campaign.

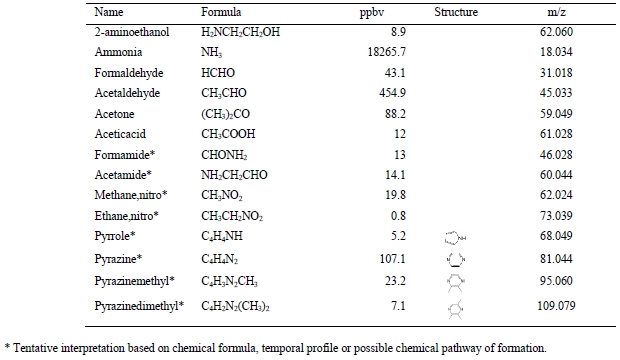

3.3 Measurement of solvent degradation products

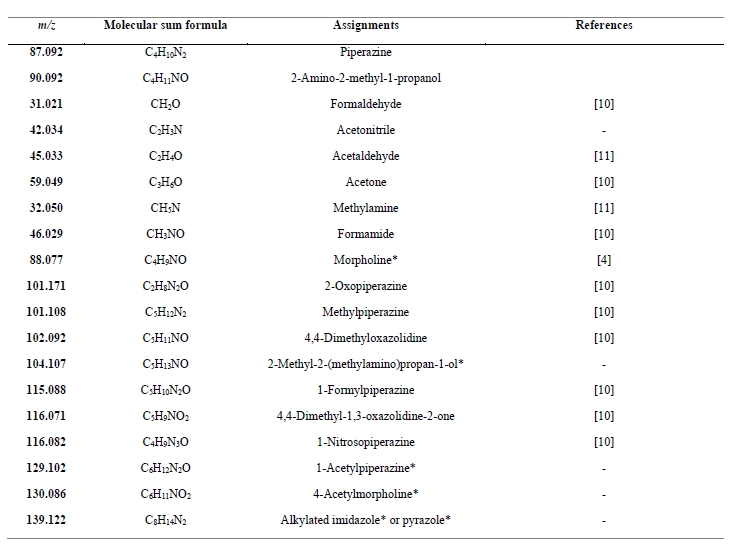

The PTR-TOF-MS analyzer also detected a series of solvent degradation products. The high mass accuracy (typically <10 ppm) of the measurement combined with an isotopic pattern analysis allowed us to identify the elemental composition (i.e., the molecular sum formula) of the decomposition products. Table 3 lists the m/z of the main signals detected in the flue gas, the assigned molecular sum formula and the name of the compound that we assigned (or tentatively assigned) to this signal based on previous work specified in the fourth column. An identification of compounds with a higher degree of confidence warrants complementary analyses by GC-MS or LC- MS.

Table 3. Main m/z signals detected by the PTR-TOF-MS instrument in the flue gas that was emitted to the atmosphere when the amine plant was operated with the CESAR 1 solvent. The molecular sum formula was assigned unambiguously; the assignment to a specific chemical substance was based on chemical plausibility and literature data specified in the “References” column. Assignments marked with an asterisk are tentative.

![]() Conclusions

Conclusions

Amine-based PCCC plants emit a variety of organic chemicals into the atmosphere. Treatment of CCGT flue gas with the CESAR 1 solvent generates ppb-to-ppm levels of AMP in the emission stream. Our study has shown that such emissions can be measured with sophisticated chemical-analytical techniques (PTR-TOF-MS; impinger sampling/IC-MS) but also with less demanding methods that are suitable for routine industrial monitoring purposes (PTR-QMS, FT-IR). Special care must be taken to avoid losses (due to adsorption and/or thermal decomposition of AMP) in the inlet system and to calibrate the online analyzers. Only the PTR-ToF-MS instrument was capable of detecting PZ at low ppb levels, which were typical emission levels during the ALIGN-CCUS campaign. The PTR- TOF-MS analyser is also capable of detecting amine degradation products, 17 of which were observed at significant levels in the flue gas after treatment with the CESAR 1 solvent. The unambiguous identification of these degradation products would, however, require complementary analyses using highly specific offline GC/LC-MSn methods.

While it seems unfeasible to make similar chemical-analytical efforts for emission characterization at each amine- based PCCC plant, TCM and its partners provide the know-how and infrastructure to characterize the emission profile of new solvents.

Acknowledgements

ACT ALIGN-CCUS Project No 271501. This project has received funding from RVO (NL), FZJ/PtJ (DE), Gassnova (NO), UEFISCDI (RO), BEIS (UK) and is co-funded by the European Commission under the Horizon 2020 programme ACT, Grant Agreement No 691712 (www.alignccus.eu).

The authors gratefully acknowledge the staff of TCM DA, Gassnova, Equinor, Shell and TotalEnergies for their contribution and work at the TCM DA facility. The authors also gratefully acknowledge Gassnova, Equinor, Shell, and Total as the owners of TCM DA for their financial support and contributions.

References

- SEPA Scottish Environment Protection Agency. Review of amine emissions from carbon capture systems. Stirling, UK, pages 1–86, 2015.

- Nielsen CJ, Herrmann H, and Weller C. Atmospheric chemistry and environmental impact of the use of amines in carbon capture and storage (ccs). Chem. Soc. Rev., 41 :6684–6704, 2012.

- Låg M, Lindeman B, Instanes C, Brunborg G, and Schwarze P. Health effects of amines and derivatives associated with CO2 capture. 05 2011.

- Morken A, Pedersen S, Kleppe ER, Wisthaler A, Vernstad K, Ullestad Ø, Flø NE, Faramarzi L, and Hamborg ES. Degradation and emission results of amine plant operations from MEA testing at the CO2 technology centre mongstad. Energy Procedia, 114 :1245–1262, 07 2017.

- Zhu L, Schade G, and Nielsen CJ. Real-time monitoring of emissions from monoethanolamine-based industrial scale carbon capture facilities. Environmental science & technology, 47, 11 2013.

- Zhu L, Mikoviny T, Morken AK, Tan W, and Wisthaler A. A compact and easy-to-use mass spectrometer for online monitoring of amines in the flue gas of a post-combustion carbon capture plant. International Journal of Greenhouse Gas Control, 78 :349 – 353, 2018.

- Lindinger W, Hansel A, and Jordan A. On-line monitoring of volatile organic compounds at pptv levels by means of proton-transfer-reaction mass spectrometry (PTR-MS) medical applications, food control and environmental research. International Journal of Mass Spectrometry and Ion Processes, 173(3) :191 – 241, 1998.

- Hansel A, Jordan A, Holzinger R, Prazeller P, Vogel W, and Lindinger W. Proton transfer reaction mass spectrometry: on-line trace gas analysis at the ppb level. International Journal of Mass Spectrometry and Ion Processes, 149-150 :609 – 619, 1995. Honour Biography David Smith.

- Shah MI, Lombardo G, Fostås B, Benquet C, Morken AK, and de Cazenove T. CO2 capture from RFCC flue gas with 30w% MEA at Technology Centre Mongstad, process optimization and performance comparison. In 14th Greenhouse Gas Control Technologies Conference Melbourne, pages 21–26, 2018.

- Wang T. Degradation of Aqueous 2-Amino-2-methyl-1-propanol for Carbon Dioxide Capture. PhD thesis, 2013.

- Cuccia L, Bekhti N, Dugay J, Bontemps D, Louis-Louisy M, Morand T, Bellosta V, and Vial J. Monitoring of the blend 1- methylpiperazine/piperazine/water for post-combustion CO2 capture. Part 1: Identification and quantification of degradation products. International Journal of Greenhouse Gas Control, 76:215 – 224, 2018.

A compact and easy-to-use mass spectrometer for online monitoring of amines in the flue gas of a post-combustion carbon capture plant (2018)

Liang Zhua, Tomáš Mikovinya, Anne Kolstad Morkenb, Wen Tana, Armin Wisthalera,⁎

aDepartment of Chemistry, University of Oslo, P.O. Box 1033, 0315, Oslo, Norway bTechnology Centre Mongstad (TCM), 5954, Mongstad, Norway ⁎ Corresponding author

Abstract

We herein report on the adaptation and deployment of a compact and easy-to-use mass spectrometer for online monitoring of amines in industrial flue gas at ppb to ppm levels. The use of ammonia as a source gas in proton- transfer-reaction mass spectrometry (PTR-MS) greatly simplifies the detection of amines, making it possible to use a low-end commercial instrument version (PTR-QMS 300) for the measurements. We characterized the analytical performance of the instrument (sensitivity, limit of detection, precision, matrix effects) for nine sol- vent amines (monoethanolamine, dimethylaminoethanol, aminomethylpropanol, methyldiethanolamine, di- glycolamine, piperazine, aminoethylpiperazine, methylpiperazine, N-(2-hydroxyethyl)piperazine) and three degradation amines (methylamine, dimethylamine, trimethylamine). The new analyzer was tested and validated in side-by-side measurements with established emission monitoring techniques at the Technology Centre Mongstad (TCM) in Norway. After validation, the instrument was permanently installed on top of the absorber tower to deliver real-time amine emission data to the plant information management system.

This article is behind a paywall. Futher information: https://www.sciencedirect.com/science/article/abs/pii/S1750583618304122?via%3Dihub

Ambient Measurements of Amines by PTR-QiTOF: Instrument Performance Assessment and Results from Field Measurements in the Vicinity of TCM, Mongstad (2016)

Tomáš Mikovinya, Claus J. Nielsena, Wen Tana, Armin Wisthalera*, Liang Zhua, Anne Kolstad Morkenb, Terje Niøten Nilsenb

aDepartment of Chemistry, University of Oslo, P.O. Box 1033 Blindern, 0315 Oslo, Norway bCO2 Technology Centre Mongstad (TCM DA), 5954 Mongstad, Norway *Corresponding author

© 2017 The Authors. Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license. Peer-review under responsibility of the organizing committee of GHGT.

Abstract

A PTR-QiTOF instrument was deployed in the field in the vicinity of the CO2 Technology Center Mongstad (TCM) for measuring amines in ambient air. The observed single-to-double-digit pptv levels of dimethylamine (DMA) and trimethylamine (TMA) are comparable to natural background values reported in the literature for these species. No indication was found that these small alkylamines stem from industrial activities at Mongstad. Monoethanolamine (MEA) was observed at single-digit pptv levels, but further analytical work is needed to validate measurements at such low concentrations. No indication was found that small enhancements in ambient MEA levels were caused by emissions from TCM. No other industrial amines (2-amino-2- methylpropanol, diethylamine and piperazine) were detected in ambient air. According to the current state of knowledge, the observed levels of amines pose no harm to human health or the environment.

1. Introduction

Amine-based capture of carbon dioxide (CO2) results in the release of trace amounts of amines to the atmosphere. While amines are nowadays routinely monitored in stack gas, the detection of amines under highly diluted atmospheric conditions remains an analytical challenge [1]. Proton-Transfer-Reaction Mass Spectrometry (PTR-MS) has been successfully used for on-line monitoring of amines in stack gas [2,3] and in atmosphere simulation chambers [4,5,6]. Recently, the ultra-sensitive proton-transfer-reaction quadrupole ion guide time-of-flight mass spectrometer (PTR-QiToF-MS) has become available [7], which is capable of detecting trace gases at single-digit pptv levels (1 pptv = 1 pmol mol-1 = 10-12 v/v). In the present study, we have used this novel analytical tool for carrying out exploratory measurements of amines in ambient air in the vicinity of the CO2 Technology Centre Mongstad (TCM).

2. Methods

Ambient air measurements were carried out at Sunsbø (60°46’10.1″N, 5°09’08.6″E), Sande (60°50’56.6″N, 5°00’21.0″E) and Mongstad West (60°48’45.7″N, 5°00’43.4″E) from Aug 6 – 28, Aug 28 – Sept 10 and Sept 10 – 25, 2015, respectively. The geographic location of the three measurement sites and of TCM is shown in Figure 1.

Fig. 1. Geographical map showing the locations of the measurement sites at Sunsbø, Sande and Mongstad West and of the Technology Center Mongstad (TCM).

PTR-MS is an on-line chemical ionization (CI) technique for atmospheric trace gases that has been routinely deployed in atmospheric chemistry field studies over the past decade [8]. Only recently, the ultra-sensitive PTR- QiTOF-MS instrument version has become available which detects gaseous analytes at single-digit pptv-levels [7].

We operated the PTR-QiTOF instrument in the routine mode of operation recommended by the manufacturer (H3O+ CI; drift tube pressure 3.8 mbar, drift tube temperature 60 °C, reduced electric field strength 120 Td with 1 Td = 10-17 V cm2). Mass spectra were recorded in the m/z 15 to m/z 510 range, but only selected signals corresponding to protonated methylamine, dimethylamine (DMA) and ethylamine, trimethylamine (TMA), monoethanolamine (MEA), 2-amino-2-methylpropanol (AMP), diethylamine and piperazine, respectively, were analyzed in detail. The list of target amines was taken from a previous study [1]. The PTR-TOF Data Analyzer v4.44 was used for data analysis [9]. 2-minute and 1-hour averages were generated from the data output.

An optimized inlet system was used for minimizing inlet losses of amines. Ambient air was sampled at a flow rate of 12 liters per minute trough a passivated stainless steel tube (material: SilcoNert® 2000, outer diameter: 6.35 mm, length: 115 cm, temperature: 60 °C). The PTR-QiTOF instrument sub-sampled a flow of 0.5 liters per minute through a heated capillary (material: PEEK, outer diameter: 1.59 mm, temperature: 60 °C). No evidence for inlet losses was found when ambient air was spiked with known amounts of DMA and TMA at pptv levels.

Amine-free air generated from compressed and catalytically cleaned (Pt/Pd at 325 °C) ambient air was periodically (every 12 hours for 30 minutes) fed to the inlet system for instrumental background determination.

Instrumental response factors for DMA, TMA and MEA were calculated from ion-molecule reaction kinetics using the molecular properties reported previously [4,5,6]. The estimated accuracy of the reported volume mixing ratios is ±20% for volume mixing ratios above 10 pptv.

TCM is part of a large industrial complex (refinery, power plant, oil terminal) at Mongstad which is located in a pristine coastal environment. Oil and gas tracers were used for distinguishing between periods when the outflow from the Mongstad complex was advected to the sampling sites and periods when natural background air was sampled. TCM was in operation during the ambient air measurement campaign, with MEA being used for CO2 capture.

3. Results

AMP, diethylamine and piperazine were not detected at levels above 10 pptv in the recorded mass spectra. It was not possible to measure these species at single-digit pptv levels due to mass spectral interferences. The PTR-QiTOF instrument, in its routine mode of operation, was not capable of detecting methylamine. The abundant O + signals distorted the mass spectrum in the region where methylamine is detected.

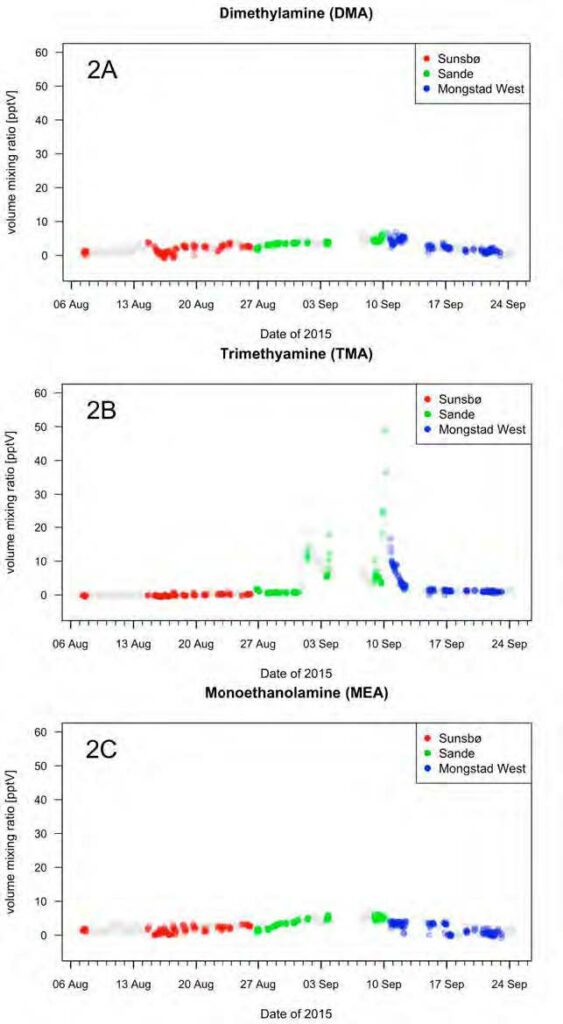

The hourly average time series of DMA, TMA and MEA are shown in Figures 2a, 2b and 2c, respectively. The color-coded data points identify the time periods when the outflow from the Mongstad industrial complex was advected to the sampling site.

DMA was observed at single-digit pptv levels, which is at or close to the instrumental detection limit. The detection of amines at such low concentrations is an analytical challenge and all single-digit pptv data reported herein should be taken with caution. More analytical validation work is needed in this concentration regime. The 2- minute average data show episodic short-term enhancements in the 10 to 22 pptv range at all three measurement sites. These enhancements were found both in natural background air and in the outflow from the Mongstad complex.

TMA levels were typically close to zero, with the exception of an episode lasting from Sept 1 to 12 when hourly average volume mixing ratios up to 49 pptv were recorded. Enhanced levels of TMA were observed at the Sande and the Mongstad West site, both in natural background air and in the outflow from the industrial site.

MEA levels were also in the single-digit pptv range. Yet again, these concentrations should be interpreted with caution. A 1-2 pptv enhancement was observed in the period from Aug 31 to Sept 10, both in natural background air and in the Mongstad outflow. This comes as a surprise as MEA is not believed to have natural sources. Further research is warranted to confirm these findings and exclude potential signal interferences for MEA.

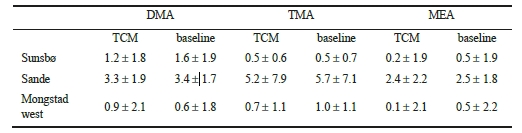

The time series data indicate that amine levels were not enhanced in the Mongstad outflow as compared to natural background conditions. This is also reflected in the overall statistical analysis summarized in Table 1.

4. Discussion and Conclusions

A PTR-QiTOF instrument was successfully deployed in the field for the first time to measure amines in ambient air. The observed single-to-double-digit pptv levels of DMA and TMA are comparable to coastal background values reported in the literature for these species [10]. No indication was found that these small alkylamines stem from industrial activities at Mongstad. According to the current state of knowledge, the observed levels of alkylamines pose no direct or indirect harm to human health or the environment.

TCM was operating on MEA during the ambient measurements. Single-digit pptv levels of MEA were observed in ambient air, but no indications were found that these small enhancements were caused by emissions from TCM. Further analytical work is, however, needed to validate MEA measurements at such low concentrations. No other industrial amines (AMP, diethylamine and piperazine) were detected.

Fig. 2. Hourly average time series of DMA, TMA and MEA amine as measured at Sunsbø, Sande and Mongstad West in August and September of 2015. The color-coded data points identify the time periods when the Mongstad outflow was advected to the sampling sites.

Table 1. Average mixing ratios (in pptv) of DMA, TMA and MEA as observed at the Sunsbø, Sande and Mongstad West sites, respectively, when the Mongstad plume was advected and under natural background conditions. No statistically significant enhancement of amines was found in the outflow from the Mongstad industrial complex as compared to natural background conditions.

References

- Vik AF, Rostkowski P. Amines in ambient air at TCM – Monitoring program May 2012 – April 2013, NILU Report OR 31/2015 (2015)

- Zhu L, Schade GW, Nielsen CJ. Real time monitoring of emissions from monoethanolamine-based industrial scale carbon capture facilities. Environ Sci Technol. 2013; 47, 14306-14314

- Morken AK, Nenseter B, Pedersen S, Chhaganlal M, Feste JK, Tyborgnes RB, Ullestad Ø, Ulvatn H, Zhu L, Mikoviny T, Wisthaler A, Cents T, Bade OM,GKnudsen J, de Koeijer G, Falk-Pedersen O, Hamborg ES. Emission results of amine plant operations from MEA testing at the CO2 Technology Centre Mongstad. Energy Procedia 2014; 63, 6023–6038

- Nielsen CJ, D´Anna B, Bossi R, Bunkan AJC, Dithmer L, Glasius M, Hallquist M, Hansen AMK, Lutz A, Salo K, Maguta MM, Nguyen Q, Mikoviny T, Müller M, Skov H, Sarrasin E, Stenstrøm Y, Tang Y, Westerlund J, Wisthaler A. Atmospheric Degradation of Amines (ADA). Summary report from atmospheric chemistry studies of amines, nitrosamines, nitramines and amides, University of Oslo, Oslo, Norway 2012; ISBN 978-82-992954-7-5, http://urn.nb.no/URN:NBN:no-30510

- Nielsen CJ, D’Anna B, Karl M, Aursnes M, Boreave A, Bossi R, Bunkan AJC, Glasius M, Hansen AMK, Hallquist M, Kristensen K, Mikoviny T, Maguta MM, Müller M, Nguyen Q, Westerlund J, Salo K, Skov H, Stenstrøm Y, Wisthaler A. Atmospheric Degradation of Amines (ADA). Summary report: Photo-oxidation of methylamine, dimethylamine and trimethylamine, NILU Report OR 2/2011

- Nielsen CJ, D’Anna B, Dye C, George C, Graus M, Hansel A, Karl M, King S, Musabila M, Müller M, Schmiedbauer N, Stenstrøm Y, Wisthaler A. Atmospheric Degradation of Amines (ADA). Summary report: Gas phase photo-oxidation of 2-aminoethanol (MEA), NILU Report OR 8/2010

- Sulzer P, Hartungen E, Hanel G, Feil S, Winkler K, Mutschlechner P, Haidacher S, Schottkowsky R, Gunsch D, Seehauser H, Striednig M, Jürschik S, Breiev K, Lanza M, Herbig J, Märk JL, Märk TD, Jordan A. A Proton Transfer Reaction-Quadrupole interface Time-Of-Flight Mass Spectrometer (PTR-QiTOF): High speed due to extreme sensitivity. Int J Mass Spectrom 2014; 368:1–5

- De Gouw J, Warneke C. Measurements of volatile organic compounds in the earth’s atmosphere using proton-transfer-reaction mass spectrometry, Mass Spectrom Rev 2007; 26, 2:223–257

- Müller M, Mikoviny T, Jud W, D’Anna B, Wisthaler A. A new software tool for the analysis of high resolution PTR-TOF mass spectra, Chemom Intell Lab Syst 2013; 127:158–165

- Ge X, Wexler AS, Clegg SL. Atmospheric amines – Part I. A review, Atmos Environ 2011; 45:524-546

Emission results of amine plant operations from MEA testing at the CO2 Technology Centre Mongstad (2014)

Anne K. Morkena,b, Bjarne Nenseterb, Steinar Pedersenb, Milan Chhaganlala,b, Jane K. Festea,b, Rita Bøe Tyborgnesa,b, Øyvind Ullestada,b, Helge Ulvatna,b, Liang Zhuc, Tomas Mikovinyc, Armin Wisthalerc, Toine Centsa,d, Otto M. Badee, Jacob Knudsene, Gelein de Koeijerb, Olav Falk-Pedersena,f, Espen S. Hamborga,b,*

aCO2 Technology Centre Mongstad (TCM DA), 5954 Mongstad, Norway bStatoil ASA, P.O. Box 8500, 4035 Stavanger, Norway cUniversity of Oslo, Department of Chemistry, P.O. Box 1033 Blindern, 0315 Oslo, Norway dSasol Technology, PO Box 5486, Johannesburg 2000, South Africa eAker Solutions, P. O. Box 222, 1326 Lysaker, Norway fGassnova SF, Dokkvegen 10, 3920 Porsgrunn, Norway *Corresponding author

doi: 10.1016/j.egypro.2014.11.636

Abstract

Extensive atmospheric emission monitoring has been conducted at the CO2 Technology Centre Mongstad (TCM DA) during amine based post-combustion CO2 capture. The TCM DA amine plant was operated with an aqueous monoethanolamine (MEA) solvent system, treating flue gas from a combined heat and power (CHP) plant. Emission monitoring was conducted by a Fourier Transform Infrared (FTIR) Spectroscopy analyzer, a Proton Transfer Reaction Time-of-Flight Mass Spectrometry (PTR-TOF- MS) analyzer, and manual isokinetic sampling followed by off-line analysis in the laboratory.

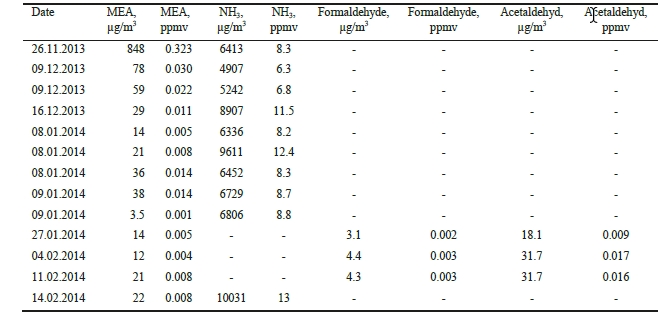

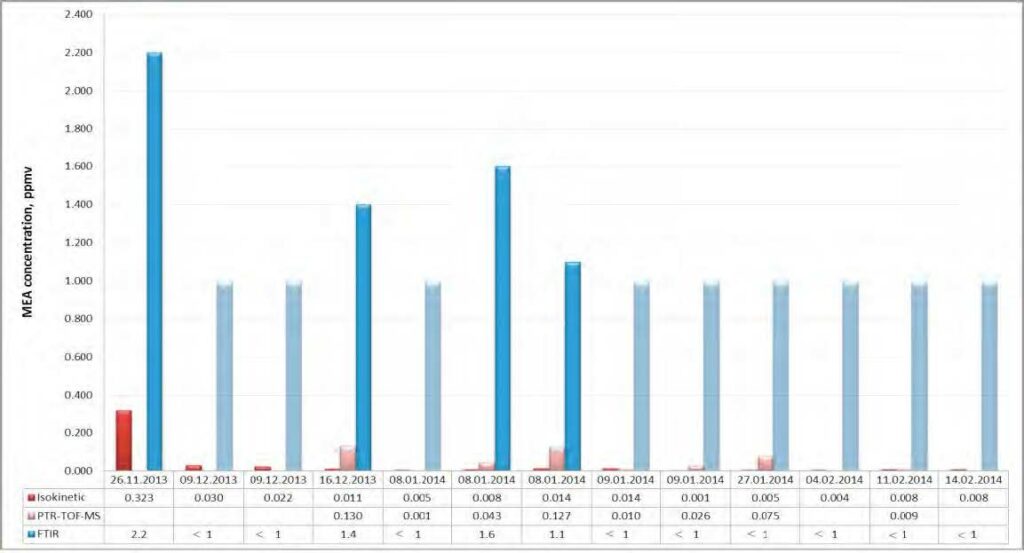

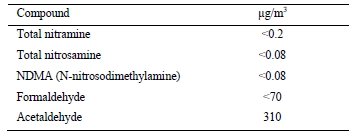

Atmospheric emissions of MEA were very low throughout the entire campaign, ranging from a few to a few hundred parts per billion (ppb, 1 ppb = 10-9 v/v). Atmospheric emissions of MEA amine based degradation products such as nitrosamines and nitramines were below detectable levels. Atmospheric emissions of ammonia (NH3) were in the low ppm range. Methylamine was emitted at low ppb range.

Absorber wash water sections were found to effectively reduce atmospheric emissions from amine based solvent system.

1. Introduction

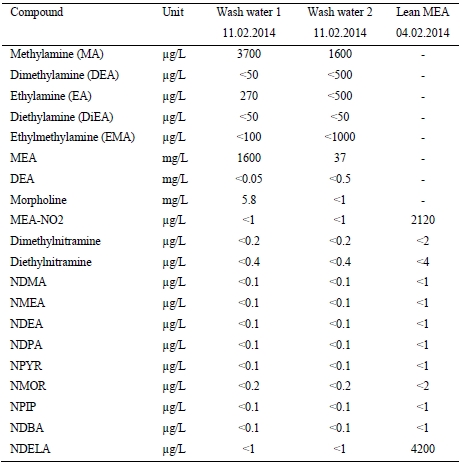

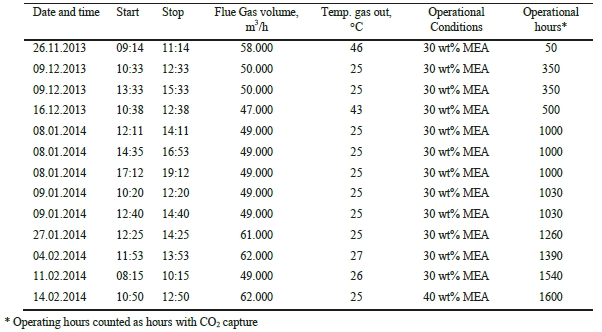

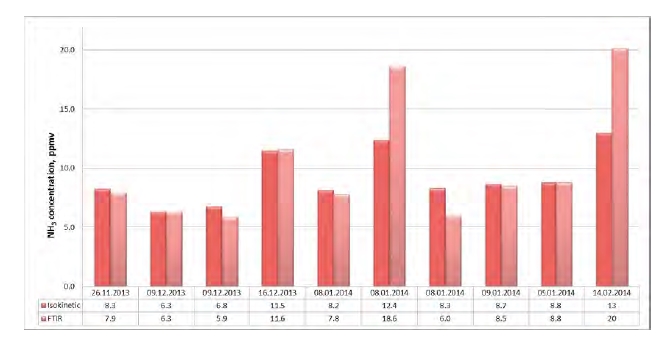

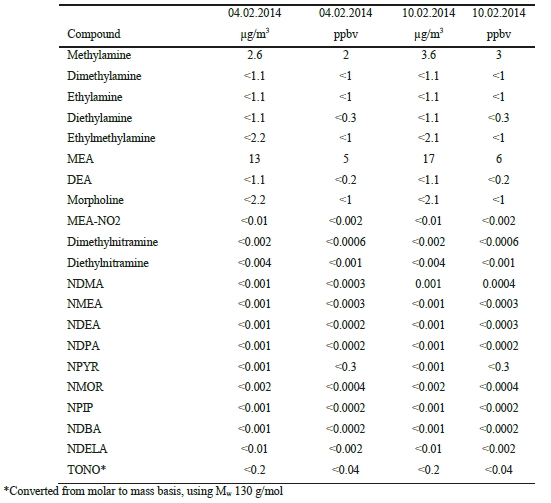

The CO2 Technology Centre Mongstad (TCM DA) has in collaboration with partners undertaken several months test using the non-proprietary aqueous monoethanolamine (2-aminoethanol, MEA) solvent system at 30 wt% and 40 wt% in an attempt to characterize the performance and atmospheric emissions from such operations [1,2,3]. The operations were carried out at a considerably large scale of about 50.000 Sm3/h of flue gas supply flow rates from a combined heat and power (CHP) plant, as described elsewhere [1,2,3]. In the CHP plant, the natural gas is combusted in a gas turbine and the flue gas content and characteristics are similar to those of a combined cycle gas turbine (CCGT) power plant. TCM DA has made significant investment in equipment and instrumentation for monitoring of stack emissions. Continuous efforts are being done to improve sampling methods, sampling lines and the instrumental analysis.